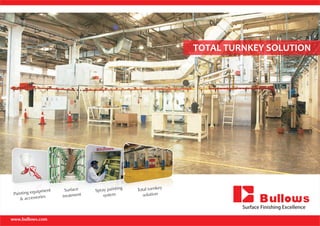

Bullows Paint Equipment Pvt. Ltd. offers total turnkey solutions for spray painting and surface treatment, providing a wide range of painting equipment and accessories backed by over 45 years of industry experience. The company aims to enhance customer processes through innovative technologies and compliance with quality standards, establishing long-term relationships with clients. Additionally, it specializes in automated and customized painting systems, along with support services such as maintenance contracts and onsite training.