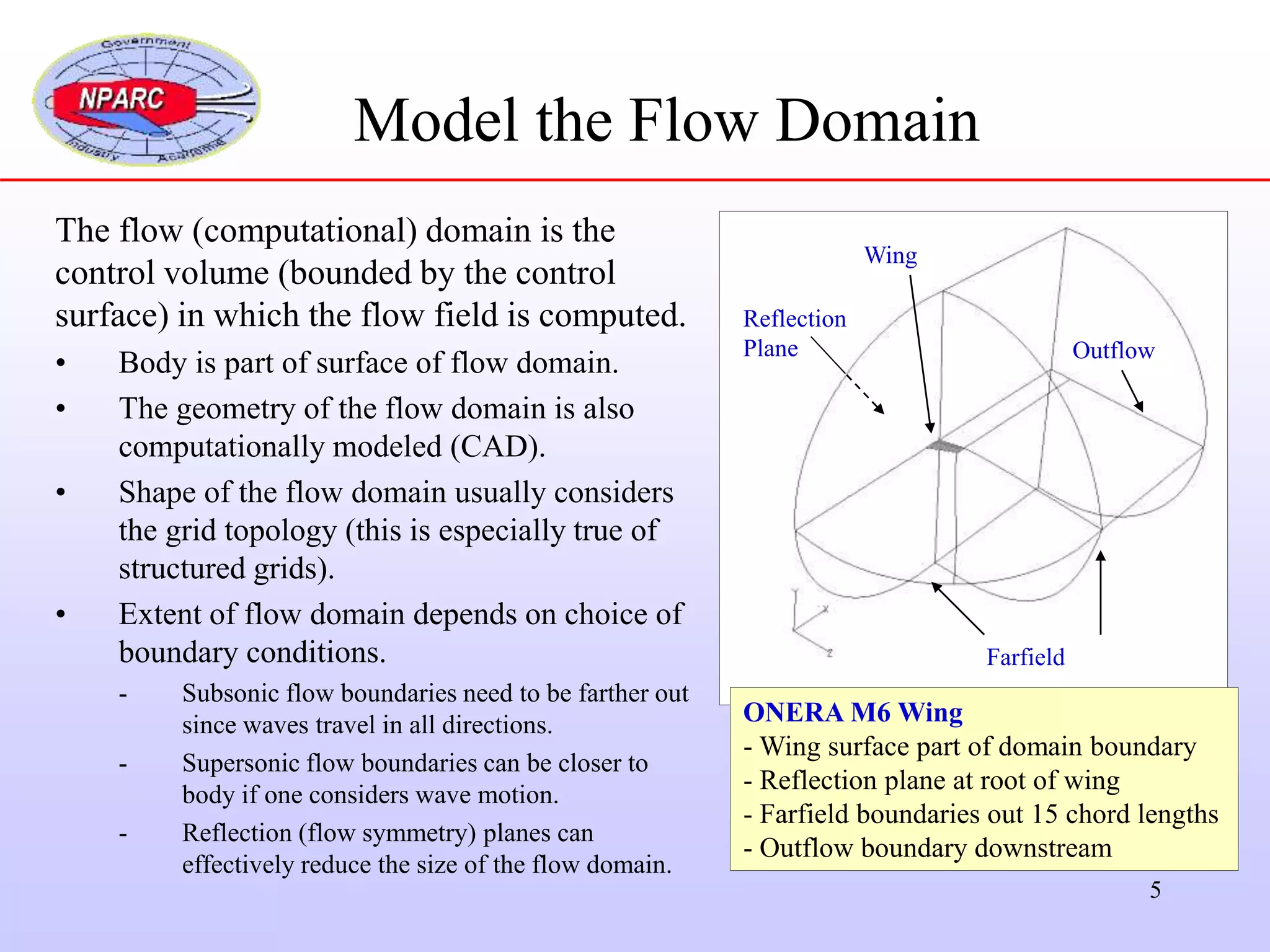

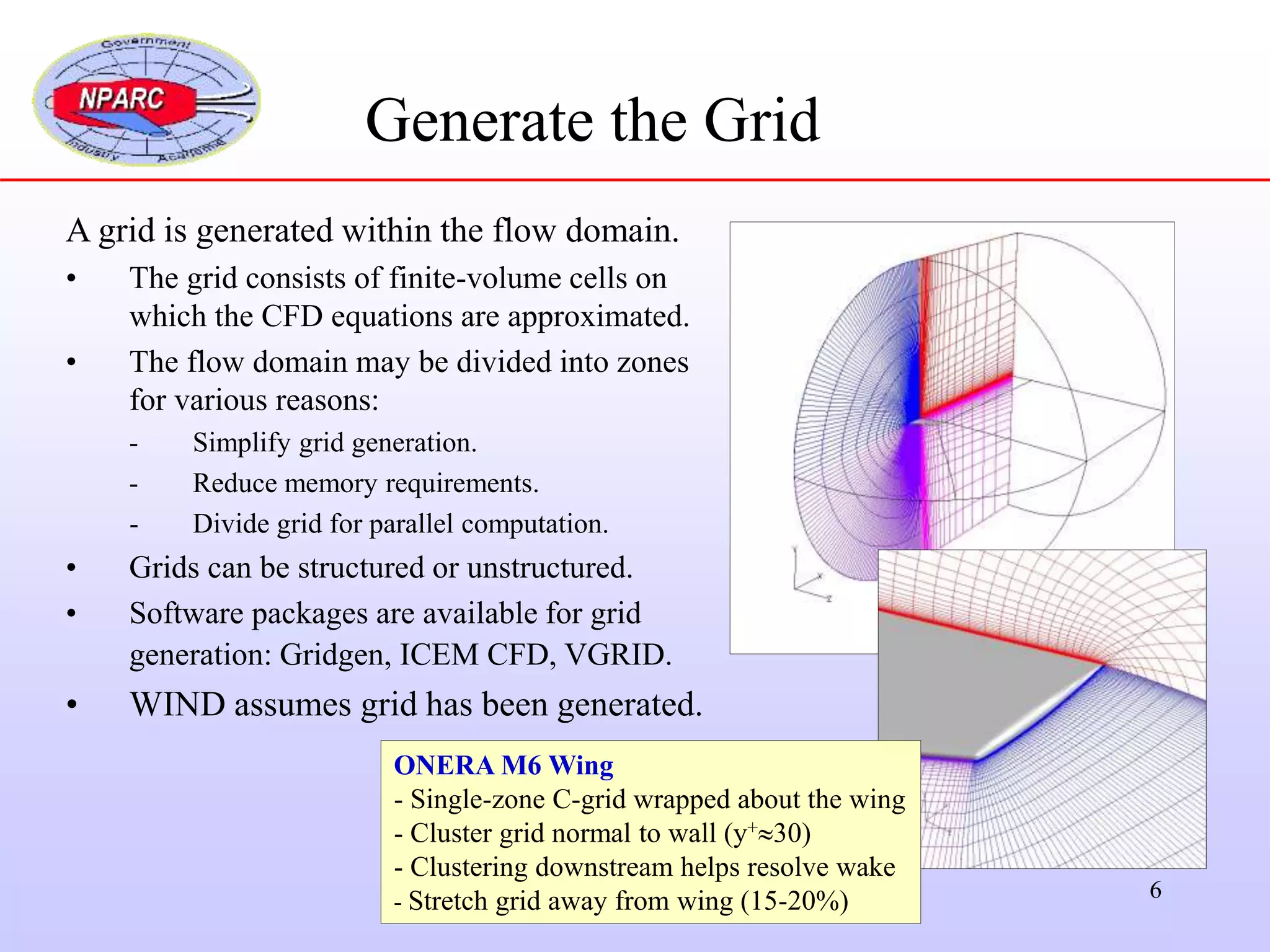

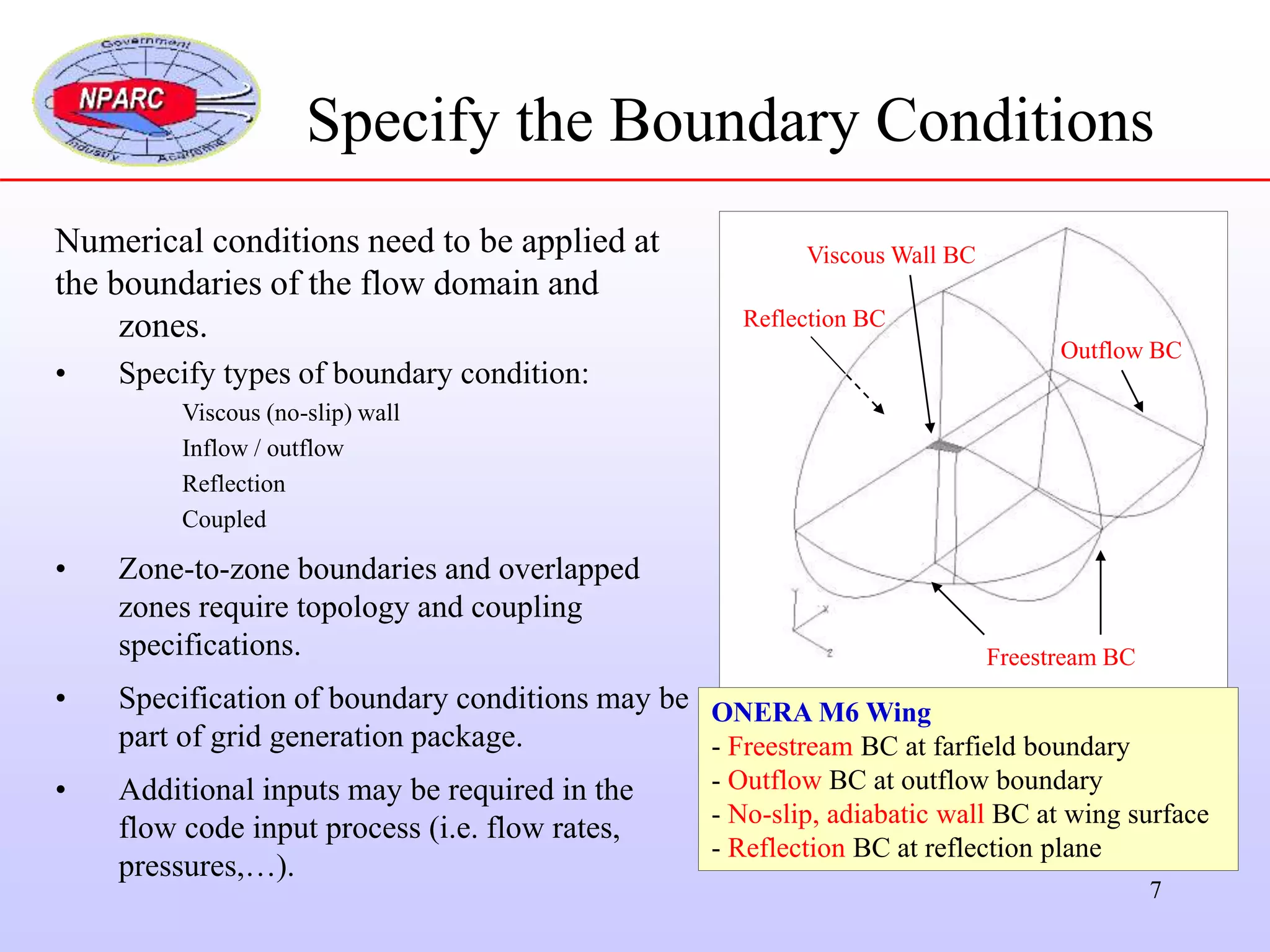

