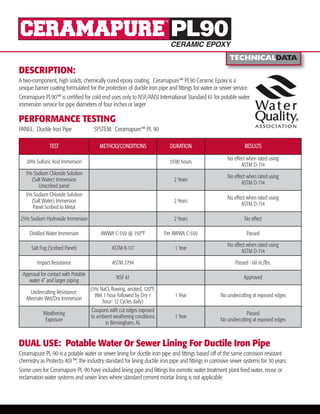

Ceramapure PL90 is a two-component, high solids epoxy coating formulated for protecting ductile iron pipe and fittings used in water and sewer systems. It provides corrosion resistance in acid, salt, and alkaline conditions as shown through various performance tests. Ceramapure PL90 is certified for use in potable water systems for pipe diameters 4 inches or larger, and can be used to line pipe and fittings for applications like osmotic water treatment plants, reuse/reclamation water, and sewer lines where cement mortar lining cannot be used.