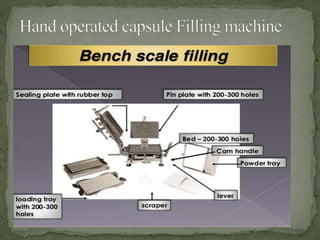

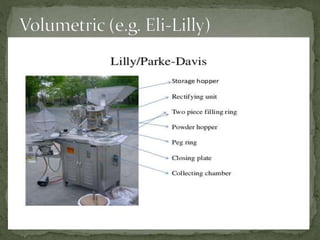

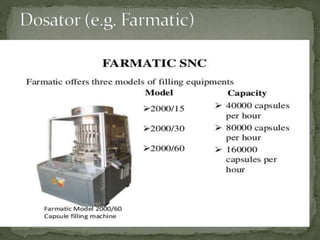

This document describes a capsule filling machine. It has several components: a bed and loading tray with 200-300 holes, a powder tray, a pin plate, a lever, cam handle, sealing plate with rubber top, and scraper. The machine is widely used in the pharmaceutical industry. It can fill 6000 capsules per hour and is made of stainless steel. All operations are manual. It uses a volumetric filling method where powder is filled to the upper surface of a body containing ring. Major manufacturers of these machines include Eli Lilly, Park-Davis, and Farmatic.