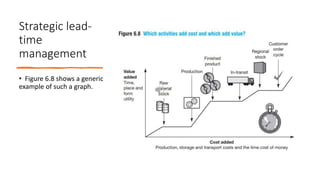

This document discusses strategic lead-time management. It argues that reducing lead times provides both cost and customer service benefits. Long lead times require more inventory and less responsiveness. The document outlines various pressures that have increased the importance of time-based competition, such as shortening product life cycles and customers' drive for reduced inventories. It discusses concepts like order-to-delivery cycle, cash-to-cash cycle, and the benefits of logistics pipeline management and reducing non-value adding time to compress lead times.