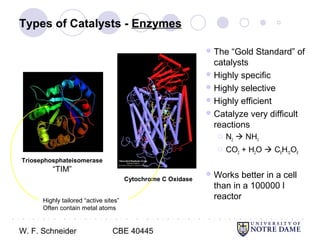

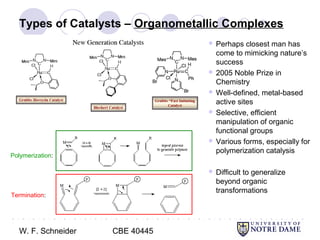

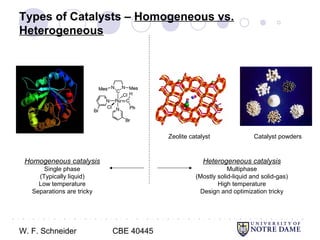

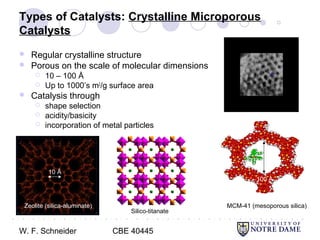

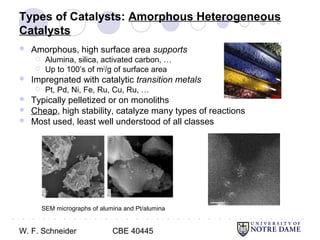

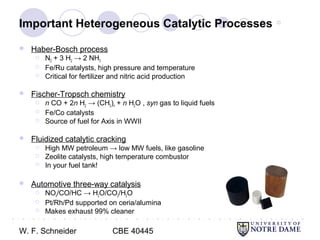

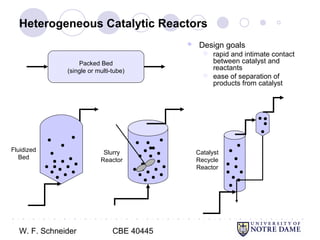

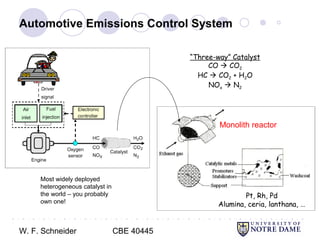

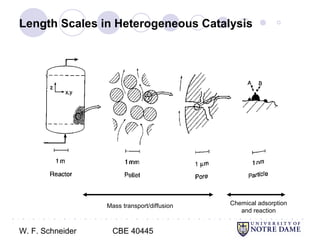

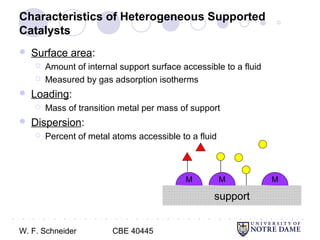

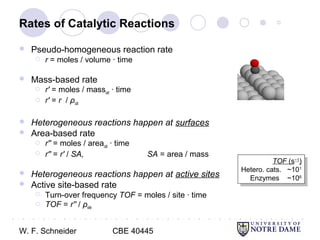

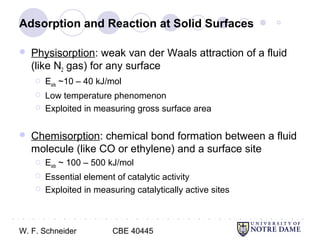

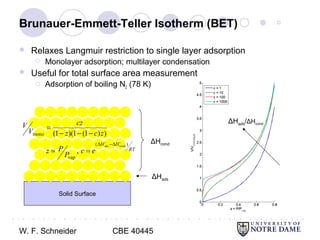

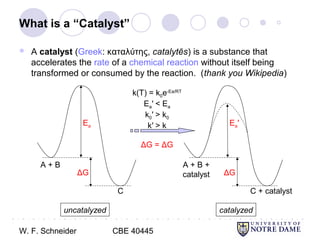

This document provides an introduction to catalysis. It defines a catalyst as a substance that accelerates a chemical reaction without being consumed. It describes how catalysts lower the activation energy of reactions, allowing them to proceed more quickly. It discusses different types of catalysts including enzymes, organometallic complexes, zeolites, and metals supported on high surface area materials. It also describes important industrial catalytic processes and considerations in heterogeneous catalysis such as reactor design, mass transport limitations, and the characterization of catalysts.

![W. F. Schneider CBE 40445

● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ●

○

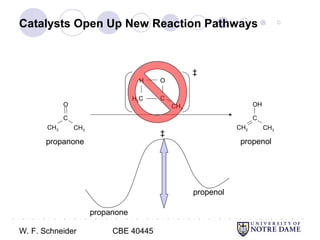

Catalysts Open Up New Reaction Pathways

CH3

C

CH3

O

CH2

C

CH3

OH

propanone propenol

OH−

CH2

C

CH3

O−

+ H2O

−OH−

Base catalyzed

propanone

propenol

intermediate

‡ ‡

rate = k[OH−

][acetone]](https://image.slidesharecdn.com/catalysis-180724171149/85/Catalysis-4-320.jpg)

![W. F. Schneider CBE 40445

● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ● ○ ●

○

Catalysts Open Up New Reaction Pathways

CH3

C

CH3

O

CH2

C

CH3

OH

propanone

propenol

+ H2O

Acid catalyzed

H3O+

CH3

C

CH3

OH

+

−H3O+

propenol

different

intermediate

‡ ‡

propanone

rate = k[H3O+

][acetone]](https://image.slidesharecdn.com/catalysis-180724171149/85/Catalysis-5-320.jpg)