Capacity Planning Chapter outline 12.1 Facilities deci.docx

- 1. Capacity Planning Chapter outline 12.1 Facilities decisions 12.2 Facilities strategy 12.3 Sales and operations planning definition 12.4 Cross-functional nature of S&OP 12.5 Planning options 12.6 Basic aggregate planning strategies 12.7 Aggregate planning costs 12.8 Aggregate planning example 12.9 Key points and terms In this chapter, we discuss capacity decisions related to carrying out the produc- tion of goods and services. Firms make capacity planning decisions that are long range, medium range, and short range in nature. These decisions follow naturally from supply chain decisions that already have been made and forecasting infor- mation as an input.

- 2. Capacity decisions must be aligned with the operations strategy of a firm. The operations strategy provides a road map that is used in making supply chain deci- sions to create a network of organizations whose work and output are used to satisfy customers' product and service needs. Capacity decisions are based on forecasted estimates of future demand. For example, operations and marketing collaborate to develop a forecast for demand for resort spa services before the re- sort makes capacity planning decisions regarding the appropriate facility and staff sizes for the spa. As was discussed in the previous chapter, long-range decisions are concerned with facilities and process selection, which typically extend about one or more years into the future. The first part of this chapter describes facilities decisions and a strategic approach to making them. In this chapter we also deal with medium- range aggregate planning, which extends from six months to a year or two into the future. The next chapter discusses short-range capacity decisions of less than six months regarding the scheduling of available resources to meet demand. Facilities, aggregate planning, and scheduling form a hierarchy of capacity deci- sions about the planning of operations extending from long, to medium, to short range in nature. First, facility planning decisions are long term

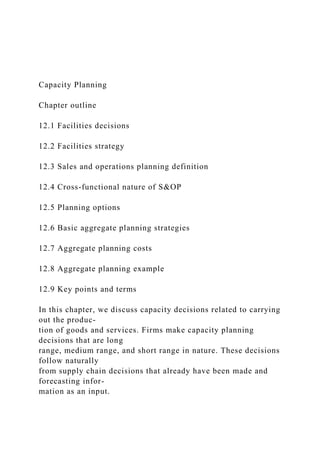

- 3. in nature, made to 285 286 Part Four Capacity and Scheduling FIGURE 12.1 Hierarchy of capacity decisions. 0 Scheduling .. 6 12 Months Planning Horizon 18 24 obtain physical capacity that must be planned, developed, and constructed bef011! its intended use. Then, aggregate planning determines the workforce level and p:ro-- duction output level for the medium term within the facility capacity available Finally, scheduling consists of short-term decisions that are constrained by aggregall! planning and allocates the available capacity by assigning it to specific activities. This hierarchy of capacity decisions is shown in Figure 12.1.

- 4. Notice that the deci- sions proceed from the top down and that there are feedback loops from the b~ tom up. Thus, scheduling decisions often indicate a need for revised aggrega~ planning, and aggregate planning also may uncover facility needs. We define capacity (sometimes referred to as peak capacity) as the maximum output that can be produced over a specific period of time, such as a day, week, or year. Capacity can be measured in terms of output measures such as number ot units produced, tons produced, and number of customers served over a sp ecified period. It also can be measured by physical asset availability, such as the number of hotel rooms available, or labor availability, for example, the labor available fO£ consulting or accounting services. Estimating capacity d ep ends on reasonable assumptions about facilities, equip- ment, and workforce availability for one, two, or three shifts as well as the operat- ing days per week or per year. If we assume two eight-hour shifts are available for five days per week all year, the capacity of a facility is 16 X 5 = 80 hours per week and 80 X 52 = 4160 hours per year. However, if the facility is staffed for only one shift, these capacity estimates must be halved. Facility capacity is not available un- less there is a workforce in place to operate it.

