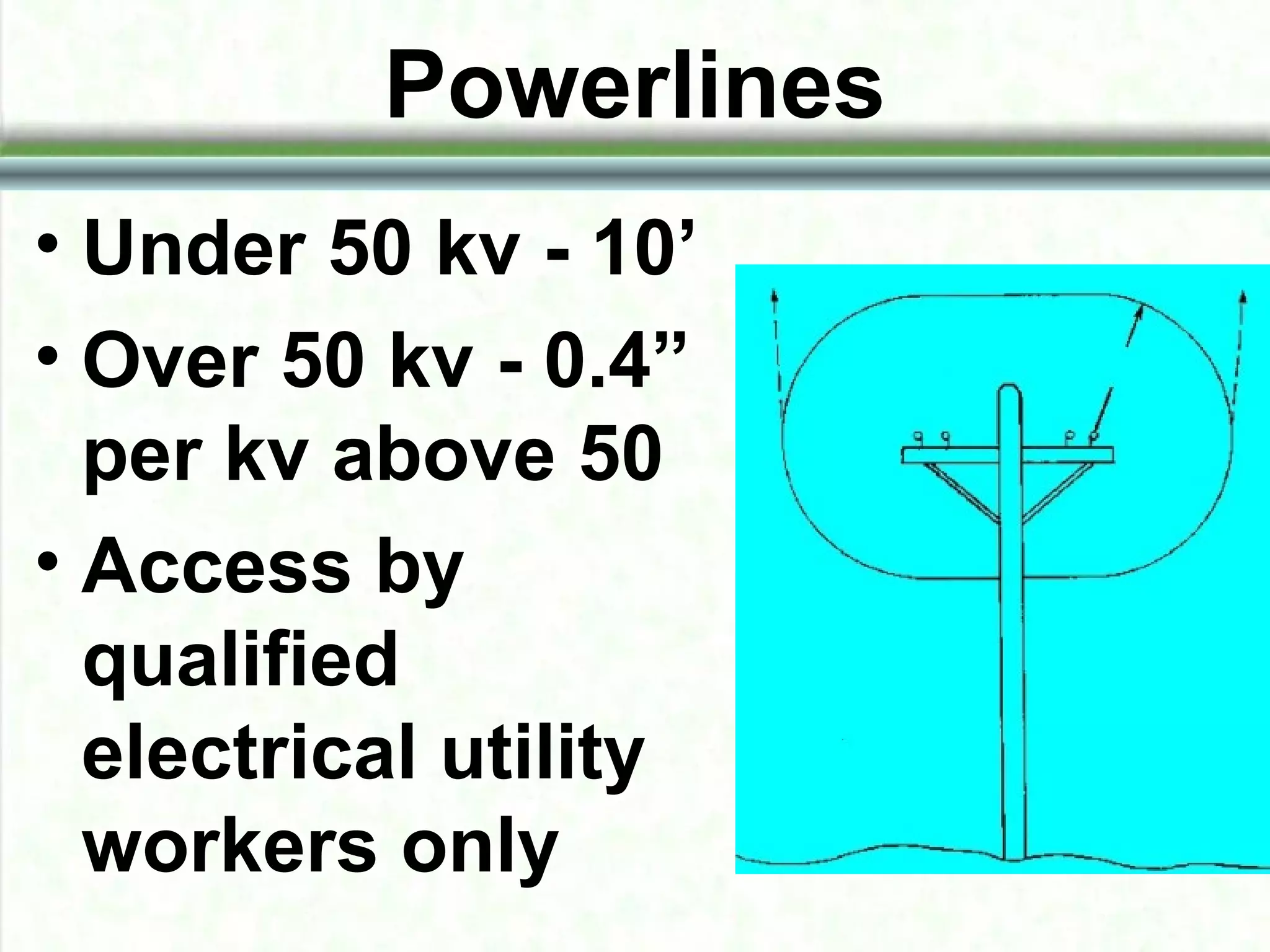

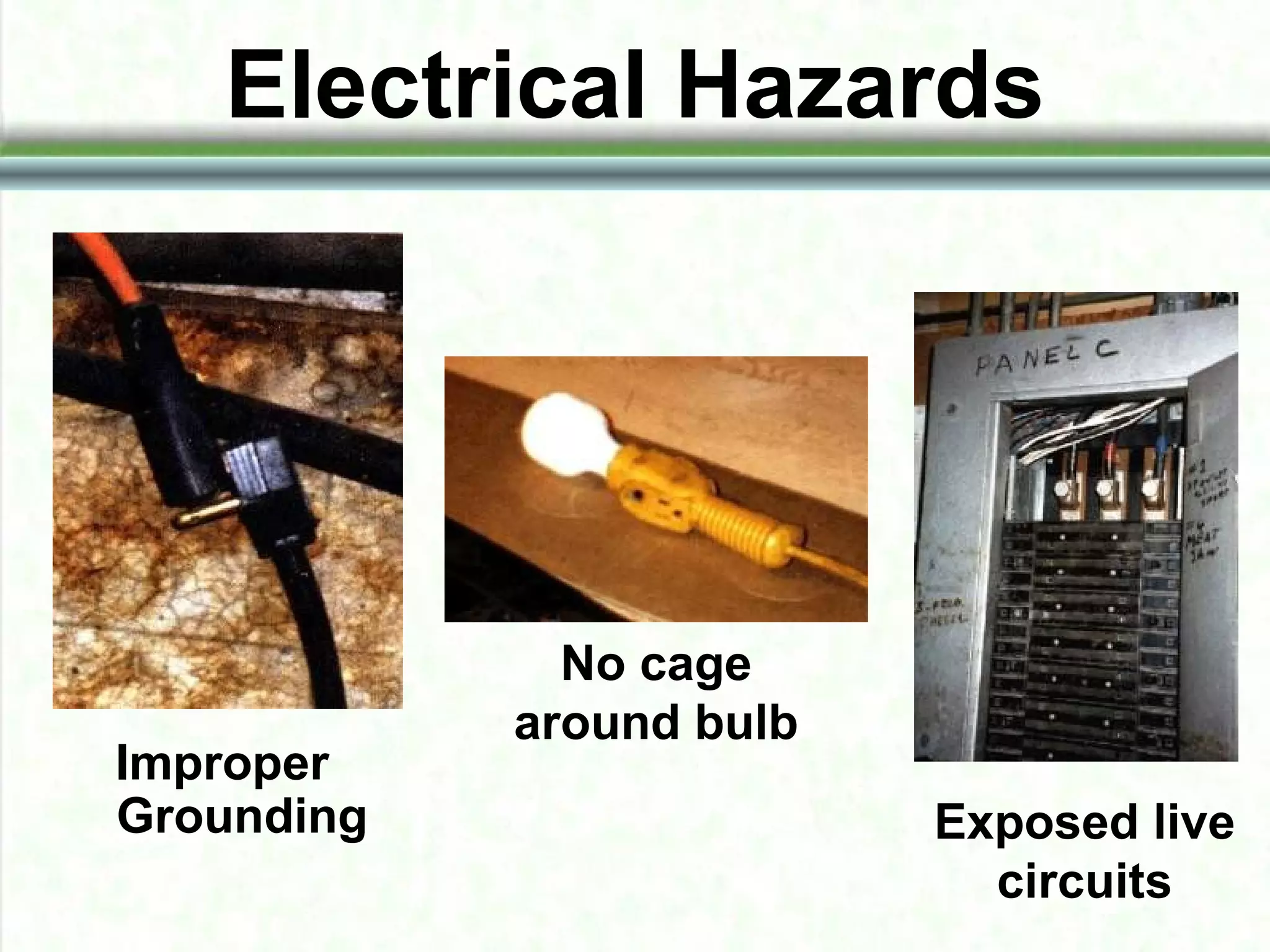

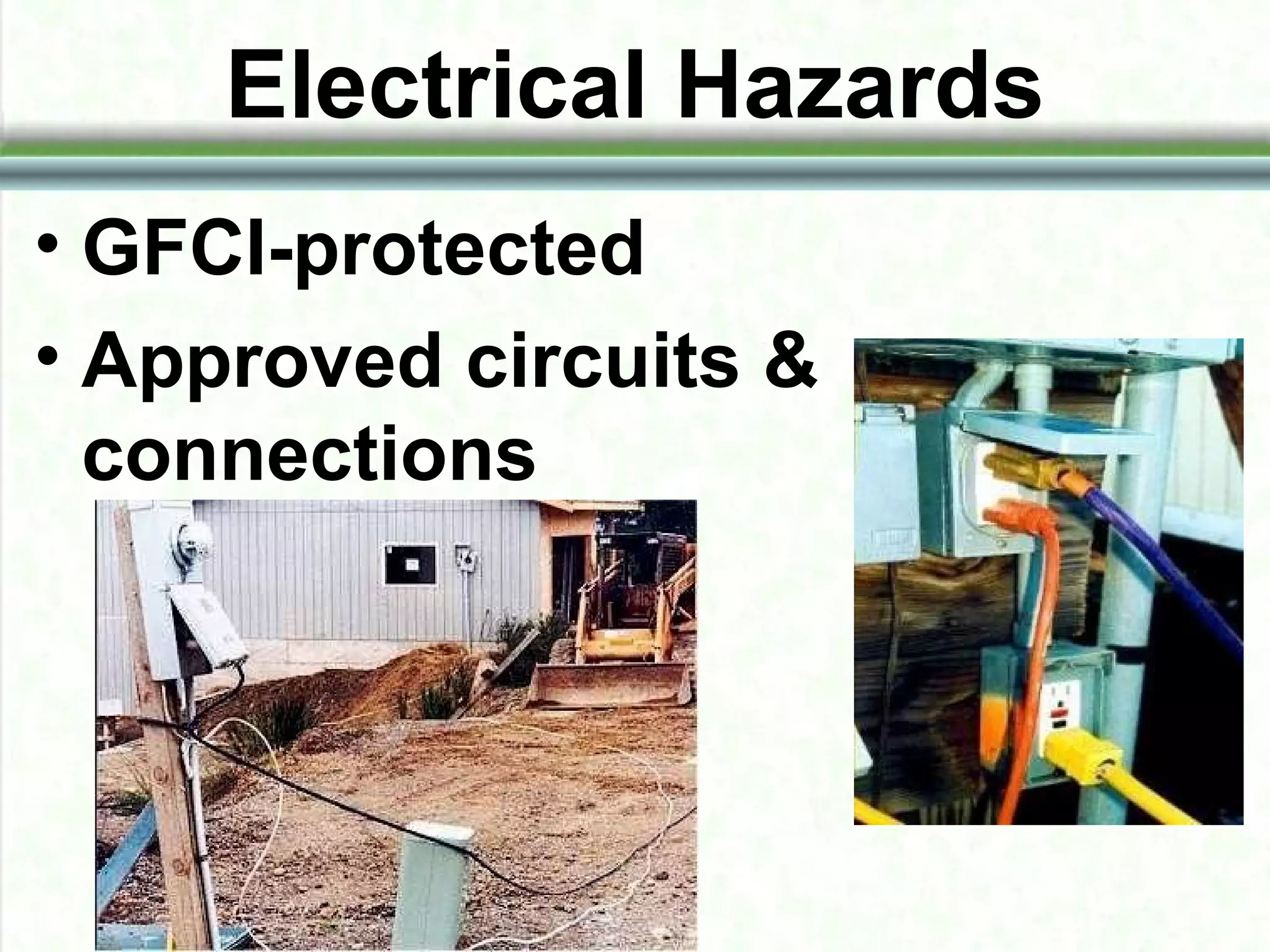