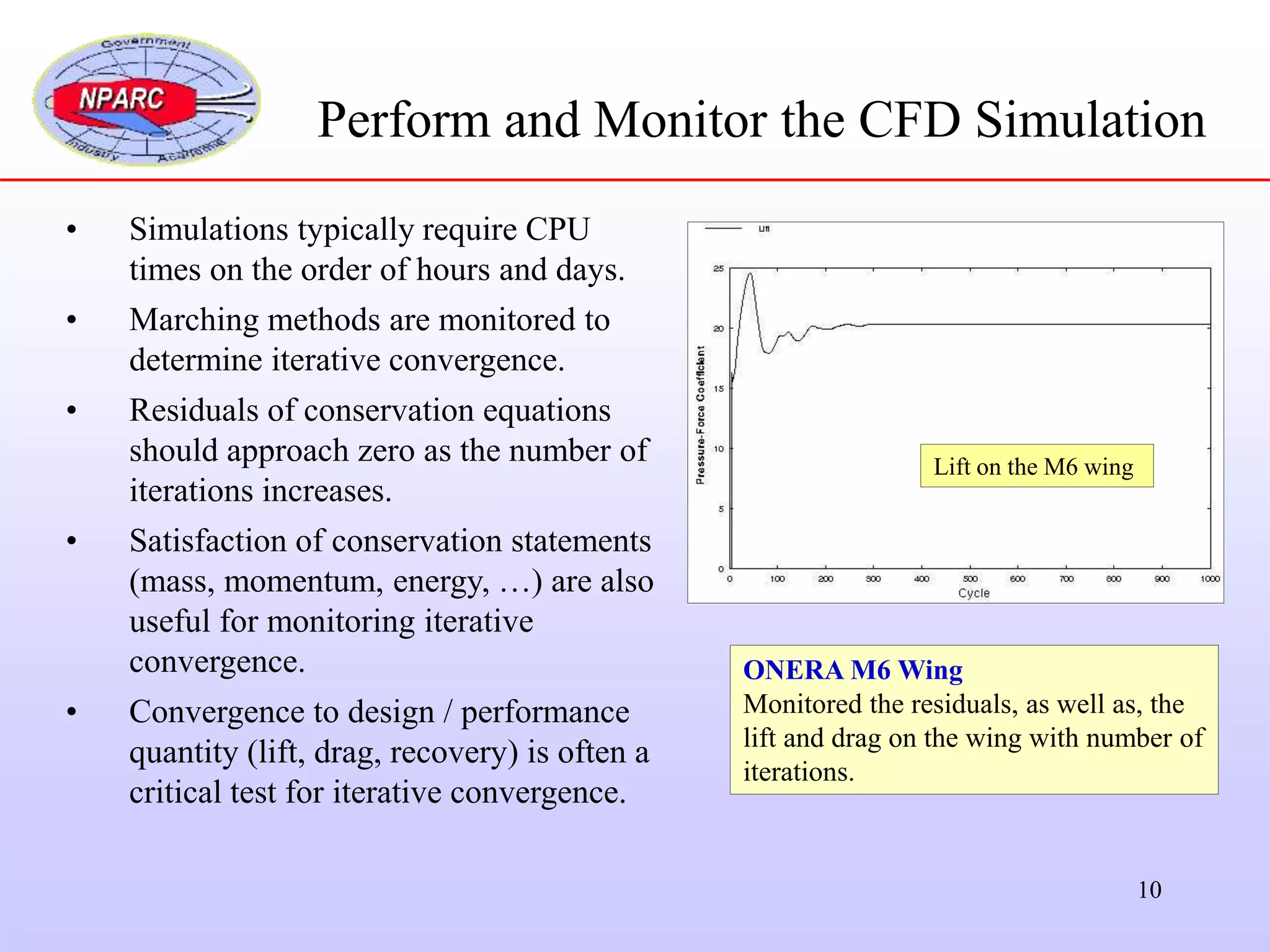

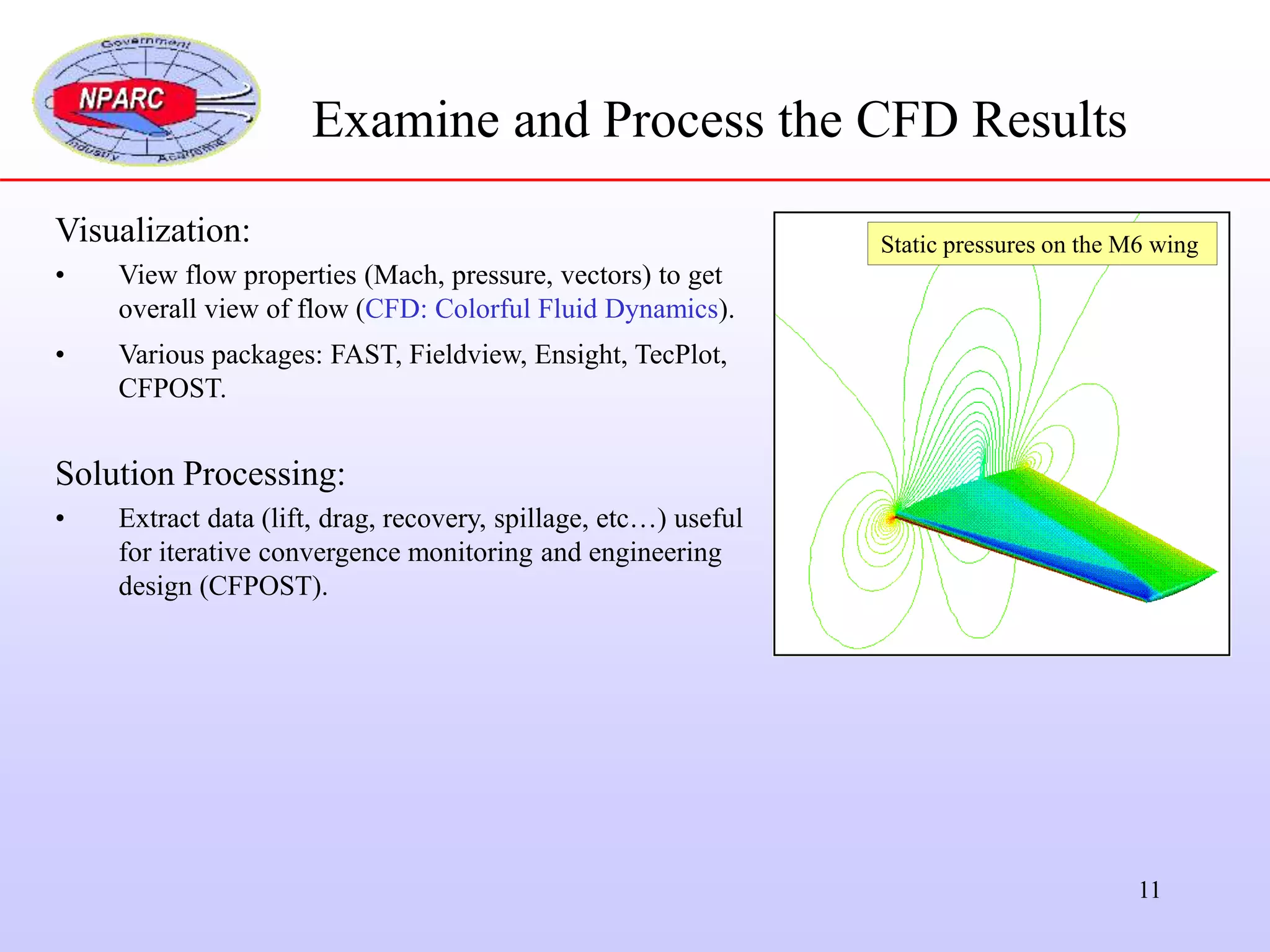

The CFD analysis process involves 11 steps: 1) formulating the flow problem, 2) modeling the geometry, 3) modeling the computational domain, 4) generating the grid, 5) specifying boundary conditions, 6) specifying initial conditions, 7) setting up the CFD simulation, 8) performing and monitoring the simulation, 9) examining and processing results, 10) further analysis if needed, and 11) reporting findings. The objective is to obtain accurate, credible and useful results with confidence in the CFD simulation.