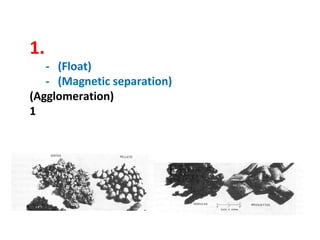

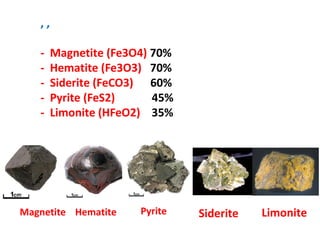

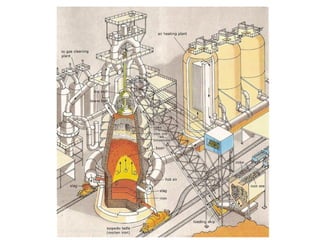

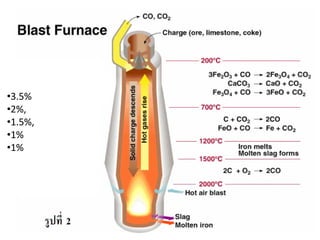

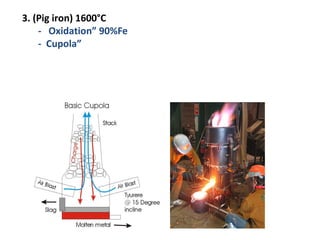

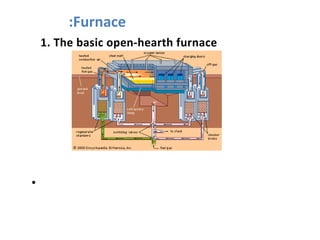

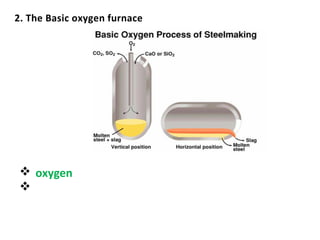

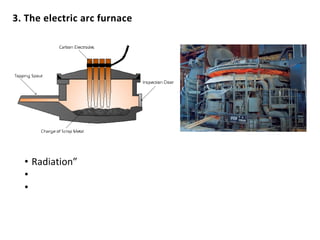

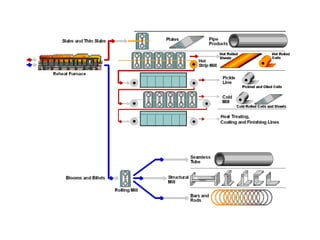

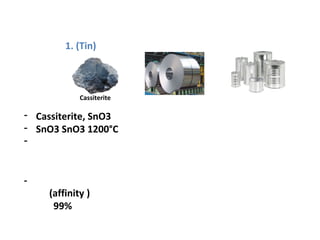

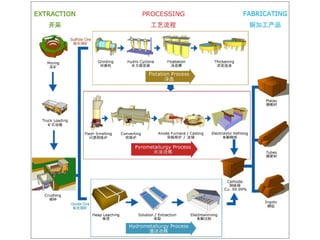

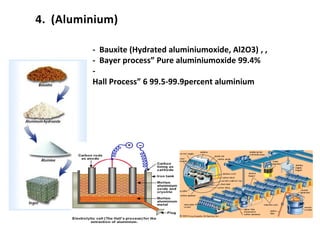

This document discusses engineering metallurgy and metal extraction processes. It describes five important metals - tin, lead, copper, aluminum, and magnesium - and their main ore sources. For each metal, it outlines the key extraction steps, including physical separation, smelting, and refining processes to purify the final product. Common furnace types used in metallurgy like basic open-hearth, basic oxygen, and electric arc furnaces are also introduced.