- 5. Utilization is the relationship between actual output and capacity and is de- fined by the following formula: Actual output Utilization = C . X 100% apaCity The utilization of capacity is a useful measure for estimating how busy a facility is or the proportion of total capacity being used . It is almost never reasonable to plan for 100 percent utilization since spare (slack) capacity is needed for planned and unplanned events. Planned events may include required maintenance or equipment replacement, and unpla1med events could be a late delivery from a supplier or unexpected demand. Chapter 12 Capacity Planning 287 - Operations Leader Bridge Collapse Illustrates Need for Emergency Capacity The I-35W Mississippi River bridge near downtown Mi nneapolis and the University of Minnesota col- lapsed during the evening rush hour on August 1, 2007. Seventy-five city, county, state, and federal agencies were involved in the rescue effort. Such cata- strophic events illustrate the necessity for capacity

- 6. availability in emergency services. The Minneapolis police and fire departments were among the first responders to the disaster, and while they generally have excess capacity, utilization of those services was temporarily pushed to the maxi- mum. Suburban police and fire units, with their own available capacity, were brought in to handle other demands for those services that were unre- lated to the bridge collapse. While a majority of injured victims were treated at Hennepin County Medical Center, nine other area hospitals also treated victims. Such collaboratio n among hospital emergency departments is necessary during large disasters as no single hospital has enough capacity to absorb these demand spikes. The excellent working relationships among agencies that had developed through joint train- ing, planning, and previous emergency incidents were cited as one of the primary reasons that re- sponse and recovery operations went smoothly. As one rescue leader commented, "We didn't view it as a Minneapolis incident; it was a city/county/state incident." Source: Adapted from information compiled from several sources, including "I-35W Mississippi River Bridge," www.wikipedia.org, 2009. Utilization rates vary widely by industry and firm. Continuous flow processes may have utilization near 100 percent. Facilities with assembly- line processes may

- 7. set planned utilization at 80 percent to allow for flexibility to meet unexpected demand. Batch and job shop processes generally have even lower utiliza tion. Emergency services such as police, fire, and emergency medical care often have fairly low utilization, in part so that they can meet the demands placed on them during catastrophic events. The Operations Leader box tells the story of the Inter- state 35W bridge collapse in Minneapolis, Minnesota, as an example of the need for capacity from a variety of organizations during emergencies. It is possible in the short term for a firm to operate above 100 percent utilization. Overtime or an increased work-flow rate can be used in the short term to meet highly variable or seasonal demand. Mail and package delivery services often use these means to increase work output before major h olidays . However, firms cannot sustain this rapid rate of work for more than a short period. Worker burnout, de- layed equipment maintenance, and increased costs make it undesirable to operate at very high utilization over the medium or long term for most firms. In addition to the theoretical peak capacity, there is an effective capacity that is obtained by subtracting downtime for maintenance, shift breaks, schedule changes, absenteeism, and other activities that d ecrease the capacity available. The effective capacity, then, is the amount of capacity that can be

- 8. used in planning for actual facility output over a period of time. To estimate effective capacity for the previously described two-shift facility, we must subtract hours for planned and unforeseen events. l li I I 288 Part Four Capacity and Scheduling 12.1 FACILITIES DECISIONS "OM: Featuring St. Alexius Medical Center," Vol. X Facilities decisions, the longest-term capacity planning decisions, are of gm1 importance to a firm. These decisions place physical constraints on the amo.- that can be produced, and they often require significant capital investm~ Therefore, facilities decisions involve all organizational functions and often made at the highest corporate level, including top management and the b~ of directors.

