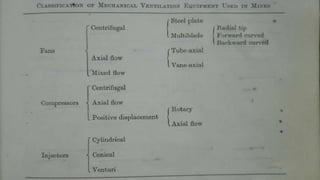

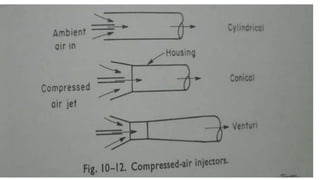

This document classifies and describes different types of mechanical ventilation devices used in mines. It discusses fans, compressors, injectors, and the different types of fans including centrifugal fans, steel plate fans, multi-blade fans, axial flow fans, and mixed flow fans. Compressors are described as being similar to high pressure fans. Injectors are explained as using compressed air to induce airflow into ducts or pipes and are simpler and cheaper than fans but less efficient.