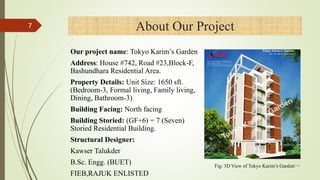

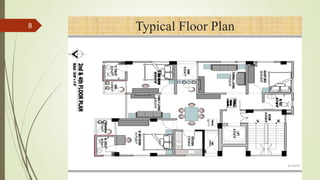

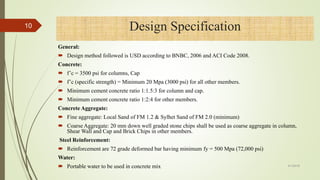

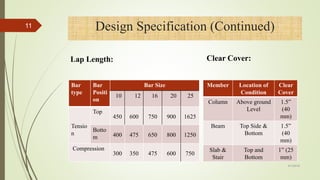

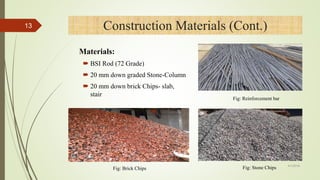

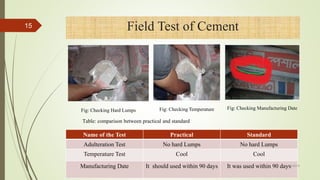

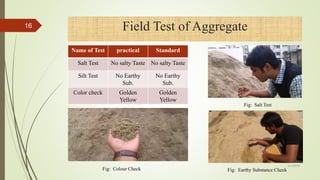

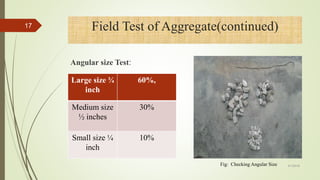

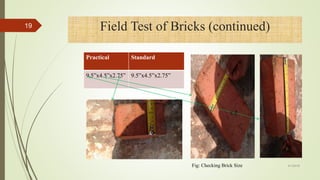

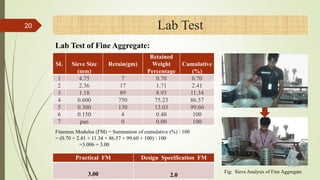

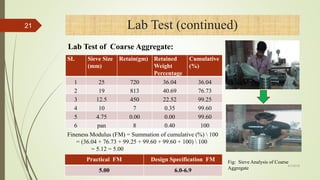

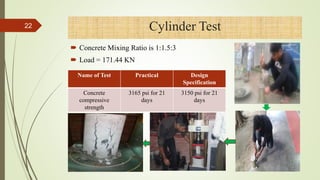

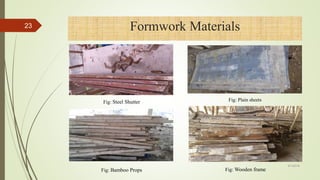

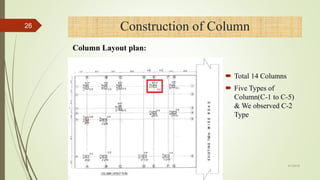

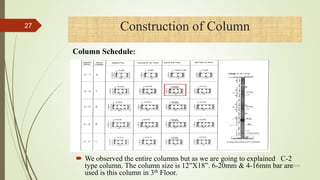

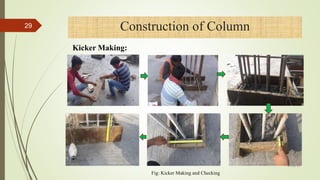

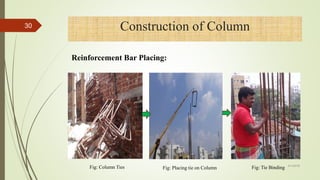

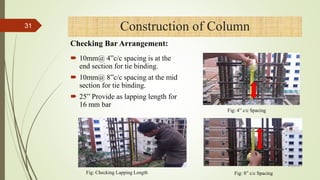

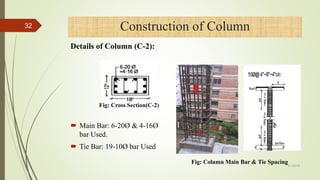

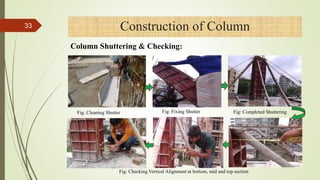

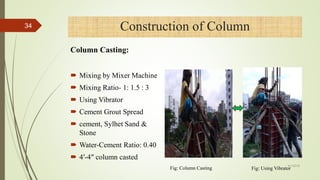

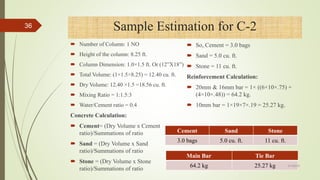

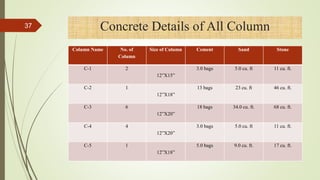

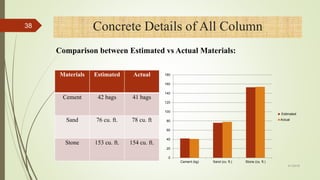

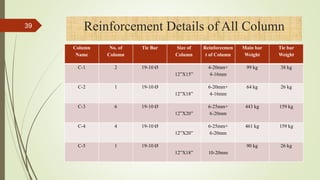

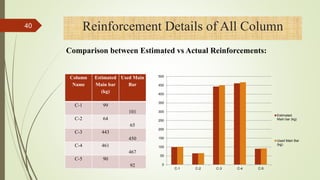

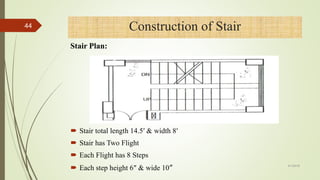

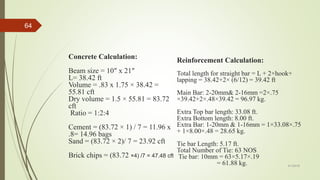

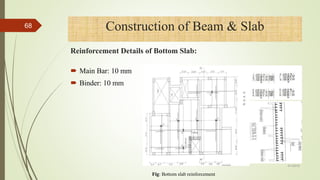

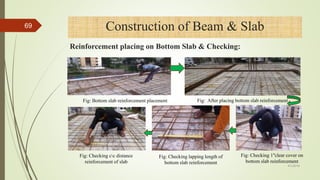

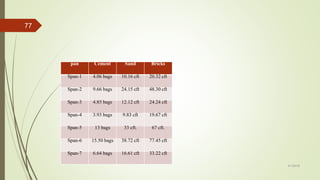

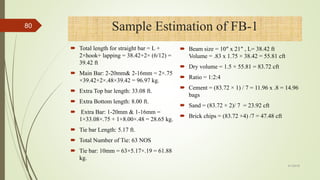

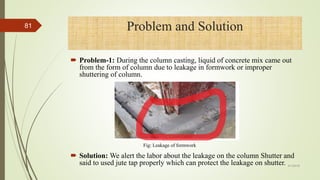

The document summarizes the construction process of columns for a seven storied residential building. It describes the process of forming kickers, placing reinforcement bars, shuttering, casting, and curing concrete columns. It provides details on the types and sizes of columns constructed, reinforcement details, and estimates of required construction materials. Laboratory and field tests were conducted to ensure quality of materials and construction methods.