The document describes setting up and simulating an atmospheric crude distillation column in HYSYS. It involves characterizing the crude oil feed using assay data, installing a pre-fractionation train with a separator, heater and mixer to determine the feed to the column, and then installing the column along with defining steam and energy streams. The column is configured as a 29 stage ideal column with overhead, bottoms and side product draws using a built-in 3 stripper crude column template.

![Atmospheric Crude Tower R1-9

R1-9

R1.3.1 Simulate the Pre-

Fractionation Train

Inlet Stream

Specify the Inlet stream (Raw Crude) as shown below.

Because the composition has been transferred from the Oil

Characterization, the stream is automatically flashed.

Pre-Flash Operations

Install the Separator, Heater, and Mixer and provide the

information displayed below:

Stream [Raw Crude]

In this cell... Enter...

Temperature [F] 450.0°F

Pressure [psia] 75.0 psia

Std Ideal Liq Vol Flow [barrel/day] 100,000 barrel/day

Separator [PreFlash]

Tab [Page] In this cell... Enter...

Design

[Connections]

Inlet Raw Crude

Vapour Outlet PreFlash Vap

Liquid Outlet PreFlash Liq

Heater [Crude Heater]

Tab [Page] In this cell... Enter...

Design

[Connections]

Inlet PreFlash Liq

Outlet Hot Crude

Energy Crude Duty

Design [Parameters] Delta P 10.00 psi

Worksheet

[Conditions]

Temperature (Hot Crude) 650 °F](https://image.slidesharecdn.com/atmosphericcrudetower-180803121950/85/Atmospheric-crude-tower-simulation-9-320.jpg)

![R1-10 Steady State Simulation

R1-10

The calculated specifications for the Pre-Fractionation Atm Feed

stream appear below.

The Pre-Fractionation train is shown as follows:

Mixer [Mixer]

Tab [Page] In this cell... Enter...

Design

[Connections]

Inlets Hot Crude, PreFlash Vap

Outlet Atm Feed

Figure R1.7

Figure R1.8](https://image.slidesharecdn.com/atmosphericcrudetower-180803121950/85/Atmospheric-crude-tower-simulation-10-320.jpg)

![Atmospheric Crude Tower R1-11

R1-11

R1.3.2 Install Atmospheric

Crude Fractionator

Steamand TrimDuty Streams

Before simulating the atmospheric crude tower, the steam feeds

and the energy stream (Q-Trim - representing the side

exchanger on stage 28) to the column must be defined.

The Q-Trim stream does not require any specifications, this will

be calculated by the Column.

Three steam streams are fed to various locations in the tower.

Specify the steam streams as shown below. Define the

composition for each as H2O = 1.0000.

These streams could be installed inside the Column Build

Environment as well. By taking this approach, you will need

to “attach” these streams to the Column Flowsheet so that

they can be used in the calculations.

Column

In this application, the Input Experts option have been turned

off, and the Column is being configured directly through the

Column property view.

An energy stream can be installed by selecting the

appropriate icon from the palette, or a material stream

converted to an energy stream on the Util page of the stream

property view.

Stream Name Temperature [F] Pressure [psia] Mass Flow [lb/hr]

Main Steam 375.00 150.00 7500.00

Diesel Steam 300.00 50.00 3000.00

AGO Steam 300.00 50.00 2500.00](https://image.slidesharecdn.com/atmosphericcrudetower-180803121950/85/Atmospheric-crude-tower-simulation-11-320.jpg)

![R1-14 Steady State Simulation

R1-14

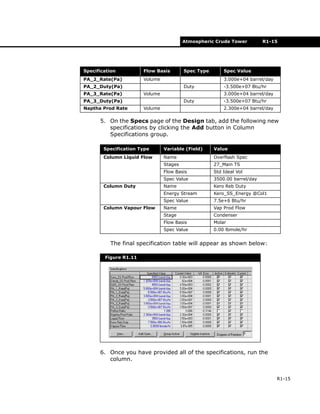

6. In the Atmos Tower Column property view, specify the

column information below.

Field units are used for column preferences.

Specifications

On the Monitor page of the Design tab, make the following

changes and input the values into the default set of

specifications supplied with the pre-built 3-Side Stripper

Column.

1. Change all the Pump Around delta T specifications to a

Duty specification.

2. Delete the Kero SS BoilUp Ratio and the Residue Rate

specs.

Open the specification property view by clicking the View

button, then click Delete to delete the specification.

3. Specify the Reflux Ratio spec to have a value of 1. Clear

the Reflux Ratio Active checkbox and make it an Estimate

only.

4. Change the following default specifications by selecting the

specification in the table and clicking the View button.

Change the Flow Basis to Std Ideal Volume before entering

values.

Column [Atms Tower]

Tab [Page] In this cell... Enter...

Parameters

[Profiles]

Condenser Pressure 19.7 psia

29_Main TS Pressure 32.7 psia

Condenser Temperature 100°F

1_Main TS Temperature 250°F

29_Main TS Temperature 600°F

Specification Flow Basis Spec Type Spec Value

Kero_SS Prod Flow Volume 9300 barrel/day

Diesel_SS Prod Flow Volume 1.925e+04 barrel/day

AGO_SS Prod Flow Volume 4500 barrel/day

PA_1_Rate(Pa) Volume 5.000e+04 barrel/day

PA_1_Duty(Pa) Duty -5.500e+07 Btu/hr](https://image.slidesharecdn.com/atmosphericcrudetower-180803121950/85/Atmospheric-crude-tower-simulation-14-320.jpg)

![R1-16 Results

R1-16

R1.4 Results

Workbook Case (Main)

The material stream results for the Workbook Case[Main]

appear below.

Figure R1.12](https://image.slidesharecdn.com/atmosphericcrudetower-180803121950/85/Atmospheric-crude-tower-simulation-16-320.jpg)

![Atmospheric Crude Tower R1-17

R1-17

Workbook Case (Atms Tower)

The material stream results for the Workbook Case [Atms

Tower] appear below.

Figure R1.13](https://image.slidesharecdn.com/atmosphericcrudetower-180803121950/85/Atmospheric-crude-tower-simulation-17-320.jpg)