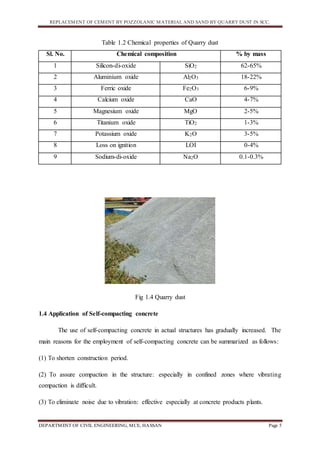

Self-compacting concrete (SCC) was developed in Japan to flow through reinforced structures without vibration or segregation. SCC offers benefits like improved productivity and work environment. However, high cement content increases costs and emissions. This study examines partially replacing cement with sugarcane bagasse ash, an industrial waste, and replacing sand with quarry dust. Sugarcane bagasse ash and quarry dust have pozzolanic properties and can improve concrete quality while reducing costs and waste. India produces large amounts of bagasse ash annually from its sugar industry. Using these waste materials in concrete could promote more sustainable construction practices.