This document provides source code for a simulation block called Reactor that models a reactor process for a training course on PCS 7. The block contains input and output variables to control filling valves, a mixer motor, and monitor temperature and level values. The code defines the block attributes, declares the input, in-out, and output variables, and contains the algorithm to simulate the reactor process over time based on the input conditions and parameter values provided.

![Training Center

for Automation and Drives

SIMATIC PCS 7 System Training

Blocks with SCLPage 5

Date: 09.01.2007

File: ST-PCS7SYS_V70_scl.5

SIMATIC PCS 7

Siemens AG, 2003. All rights reserved.

SITRAIN Training for

Automation and Drives

Menu Insert

-> Block Template

OB

FB

FC

Comment

Constant

Parameters

DB

Instance DB

DB Referencing UDT

UDT

-> Control Structure

IF

CASE

FOR

WHILE

REPEAT

***** OB *****

ORGANIZATION_BLOCK OBxxx

VAR_TEMP

// Reserved

Info: ARRAY[0..19] OF BYTE;

// Temporary Variables

END_VAR

BEGIN

// Statements

;

END_ORGANIZATION_BLOCK

***** FB *****

FUNCTION_BLOCK FBxxx

VAR_TEMP

// Temporary Variables

END_VAR

VAR

// Static Variables

END_VAR

BEGIN

// Statement part

;

END_FUNCTION_BLOCK

***** FC *****

FUNCTION FCxxx : INT

VAR_TEMP

// Temporary Variables

END_VAR

BEGIN

// Statement part

;

FCxxx := 100;

END_FUNCTION](https://image.slidesharecdn.com/ch7v70sclen-140422145011-phpapp02/85/Ch7-v70-scl_en-5-320.jpg)

![Training Center

for Automation and Drives

SIMATIC PCS 7 System Training

Blocks with SCLPage 11

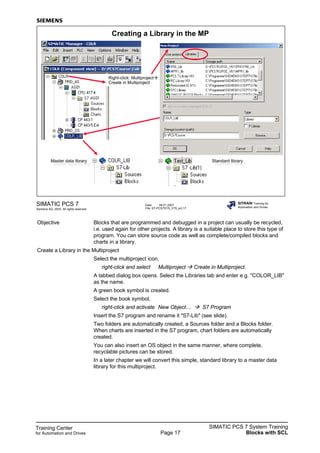

FUNCTION_BLOCK Reactor

(* Simulation block with feedback signals

for PCS 7 course only *)

(* Block Attributes *)

TITLE ='REAC';

VERSION:'5.0';

//KNOW_HOW_PROTECT if no comment

AUTHOR:Siemens;

FAMILY:Training;

NAME:PLANT;

(* Variable Declaration *)

VAR_IN_OUT

V1_OP_CL: BOOL; //Filling1

V2_OP_CL: BOOL; //Filling2

V3_OP_CL: BOOL; //Filling3

M1_ON_OF: BOOL; //Mixer motor

RS_COOL : BOOL; //Container empty and cold

SET_HOT : BOOL; //Container full and warm

V_RESET : BOOL; //Valves closed, motor off

END_VAR

VAR_INPUT

V1_FLOW: REAL := 100.0; //Flow V1 0..100%

V2_FLOW: REAL := 100.0; //Flow V2

V3_FLOW: REAL := 100.0; //Flow V3

CFV: REAL := 0.002; //Correction factor valves

V_HOT_FL: REAL := 0.0; //Flow heating 0..100%

TMP_ENV: REAL := 20.0; //Environment temperature

TMP_HOT: REAL := 120.0; //Heating medium temperature

T_LAG_SH: REAL := 10.0; //T_PT1-Shell[s]

T_LAG_IN: REAL := 30.0; //T_PT2-Inside[s] full reactor

SAMPLE_T: REAL := 1.0; //Sampling time[s]

END_VAR

Simulation block

REACTOR (FB600)](https://image.slidesharecdn.com/ch7v70sclen-140422145011-phpapp02/85/Ch7-v70-scl_en-11-320.jpg)