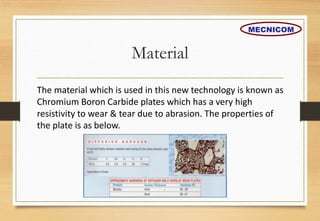

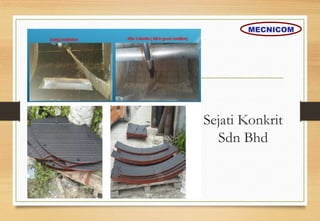

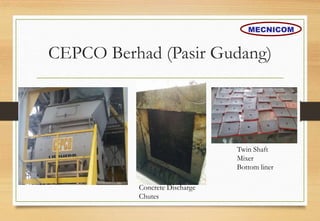

This document discusses wear resistant plates that can be used as liners in concrete mixers. It notes that using these plates can reduce costs through decreased need for replacement parts, downtime, and material purchases compared to traditional cast steel liners. The document outlines Mecnicom's services in installing and monitoring the plates, lists existing customers in Malaysia and the Middle East, and describes the chromium boron carbide material used in the plates that makes them highly resistant to wear and abrasion.