- 9. Firms must decide whether to expand existing facilities or build new ones. _ we discuss the facilities strategy below, we will see there are trade-offs that mm be considered. Expanding current facilities may provide location conveniences current employees but may not be the best location in the long- run. Alternativell new facilities can be located near a larger potential workforce but require duplial- tion of activities such as maintenance and training. When construction is required, the lead time for many facilities decisions r~ from one to five years. The one-year time frame generally involves buildings - equipment that can be constructed quickly or leased. The five- year time frame volves large and complex facilities such as oil refineries, paper mills, steel millll and electricity generating plants. In facilities decisions, there are five crucial questions: 1. How much capacity is needed? 2. How large should each facility be? 3. When is the capacity needed? 4. Where should the facilities be located? 5. What types of facilities/ capacity are needed? The questions of how much, how large, when, where, and what type can be s~ rated conceptually but are often intertwined in practice. As a result, facilities deci-

- 10. sions are exceedingly complex and difficult to analyze. In the next section, these five types of facilities decisions are considered in de- tail. We stress the notion of a facilities strategy, cross- functional decision ma:king and the relationship of facilities strategy to business strategy. 12.2 FACILITIES STRATEGY In Chapter 2 it was noted that a facilities strategy is one of the major parts of - operations strategy. Since major facilities decisions affect competitive success they need to be considered as part of the total operations strategy, not simply as a series of incremental capital-budgeting decisions. Supporting the operatioot strategy also applies to other major strategic decisions in operations regardind process design, the supply chain, and quality management, as we have already noted. A facilities strategy considers the amount of capacity, the size of facilities, the timing of capacity changes, facilities locations, and the types of facilities needed for the long run. It must be coordinated with other functional areas due to the necessary investments (finance), market sizes that determine the amount ot capacity needed (marketing), workforce issues related to staffing new facilities (human resources), estimating costs in new facilities (accounting), and technology

- 11. decisions regarding equipment investments (engineering). The facilities strategy Amount of Capacity FACILITIES STRATEGY. This Bacardi Rum factory supplies the entire North American market from a single modern automated distillery in Puerto Rico. Chapter 12 Capacity Planning 289 needs to be considered in an integrated fashion with these functional areas and will be affected by the following factors: 1. Predicted demand. Formulating a facility strategy requires a forecast of de- mand; ·techniques for making these forecasts were considered in the previous chap- ter. Marketing often is involved in forecasting future demand. 2. Cost of facilities. Cost is driven by the amount of capacity added at one time, the timing, and the location of capacity. Accounting and finance are involved in estimating future costs and cash flows from facility strategies. 3. Likely behavior of competitors. An expected slow

- 12. competitive response may lead the firm to add capacity to grab the market before competitors become strong. In contrast, an expected fast competitive response may cause the firm to be more cautious in expanding capacity. 4. Business strategy. The business strategy may dictate that a company put more emphasis on cost, service, or flexibility in facilities choices. For exam- ple, a business strategy to provide the best service can lead to facilities with some excess capacity or several market locations for fast service. Other busi- ness strategies can lead to cost minimization or attempts to maximize future flexibility. 5. International considerations. As markets and supply chains continue to be- come more global in nature, facilities often are located globally. This involves not merely chasing cheap labor but locating facilities for the best strategic ad- vantage, sometimes to access new markets or to obtain desired expertise in the workforce. One part of a facilities strategy is the amount of capacity needed. This is deter- min~d both by forecasted demand and by a strategic decision by the firm about how much capacity to provide in relation to expected demand. This can best be described by the notion of a capacity cushion, which is defined

- 13. as follows: Capacity cushion = 100% - Utilization The capacity cushion is the difference between the output that a firm could achieve and the real output that it produces to meet demand. Since capacity utilization reflects the output required to satisfy demand, a positive cushion means that there is more capacity available than is required to satisfy demand. Zero cushion means that the average demand equals the capacity available. 290 Part Four Capacity and Scheduling Size of Facilities The decision regarding a planned amount of cushion is strategic in na~ The capacity cushion should be planned into capacity decisions, as the cushiOIIC will affect service levels as well as the firm's ability to respond to unexpectel situations. Three strategies can be adopted with respect to the amount of capacity cushi• 1. Large cushion. In this strategy, a large positive capacity cushion, with ca- pacity in excess of average demand, is planned. The firm intentionally has

