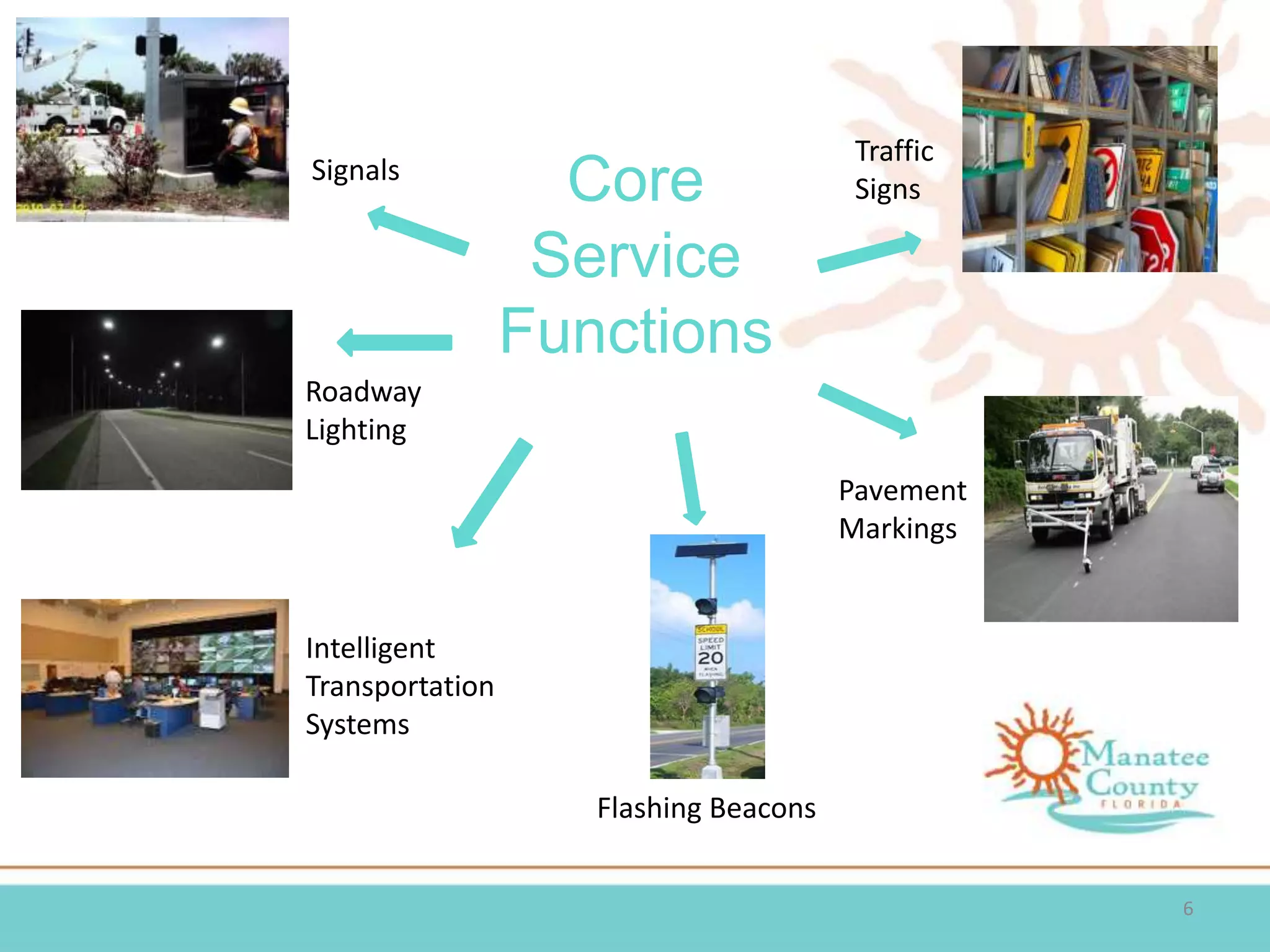

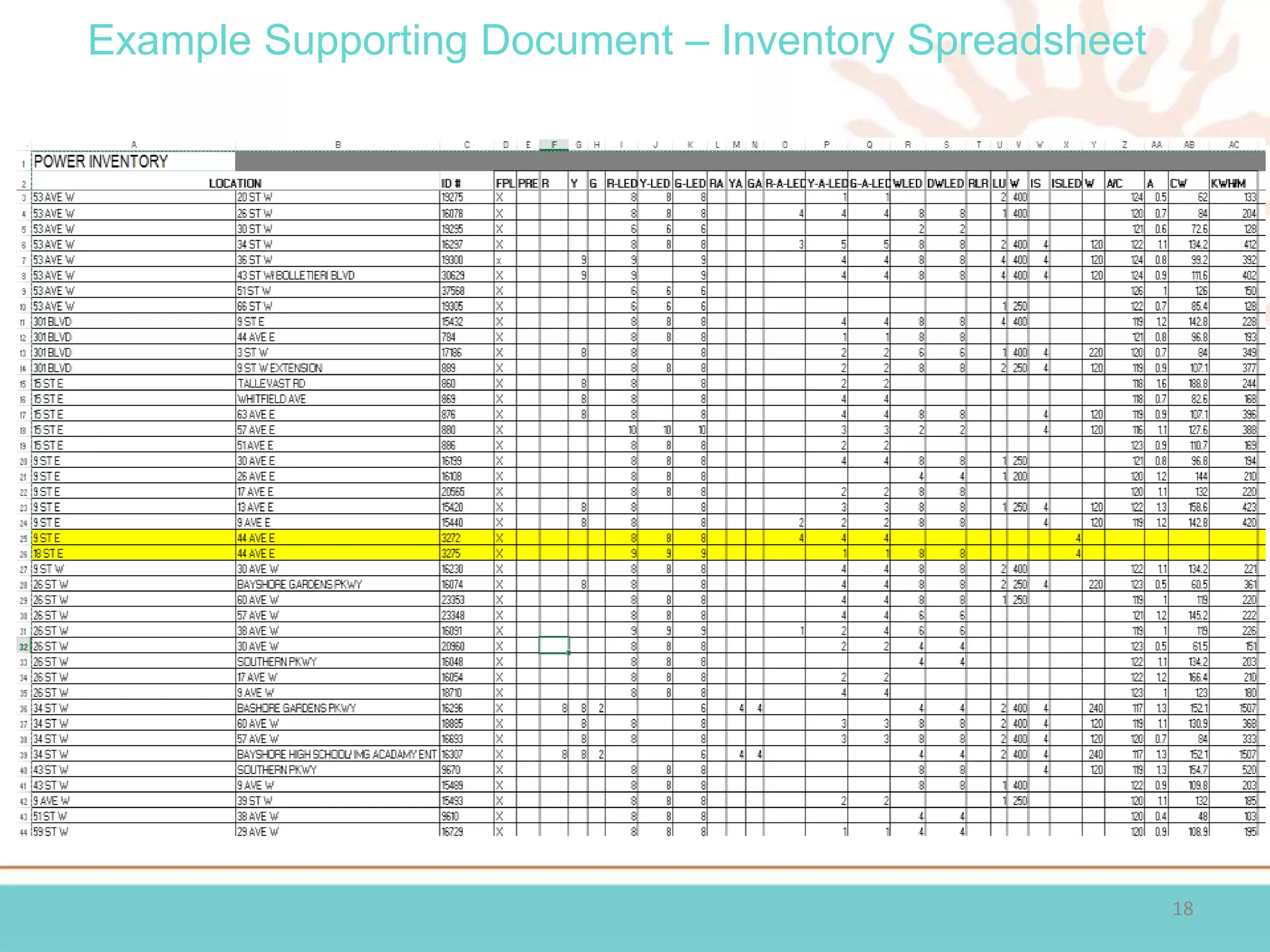

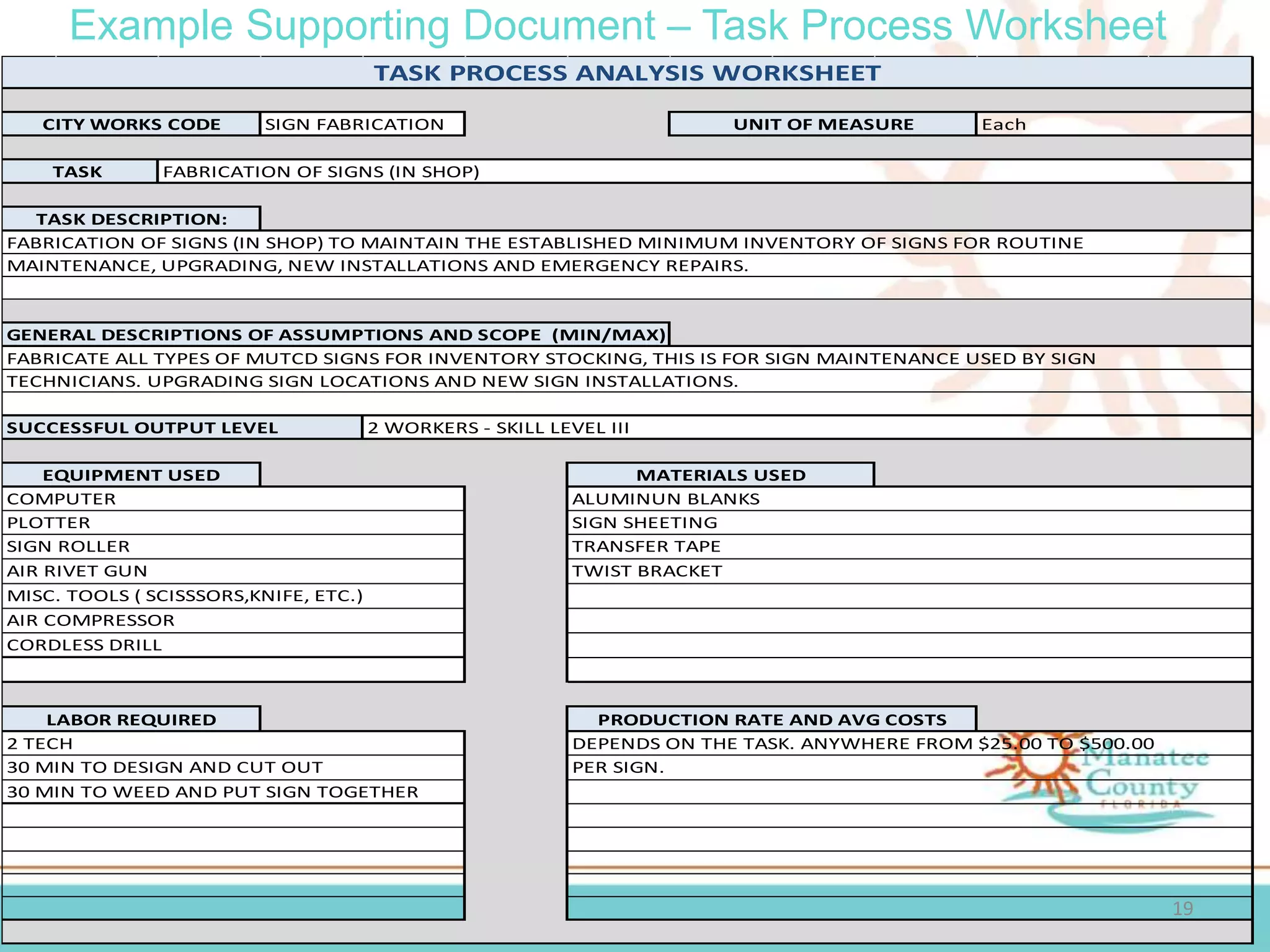

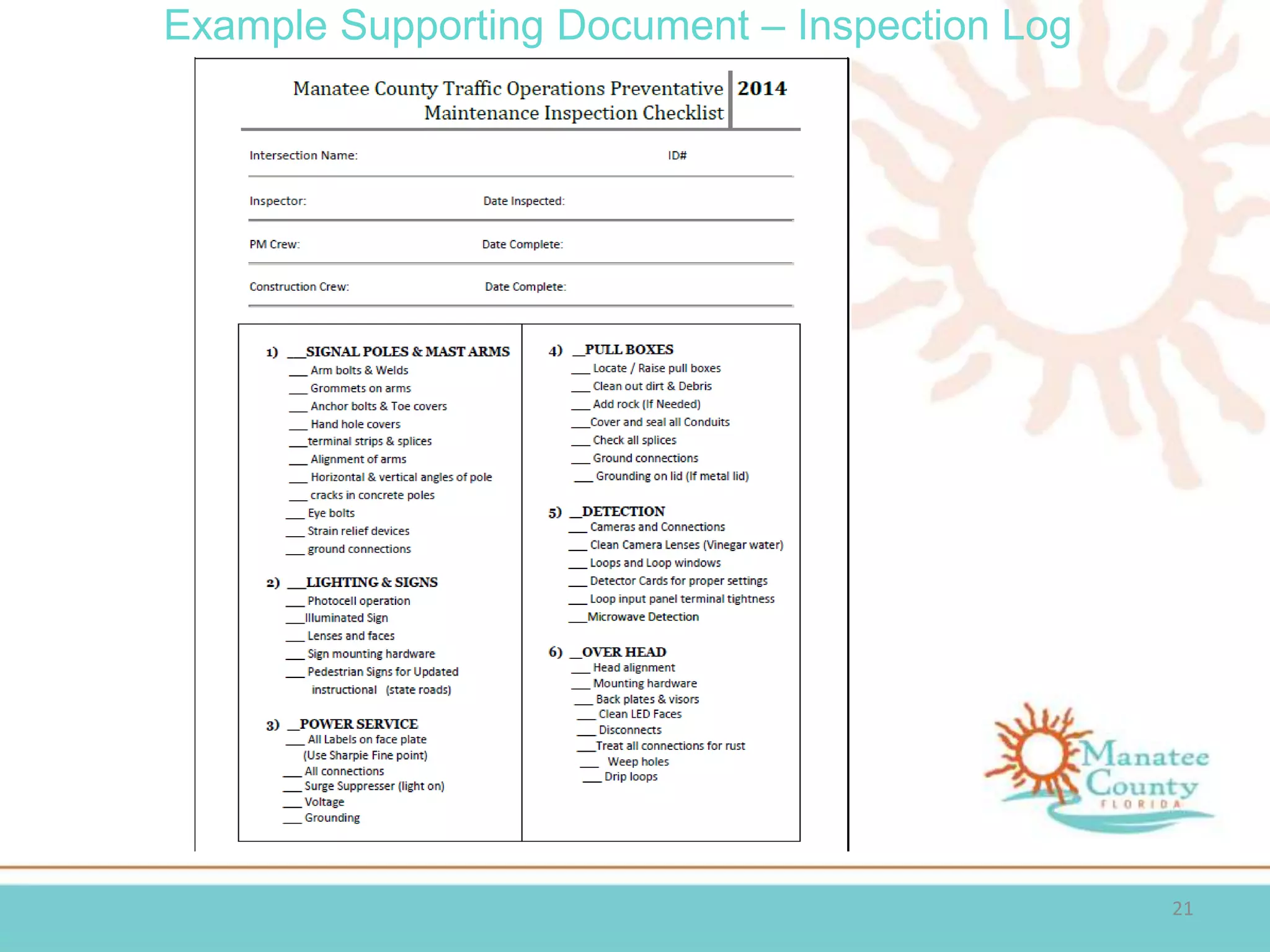

The document presents Manatee County's Comprehensive Maintenance Plan (CMP) for traffic control devices. The CMP defines procedures, tasks and objectives to maintain core functions like traffic signals, signs, and markings. It includes maintenance procedures, inventories, inspections, priorities and supporting documents. The CMP aims to provide accountability through a methodical, measurable approach. Challenges in developing the CMP included resources and buy-in, while opportunities include funding options and changes in leadership supporting the new approach.