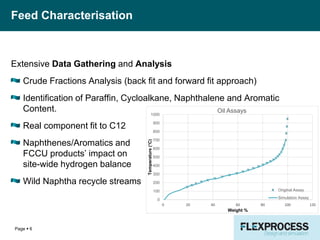

This document summarizes a case study where a process engineering consultancy created detailed steady state process simulation models of key units at a refinery client's site. The models were built using plant data and drawings to optimize operations, support projects, and identify bottlenecks. Extensive feed characterization and testing ensured the models accurately matched plant data. The accurate, integrated models allow the client to use them for scheduling, operations, projects, and process safety while saving significant time over alternative approaches.