- 14. more capacity than the average demand forecast. This type of strategy is ap- propriate when there is an expanding market or when the cost of buildinfl and operating capacity is inexpensive relative to the cost of running out capacity. Electric utilities adopt this approach, since blackouts and brown-- outs are generally not acceptable. Firms in growing markets may adopt a positive capacity cushion to enable them to capture market share ahead 01 their competitors. Also, a large cushion can help a firm meet unpredictabll customer demand, for example, for new technologies that very quickly be- come popular. Firms using a make-to-order process usually have a signifiJ cant capacity cushion. 2. Moderate cushion. In this strategy, the firm is more conservativ e with respect to capacity. Capacity is built to meet the average forecasted demand comfort- ably, with enough excess capacity to satisfy unexpected changes in demand as long as the changes are not hugely different from the forecast. This strategy is used when the cost (or consequences) of running out is approximately in bal- ance with the cost of excess capacity. • 3. Small cushion. In this strategy, a small or nearly zero capacity cushion is planned to maximize utilization. This strategy is appropriate when capacity is

- 15. very expensive, relative to stockouts, as in the case of oil refineries, paper mills, and other capital-intensive industries. These facilities operate profitably only at very high utilization rates between 90 and 100 percent. While this strategy tends to maximize short-run earnings, it can be a disadvantage if competitors adopt larger capacity cushions. Competitors will be able to meet any demand in excess of a firm ' s capacity. Make-to-stock processes are likely to plan a small capacity cushion using this strategy. When planning the capacity cushion, firms assess the probability of various levels of demand and then use those estimates to make decisions about planned increases or decreases in capacity. For example, suppose a firm has capacity to produce 1200 units, SO percent probability of 1000 units of demand, and SO percent probability of 800 units of demand. Then average demand is estimated to be (.S X 1000) + (.S X 800) = 900 units. Producing 900 units results in a (900 / 1200) X 100% = 7S% utilization rate. Based on existing capacity, the cushion is (100% - 7S%) = 2S%. The solved problems section at the end of the chapter provides an example of how to compute the capacity cushion by using probabilities of demand, existing levels of capacity, and costs of building capacity. This method provides a quantita- tive basis for estimating the amount of capacity cushion that

- 16. may be required. After deciding on the amount of capacity to be provided, a facilities strategy must address how large each unit of capacity should be. This is a question involving economies of scale, based on the notion that large facilities are gen erally more economical because fixed costs can be spread over more units of production. FIGURE 12.2 Optimum facility size. Timing of Facility Decisions Unit Cost Economies of scale Facility Size (units produced per year) Chapter 12 Capacity Planning 291 Economies of scale occur for two reasons. First, the cost of building and operating large production equipment does not increase linearly with volume. A machine with

- 17. twice the output rate gener- ally costs less than twice as much to buy and operate. Also, in larger facilities the overhead related to manag- ers and staff can be spread over more units of production. As a result, the unit cost of production falls as facil- ity size increases when scale economies are present, as shown in Figure 12.2. This is a good news-bad news story, for along with economies of scale come diseconomies of scale. As a facility gets larger, diseconomies can occur for several reasons. First, logistics diseconomies are present. For example, in a manufacturing firm, one large facility incurs more transportation costs to deliver goods to mar- kets than do two smaller facilities that are closer to their markets. In a service firm, a larger facility may require more movement of customers or materials, for exam- ple, moving patients around a large hospital or moving mail through a regional sorting center. Diseconomies of scale also occur because coordination costs in- crease in large facilities. As more layers of staff and management are added to manage large facilities, costs can increase faster than output. Furthermore, costs related to complexity and confusion rise as more products or services are added to a single facility. For these reasons, the curve in Figure 12.2 rises on the right-hand

