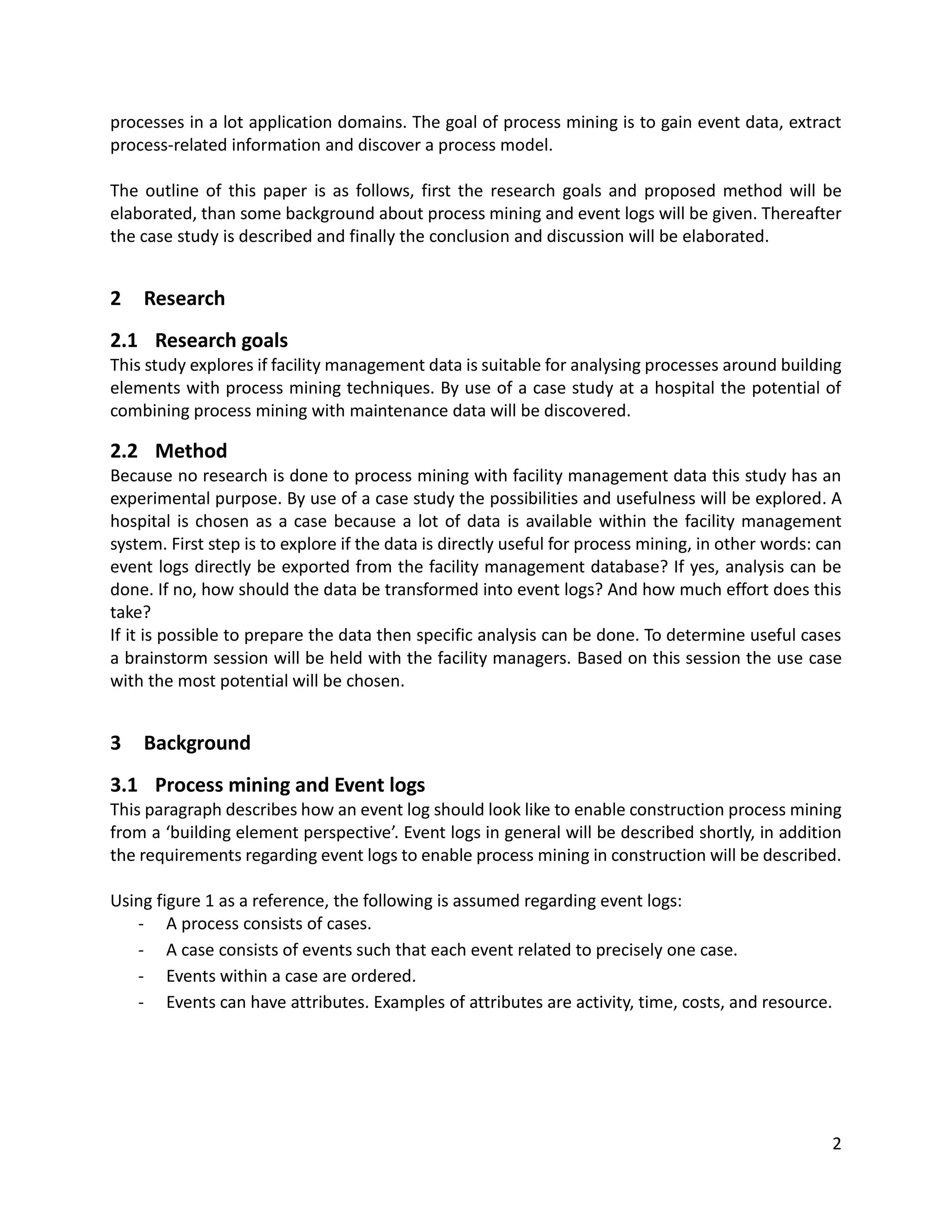

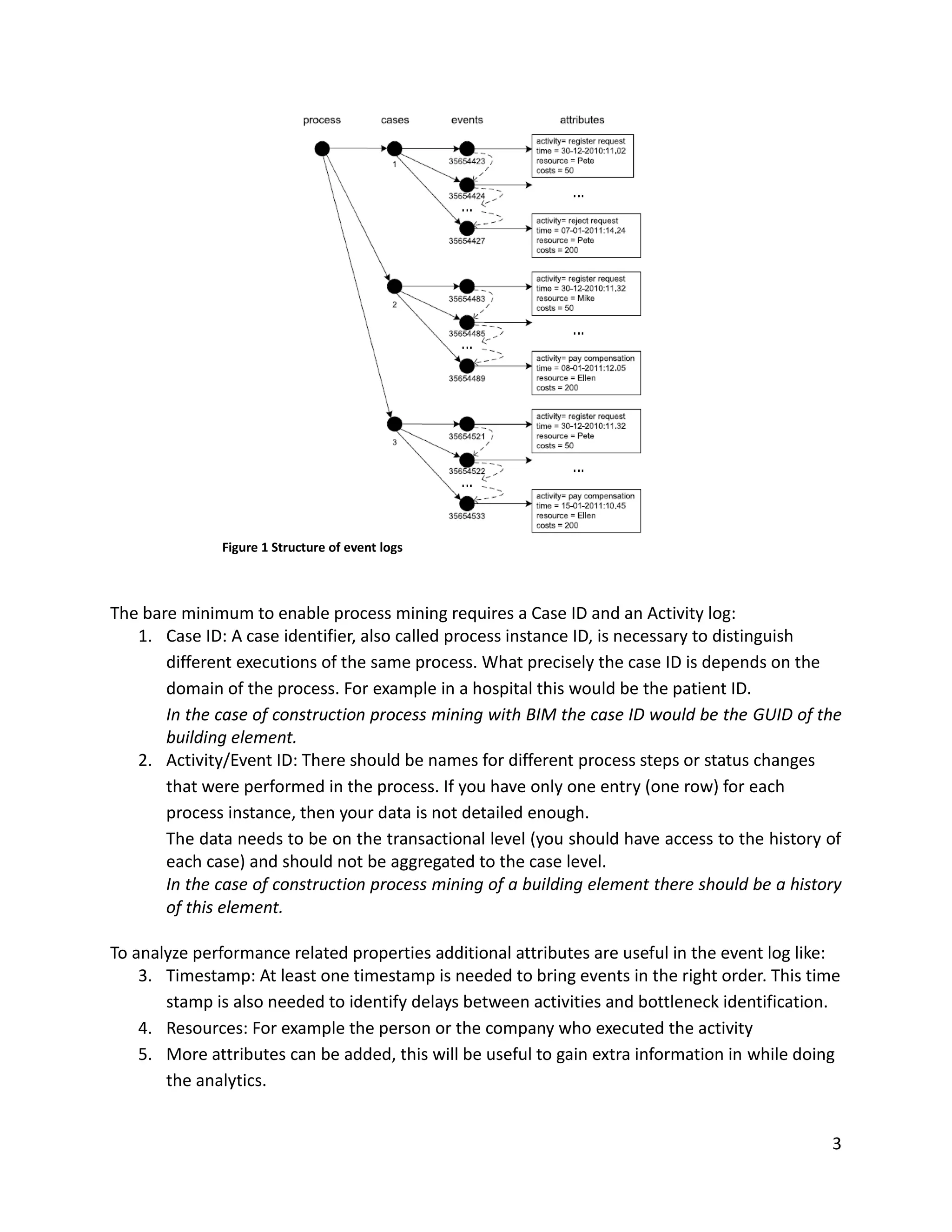

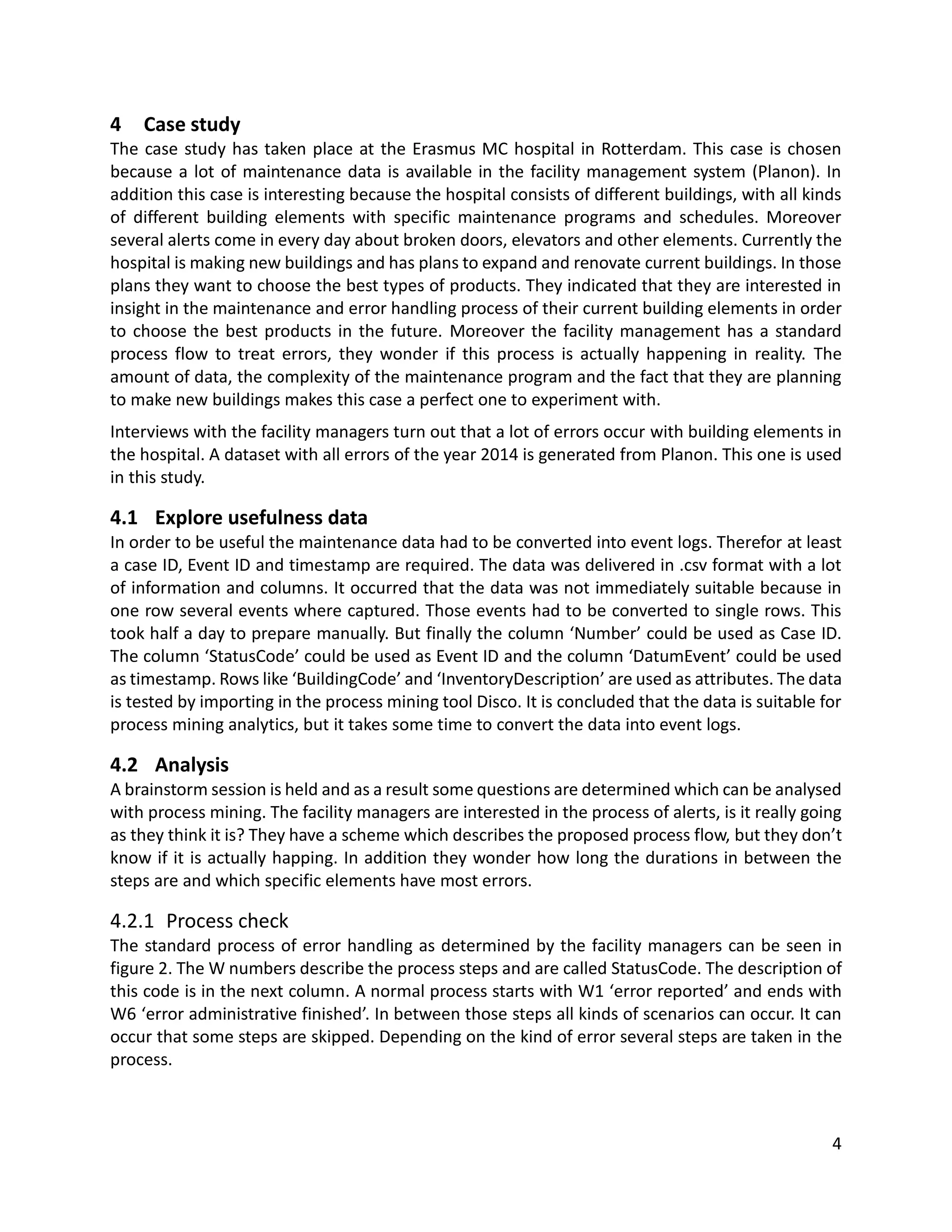

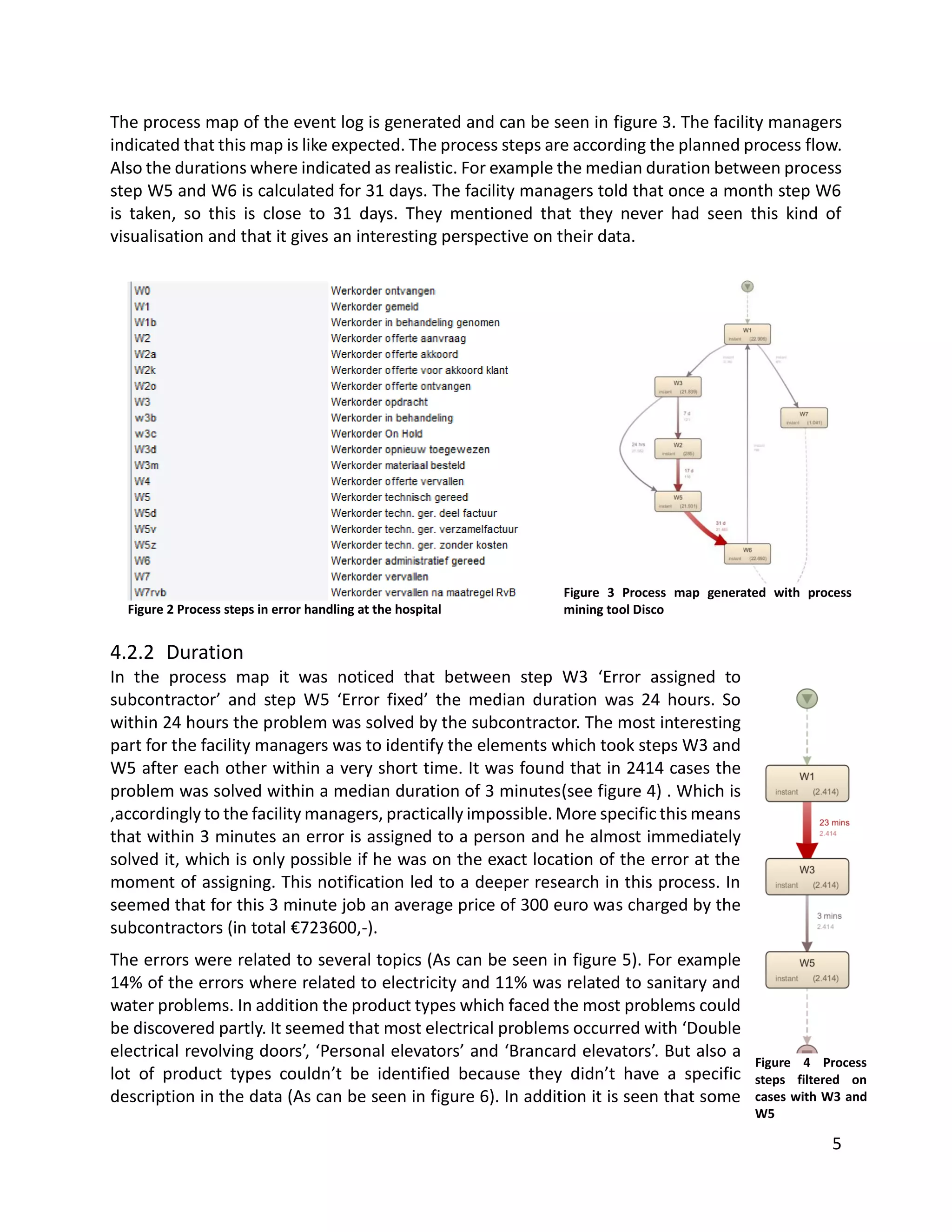

