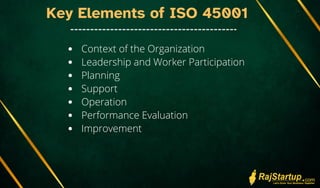

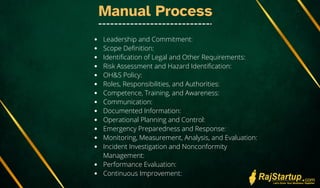

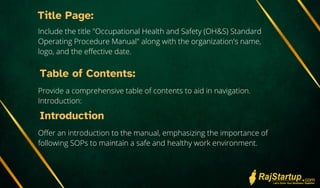

The document provides an overview of ISO 45001, an international standard for occupational health and safety management systems aimed at improving workplace safety and compliance. It outlines the key elements, benefits, and processes for certification, while also detailing the creation of a standard operating procedures manual and outlining essential dos and don'ts for successful implementation. Organizations are encouraged to engage in risk assessment, worker involvement, and continuous improvement as part of their health and safety strategy.