- 18. side due to diseconomies of scale. As Figure 12.2 indicates, there is a minimum unit cost for a certain facility size. This optimal facility size will depend on how high the fixed costs are and how rapidly diseconomies of scale occur. As an example, Hewlett- Packard tends to op- erate small plants of fewer than 300 workers, with relatively low fixed costs. This plant size helps Hewlett-Packard encourage innovation in its many small product lines. By contrast, IBM operates very large plants of 5000 to 10,000 workers. IBM plants tend to be highly automated, and they use a decentralized management ap- proach to minimize diseconomies of scale. Each firm seems to have an optimal facility size, depending on its cost structure, product/ service mix, and particular operations strategy, which may emphasize cost, delivery flexibility, or service. Cost is, after all, not the only factor that affects facility size. Another element of facilities strategy is the timing of capacity additions. There are basically two opposite strategies here. 1. Preempt the competition. In this strategy, the firm leads by building capacity in advance of the needs· of the market. This strategy provides a positive capacity cushion and may actually stimulate the market while at the same time prevent- ing competition from coming in for a while. Apple Inc. used this strategy in the

- 19. early days of the personal computer market. Apple built capacity in advance of demand and had a lion's share of the market before competitors moved in. Apple still uses this strategy today in building massive capacity and invento- ries in advance of new product launches for the iPad and iPhone. 292 Part Four Capacity and Scheduling Facility Location "Wind Farm Capacity," Vol. XVII Types of Facilities 2. Wait and see. In this strategy, the firm waits to add capacity until demand develops and the need for more capacity is clear. As a result, the company lags market demand, using a lower- ·risk strategy. A small or negative capaci cushion can develop, and a loss of poten · market share may result. However, this stra~ egy can be effective because superior market- ing channels or technology can allow the follower to capture market share. For examplE;. in the 1980s, IBM followed the leader (Apple in the personal computer market but was able

- 20. to take away market share because of its supe- rior brand image, size, and market presence. In contrast, U.S. automobile companies followed the wait-and-see strategy, to their chagrin, for sma ll autos. While U.S. automakers waited to see how demand for small cars would develop, Japanese manufacturers grabbed a dom- inant position in the U.S. small-car market. Facility location decisions have become more complex as globalization has ex- panded the options for locating capacity and developing new markets. For example. Starbucks may choose to build facilities in regions with heavy coffee drinkers, com- peting for customers there. Alternatively, it may choose to locate facilities in regions where people typically do not consume coffee and attempt to create demand foc their product and service. Starbucks's U.S. competitor Caribou Coffee goes to great lengths to find facilities locations on the right-hand side of the road of morning traf- fic, because customers are more likely to stop frequently when they can pull over on the right but are less willing to make cumbersome left-hand turns in heav y traffic! Location decisions are made by considering both quantitative and qualitative fac- tors. Quantitative factors that affect the location decision may include return on in- vestment, net present value, transportation costs, taxes, and lead times for delivering

- 21. goods and services. Qualitative factors can include language and norms, attitudes among workers and customers, and proximity to customers, suppliers, and competi- tors. Front office services in particular must often locate near customers for the customers' convenience, and so this factor may trump most others in deciding where to locate new facilities. Examples include banks, grocery stores, and restaurants. Firms often compare potential locations b y weighting the importance of each factor that is relevant to the decision and then scoring each potential location on those factors . Then, multiplying the factor w eight by the location score allows cal- culation of a weighted-av erage score for each site. This score provides insight on how well each potential site meets the needs of the firm and may b e used to make the final facility location decision. The final element in facility strategy considers the question of what the firm plans to accomplish in each facility. There are four different types of facilities: 1. Product-focused (55 p ercent) 2. Market-focused (30 p ercent) 3. Process-focused (10 p ercent) 4. General-purpose (5 p ercent)

- 22. Chapter 12 Capacity Planning 293 The figures in parentheses indicate the approximate percentages of companies in the Fortune 500 using each type of facility. Product-focused facilities produce one family or type of product or service, usually for a large market. An example is the Andersen Window plant, which pro- duces various types of windows for the entire United States from a single product- focused plant. Product-focused plants often are used when transportation costs are low or economies of scale are high. This tends to centralize facilities into one location or a few locations. Other examples of product-focused facilities are large bank credit card processing operations and auto leasing companies that process leases for cars throughout the United States from a single site. Market-focused facilities are located in the markets they serve. Many service facilities fall into this category since services generally cannot be transported. Plants that require quick customer response or customized products or that have high transportation costs tend to be market focused. For example, due to the bulky nature and high shipping costs of mattresses, most production plants are located in regional markets. International facilities also tend to be market focused because of tariffs, trade barriers, and potential currency fluctuations.