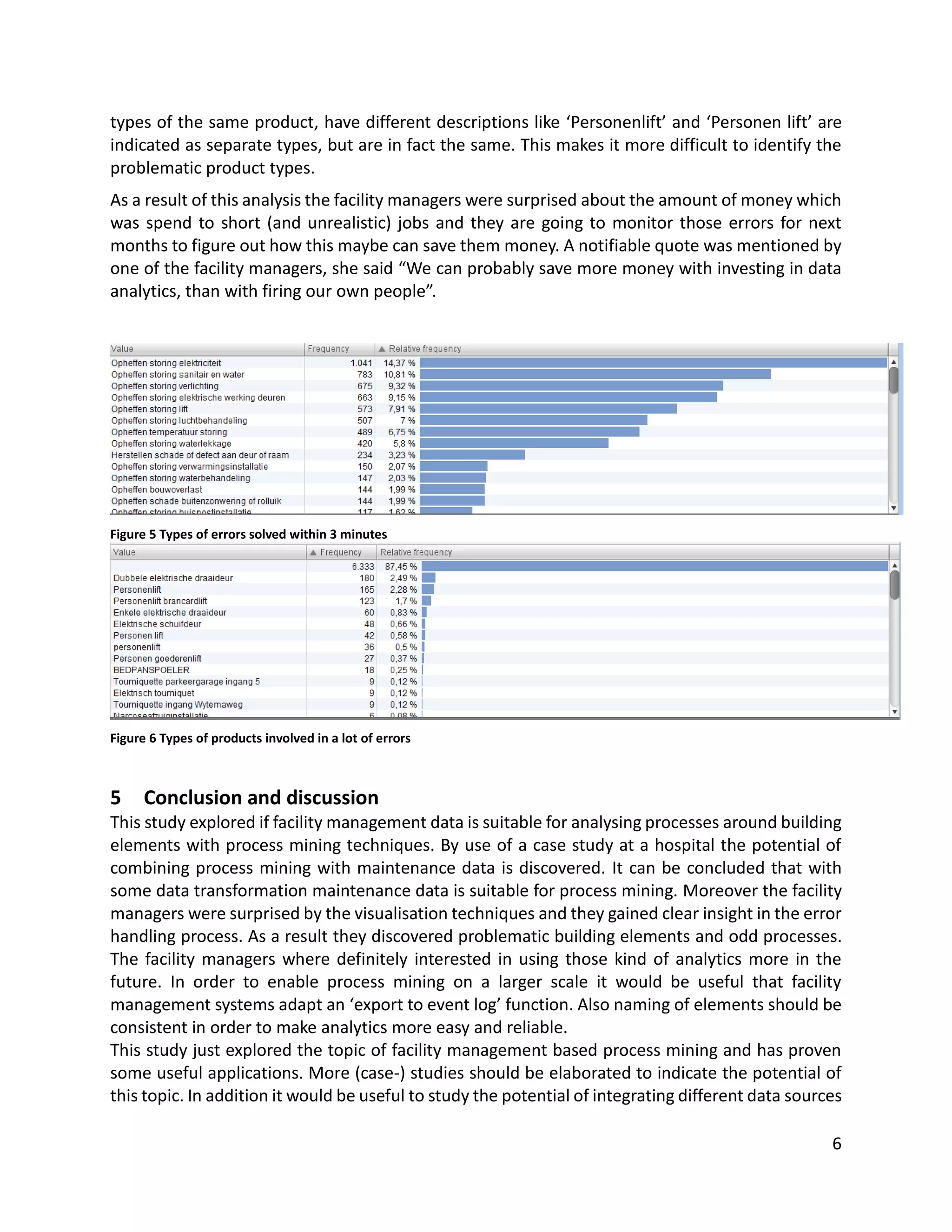

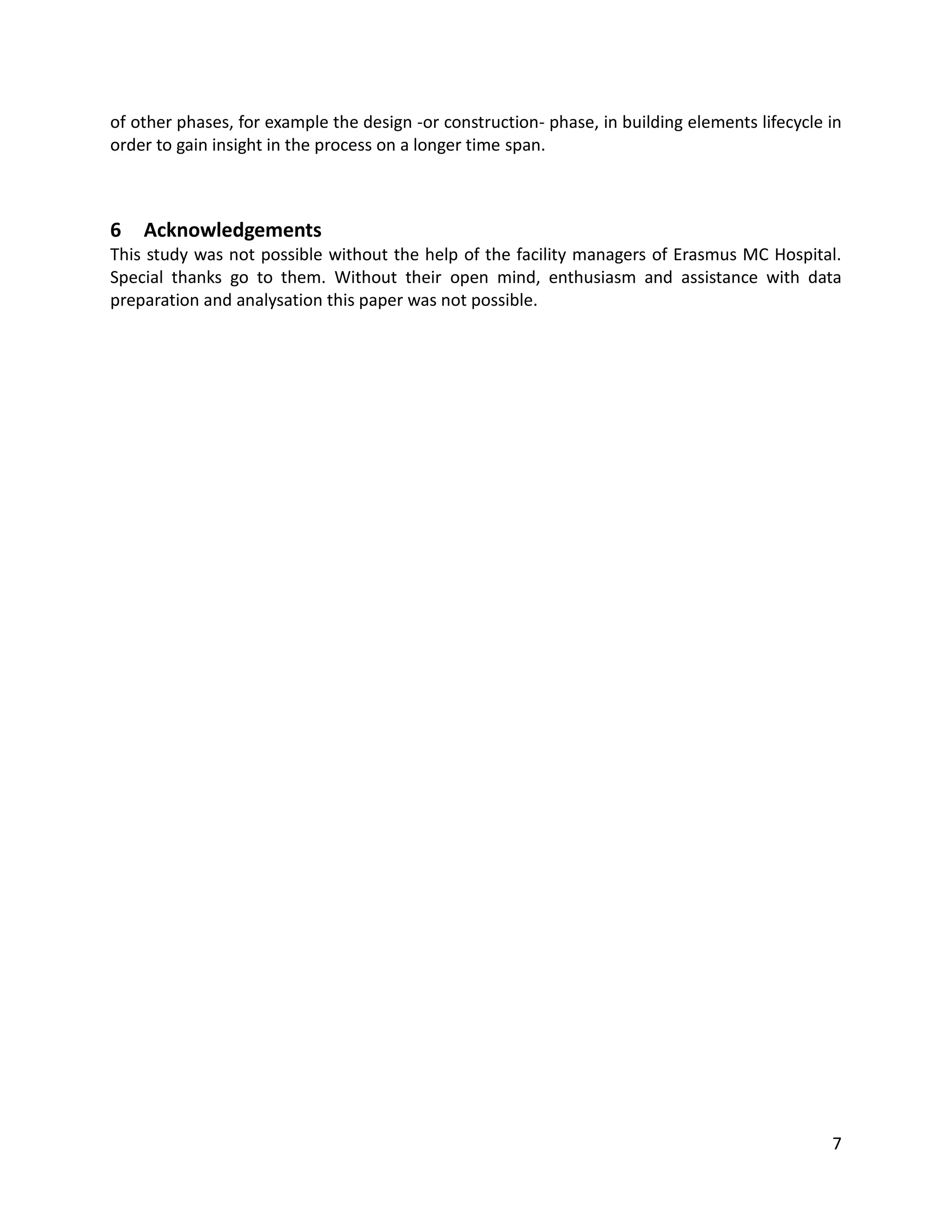

The study explores the use of process mining techniques on facility management data, specifically focusing on maintenance error data from a hospital. It concludes that with appropriate data transformation, this maintenance data is suitable for analysis, allowing facility managers to gain insights into error handling processes and discover problematic building elements. The findings suggest that improved data analytics could lead to cost savings and better management practices in facility operations.