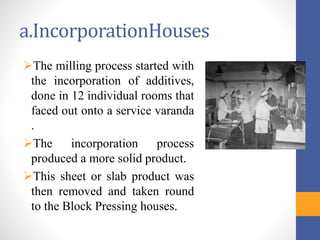

Cordite is a smokeless propellant developed in the UK in 1889 to replace gunpowder in firearms. It is a double-base propellant made of nitrocellulose, nitroglycerin and petroleum jelly. Its production involved complex multi-step processes including the manufacture of nitroglycerin through nitration of glycerin with mixed acid, and mixing it with nitrocellulose. The mixture was pressed into cords and dried. Cordite provided a steady gas pressure and had less smoke than gunpowder, making it suitable for firearms. Its production required careful control of temperature and acid levels as cordite can become unstable and explode if raw materials are improperly combined.