- 23. Process-focused facilities have one technology or at most two. These facilities frequently produce components or subassemblies that are supplied to other facili- ties for further processing. This is common in the auto industry, in which en- gine plants and transmission plants feed the final assembly plants. Process-focused plants such as oil refineries can make a wide variety of products within the given process technology. Operations Leader Strategic Capacity Planning at BMW ' Mathematical optimization models (e.g., mixed linear programming) can be helpful in evaluating various ca- pacity strategies. Given a forecast of demand over the next several years, the models will determine the min- imum cost plan for meeting the demand . An example from BMW helps explain this process. BMW used a 12-year future planning horizon to rep- resent the typical development and production life cycle for new BMW designs. The mathematical model calculated the supply of finished products that should be produced by each plant to meet the forecasts in all global markets. As a result, the model determined how much of each product should be produced in each plant over the next 12 years. All possible locations, amounts, and types of BMWs were considered by the mathe- matical model in arriving at the minimum cost plan. This type of analysis is very helpful in setting overall

- 24. capacity strategies for how much, how large, where, when, and what type. For example, the resulting strat- egy might be to use distributed production to pro- duce in each national market the amount sold there or a more centralized production and export strategy. Due to the many assumptions made, the models do not determine the final capacity strategy; however, they are very helpful in evaluating many different possibilities. Source: Fleischmann B., Ferber S. and Henrich P., " Strategic planning of BMW's Global Production Network," Interfaces, 2006, 36(3): 194-208 .. li II II II 11 II II 294 Part Four Capacity arul Scheduling General-purpose facilities may produce several types of products and sel'- vices, using several different processes. For example, general- purpose facilities a.rr used to manufacture furniture and to provide consumer banking and investmenll services. General-purpose facilities usually offer a great deal of

- 25. flexibility in terms of the mix of products or services that are produced there. They sometimes are used by firms that do not have sufficient volume to justify more than one facili~ Larger firms often focus their faCilities according to product, market, or procesa using the focused factory approach described in Chapter 4. We have shown how the facilities strategy can be developed by con siderind questions of capacity, size of facilities, timing, location, and types of facilities. Mathematical optimization models can often be helpful in answering these five strategic questions as shown in the BMW Operations Leader box. We now shift from long-term facilities decisions to medium-term decisions regarding how capacity, once built, is used. 12.3 SALES AND OPERATIONS PLANNING DEFINITION Sales and operations planning (S&OP) is a term used by many firms to describe the aggregate planning process. Aggregate planning is the activity of matching supply of output with demand over the medium time range. The time frame is between six months and two years into the future, or an average of about one year. The term ag- gregate implies that the planning is done for a single overall measure of output or at most a few aggregated product categories. The aim of S&OP is to set overall output levels in the medium-term future in the face of fluctuating or

- 26. uncertain demand. We use a broad definition of S&OP with the following characteristics: 1. A time horizon of about 12 months, with updating of the plan on a periodic basis, perhaps monthly. 2. An aggregate level of demand for one or a few categories of product. The de- mand is assumed to be fluctuating, unc~rtain, or seasonal. 3. The possibility of changing both supply and demand variables. 4. A variety of management objectives, which might include low inv entories, good labor relations, low costs, flexibility to increase future output levels, and good customer service . 5. Facilities that are considered fixed and cannot be expanded or reduced. As a result of S&OP, decisions related to the workforce are made concerning hir- ing, laying off, overtime, and subcontracting. Decisions regarding production out- put and inventory levels are also made. S&OP is used not only to plan production output levels but also to determine the appropriate resource input mix to use. Since facilities are assumed to be fixed and cannot be expanded or contracted, manage- ment must consider how to use facilities and resources to best