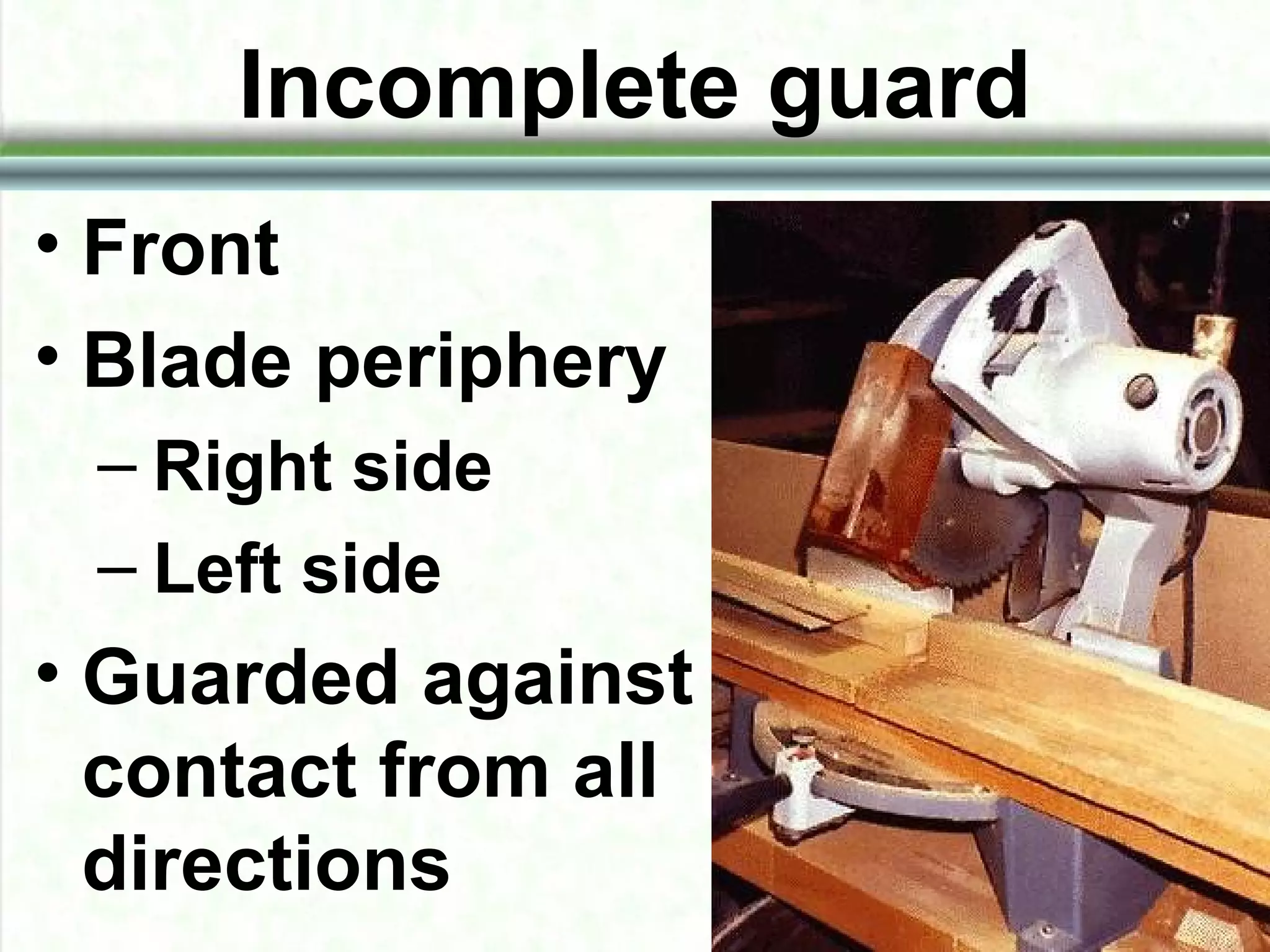

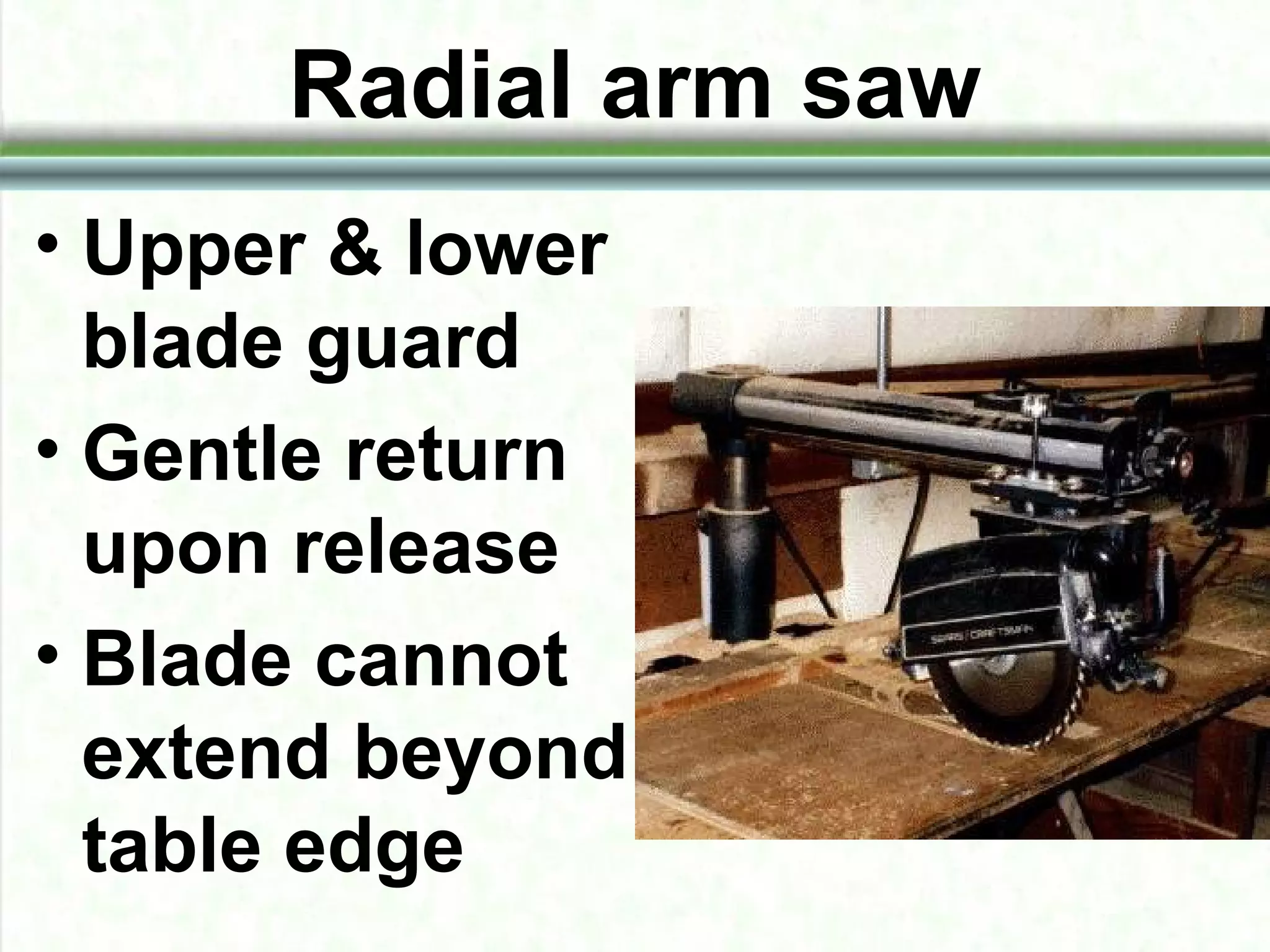

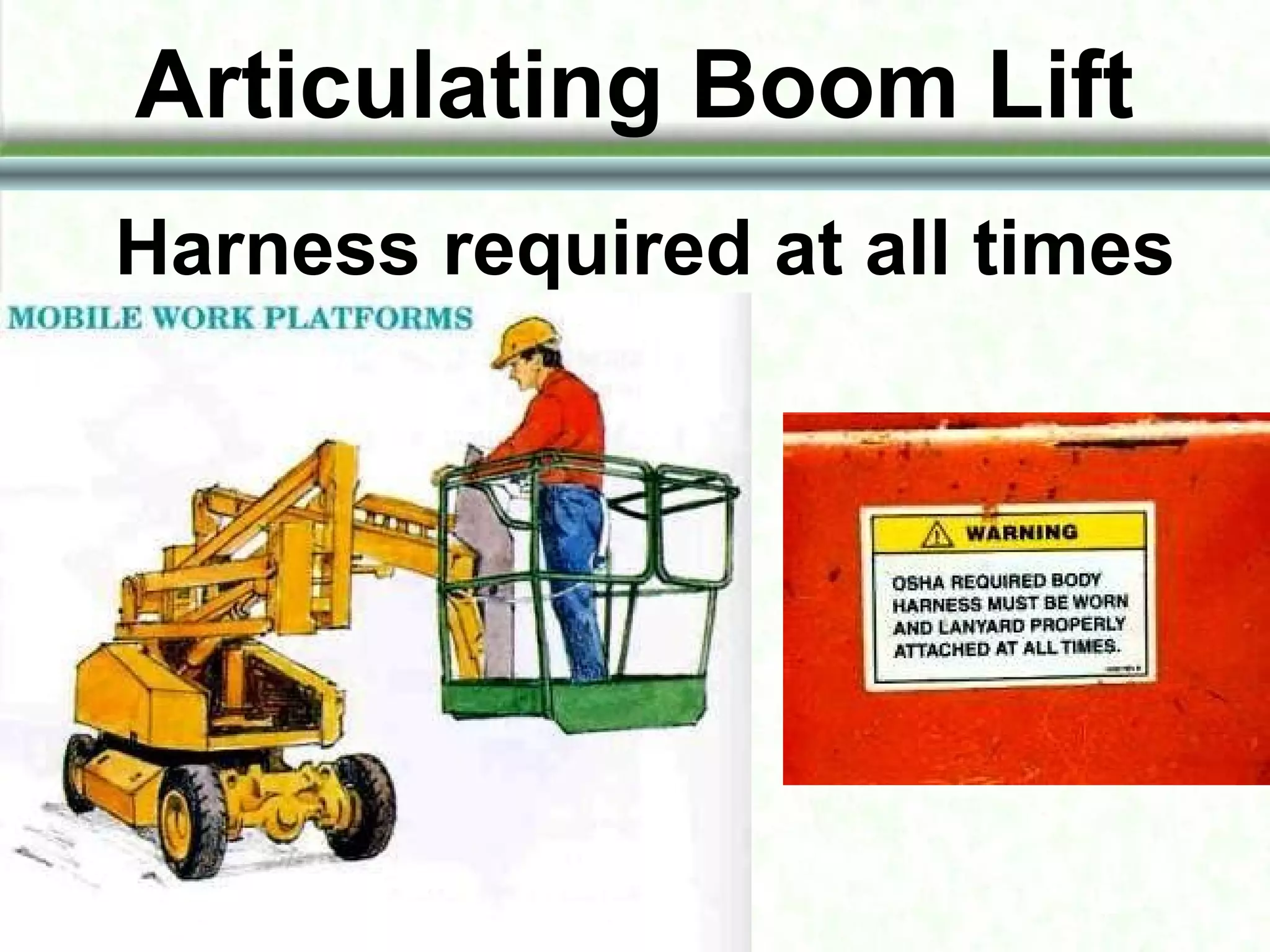

This construction self-inspection guide outlines the most common safety violations in order to prevent injuries and fatalities. It summarizes regulations around fall protection, electrical safety, trenching, scaffolding, stairways, ladders, power lines, guardrails, machine guarding, personal protective equipment, housekeeping, and other construction hazards. Adhering to written safety programs and proper use of safety equipment are emphasized as essential for accident prevention.