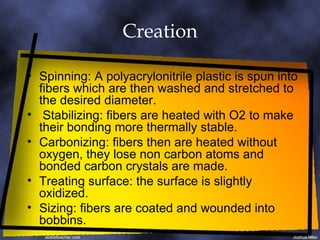

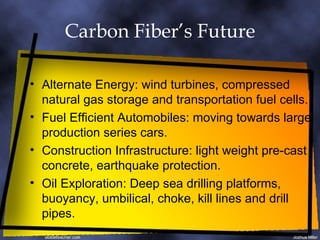

Carbon fiber is a thin strand composed mainly of carbon atoms that was first created by Dr. Roger Bacon. It has the highest compressive strength and heat tolerance of reinforcing materials, along with a low density and coefficient of thermal expansion. Carbon fiber is used to reinforce composites, in high-temperature structural applications, and as electrodes for its corrosion resistance and surface area.