- 27. match market demand. S&OP can involve plans to influence demand as well as supply. Factors such as pricing, advertising, and product mix may be considered in planning for the me- dium term. We will discuss these tactics more later in this chapter. S&OP generally is done b y product family, that is, a set of similar products or services that more or less share a production process, including the equipment and workforce needed to produce output. Usually no more than a few product Chapter 12 Capacity Planning 295 Operations Leader S&OP for Household Cleaning Products Reckitt Benckiser, with £9 billion in sales in 180 coun- tries, has some of the world's most famous brands, in- cluding Vanish, Lysol, Calgon, and Airwick. In rapidly changing retail markets, rapid adjustments in produc- tion and sales are needed. Because Reckitt has over 500 products in its portfolio, an S&OP system was needed to coordinate its supply chain. The S&OP system has been successful, allowing Reckitt Benckiser to capture 70 percent of grocery store sales from products that rank first or second in their categories. Its S&OP team consists of managers

- 28. from marketing, sales, production, distribution, and R&D. Before S&OP, Reckitt Benckiser often used dif- ferent forecast numbers in different parts of the or- ganization. It is now able to manage its brands by "using one set of numbers," says Ariston Banaag. The team meets regularly to review forecasts and update plans. The team uses software from Demand Solution s to track sales, forecasts, and plans for all its brands and products. Source: Adapted from www.demandsolutions.com, 2009 and www.rb.com, 2012. families are used for S&OP to limit the complexity of the planning process. Inconsistencies between supply and demand are resolved by revising the plan as conditions change. S&OP matches supply and demand by using a cross-functional team ap- proach. The cross-functional team consisting of marketing, sales, engineering,

- 29. human resources, operations, and finance meets with the general manager to agree on the sales forecast, the supply plan, and any steps needed to modify supply or demand. During the S&OP process, demand is decoupled from sup- ply. For each product family, the cross-functional team must decide whether to produce inventory, manage customer lead time, provide additional capacity (internal or external), or restrict demand. Once plans to manage demand and supply are in balance, however, the current plan may not agree with previous financial plans or human resources plans or budgets, which also may need to be modified. The resulting sales and operations plan is updated approximately monthly, us- ing a 12-month or longer rolling planning horizon. At its best, S&OP reduces mis- alignment among functions by requiring a common plan to be implemented by all parties. Strong general manager leadership may be required to

- 30. resolve any con- flicts that arise. Read the Operations Leader box to learn how S&OP is done for household cleaning products at Reckitt Benckiser. Syngenta is a world leader in agribusiness products, with 19,000 employees in 90 countries. The highly seasonal agricultural market is difficult to forecast and experiences large demand shifts. Syngenta uses S&OP to create collaboration across functions and with its supply chain partners. Managers across several countries use the S&OP process and the supporting software to gain better agree- ment on forecasts, sales promotions, inv entory levels, sales plans, and aggregate 296 Part Four Capacity and Scheduling production plans. Real-time Web collaboration allows each business unit to y~ ticipate in the S&OP process to achieve targeted business

- 31. goals.1 Since S&OP is a form of aggregate planning, it precedes detailed schedulioj which is covered in the next chapter. Scheduling serves to allocate the capa<4 made available by aggregate planning to specific jobs, activities, or orders. 12.4 CROSS-FUNCTIONAL NATURE OF S&OP Aggregate planning for how capacity will be used in the medium-term future the primary responsibility of the operations function. However, it requires cross- functional coordination and cooperation with all functions in the firm, includiolll accounting, finance, human resources, and marketing. S&OP or aggregate planning is closely related to other business decisions in- volving, for example, budgeting, personnel, and marketing. The relationship budgeting is particularly strong. Most budgets are based on assumptions aboul

