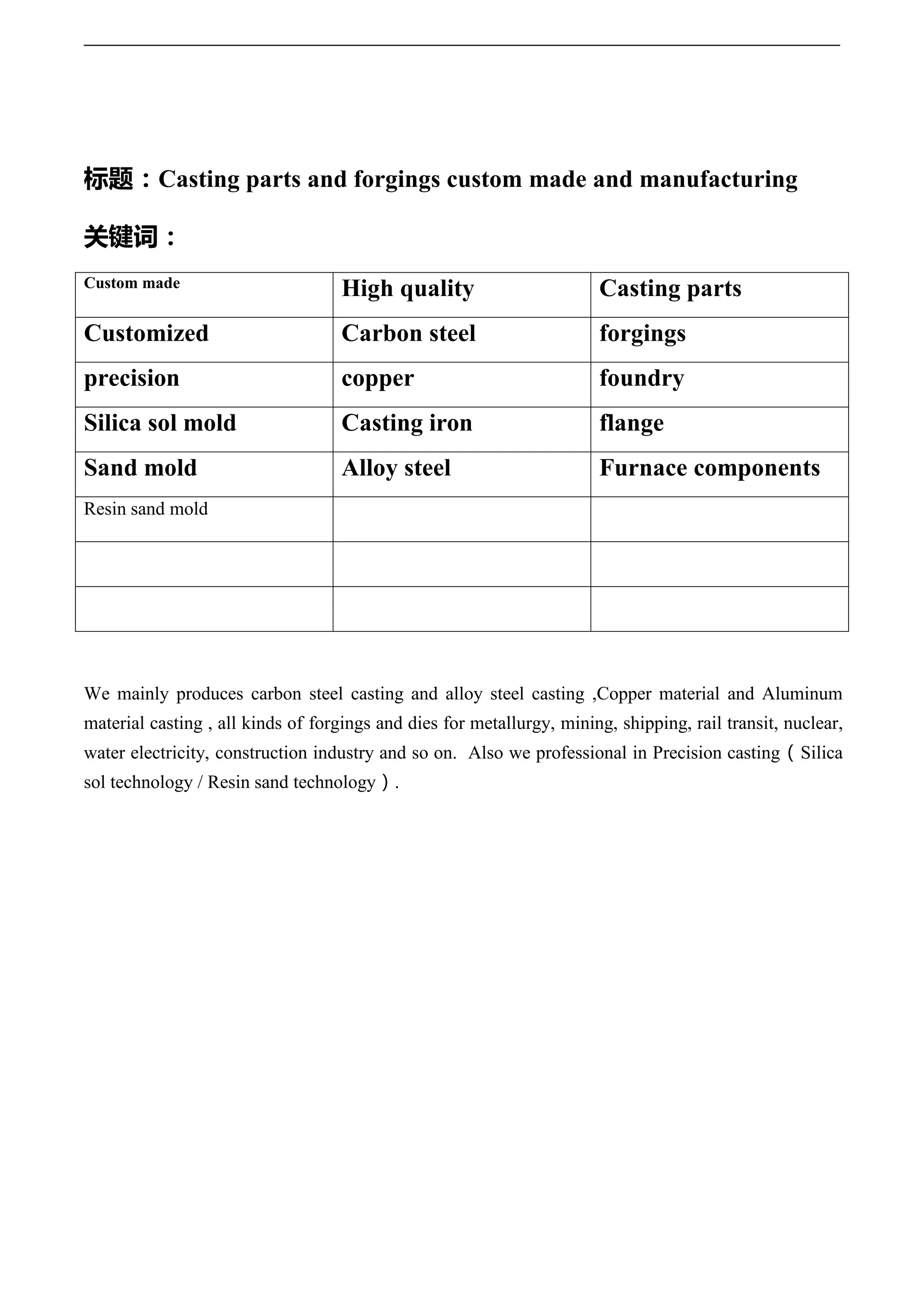

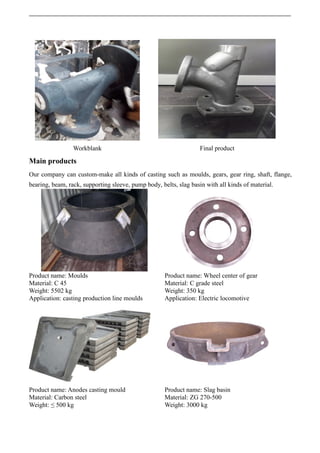

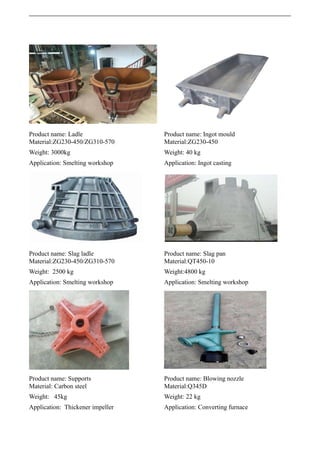

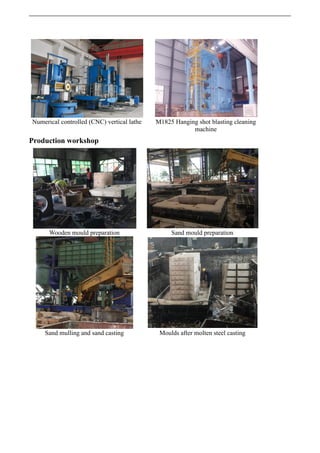

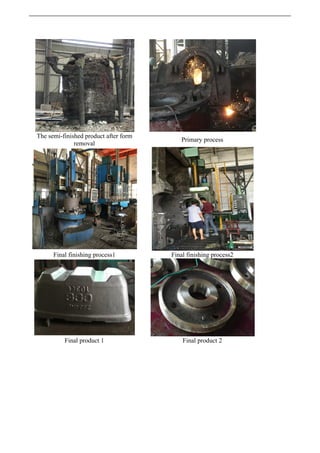

Our company specializes in custom-made castings and forgings using various materials like carbon steel, alloy steel, copper, and aluminum. We produce parts for industries like metallurgy, mining, shipping, and construction. We have advanced equipment and facilities for casting, heat treatment, machining, and quality testing to ensure high precision and quality according to customer requirements and standards.