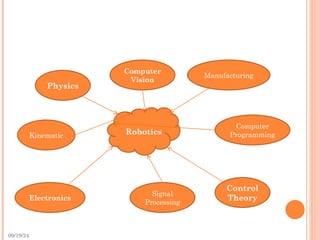

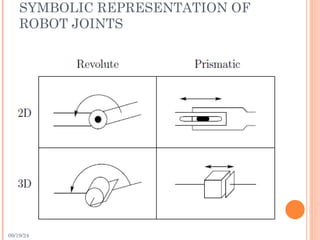

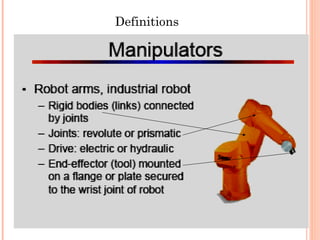

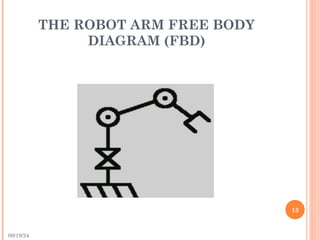

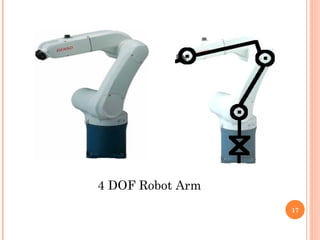

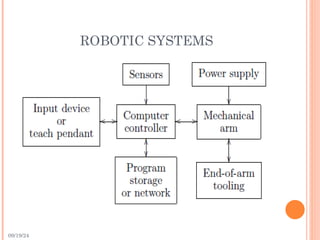

The document is a lecture on robotics, covering definitions, concepts, robotic systems, and manipulator classification. It explains the significance of the term 'robot', outlines applications, and describes the symbolic representation of robotic joints and degrees of freedom. Additionally, it discusses the power source, control methods, and geometric classifications of robotic manipulators.