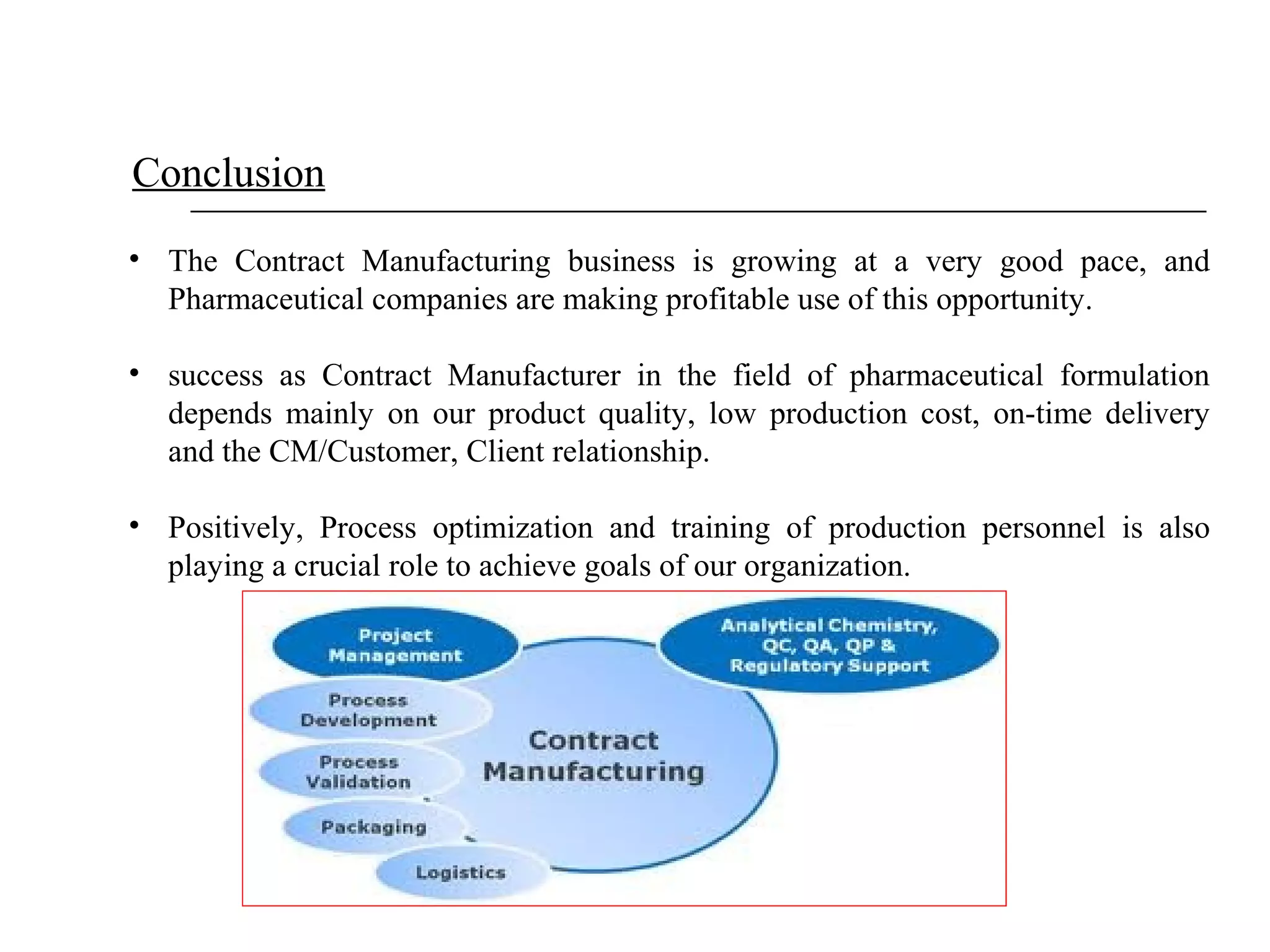

Contract manufacturing organizations (CMOs) provide comprehensive outsourcing services to pharmaceutical companies, including drug development, manufacturing, and quality testing. CMOs offer advantages like lower costs, flexibility, and expertise. They have emerged as an important part of pharmaceutical companies' manufacturing strategies as R&D costs rise. Success for CMOs depends on maintaining high product quality, competitive costs, on-time delivery, and strong relationships with customers. CMOs allow pharmaceutical companies to focus on core functions while limiting capital costs and risks of manufacturing.