- 32. aggregate output, personnel levels, inventory levels, purchasing levels, and forth. An aggregate plan thus should be the basis for initial budget developm~ and for budget revisions as conditions warrant. Personnel, or human resource planning, is also greatly affected by S&OP be- cause such planning for future production can result in hiring, lay of, and overti:md decisions. In service industries, which cannot use inventory as a buffer againsl changing demand, aggregate planning is sometimes synonymous with budgetinG and personnel planning, particularly in labor-intensive services that rely heavily on the workforce to deliver services. • Marketing must always be closely involved in S&OP because the future supplJI of output, and thus customer service, is being determined. Furthermore, coop era-- tion between marketing and operations is required when both supply and de- mand variables are used to determine the best business approach

- 33. to aggregate planning. The next section contains a detailed discussion of the options available to modify demand and supply for aggregate planning. This is followed by the development of specific strategies that can be used to plan aggregate output foc both manufacturing and service industries. S&OP is not a stand-alone system. It is a key input into the enterprise resource planning (ERP) system, which is discussed in Chapter 16. ERP tracks all d etailed transactions from orders to shipments to payments, but requires a high-level ag- gregate plan for future sales and operations as an input. When the S&OP p rocess is used, various scenarios and assumptions can be tested by simulation to arrive at an agreed-upon plan that all functions will implement. The ERP system then ac- cepts as input the S&OP plan and projects the detailed transactions (shop orders, purchase orders, inventories, and payments) that are required to support the

- 34. agreed plan. Figure 12.3 captures these inputs and outputs from an S&OP process. In some firms, the S&OP process is broken or missing. Top management does not actively support or participate in the process. Accountability for S&OP is in- adequate or in conflict across functions. The firm's information system may not support S&OP, and so the firm is not able to conduct important "what if" analy- sis. Also, S&OP plans may not be executed by all organizational functions as has been agreed. Therefore, to be successful, the S&OP system may require changes in the organization, reporting and accountability, and the information systems. 1 Herrin (2004). FIGURE 12.3 lelationship of S&OP with other

- 35. lanctions. Accounting -Cost analysis Finance Operations - Forecast - Inventory levels -Capacity -Current orders - Investment Marketing -Forecast -Sales plan / S&OP ")

- 36. , Process 1 1 "-.... /// " ........ ---- .,. Chapter 12 Capacity Planning 297 Human Resources - Personnel planning 12.5 PLANNING OPTIONS Operations and marketing must work closely to plan for matching supply and demand over the medium-term time frame. They do this during aggregate plan- ning when they coordinate their decisions to develop enough demand for prod- ucts and services without overshooting available facility capacity. The S&OP process can be clarified by a discussion of the various decision op- tions available. These include two categories of decisions: (1)

- 37. those modifying de- mand and (2) those modifying supply. Demand management entails modifying or influencing demand in several ways: 1. Pricing. Differential pricing often is used to reduce peak demand or to build up demand in off-peak periods. Some examples are matinee movie prices, off- season hotel rates, factory discounts for early- or late-season purchases, and off-peak specials at restaurants. The purpose of these pricing schemes is to level demand through the day, week, month, or year. 2. Advertising and promotion. These methods are used to stimulate or in some cases smooth out demand. Advertising can be timed to promote demand dur- ing slack periods and shift demand from peak periods to slack times. For ex- ample, ski resorts advertise to lengthen their season and turkey growers

- 38. advertise to stimulate demand outside the peak holiday seasons. 3. Backlogs or reservations. In some cases, demand is influenced by asking cus- tomers to wait for their orders (backlog) or by reserving capacity in advance (reservations). Generally, this has the effect of shifting demand from peak 298 Part Four Capacity and Scheduling "Service Design at Hotel Monaco," Vol. IX periods to periods with slack capacity. However, the waiting time may resu a loss of business. This loss can be tolerated when the aim is to maximize~ although most operations are extremely reluctant to tum away customers.

- 39. 4. Development of complementary offerings. Firms with highly seasonal mands may try to develop products that have countercyclic seasonal trends. example, Taro produces both lawn mowers and snow blowers, seasonally ~ plementary products that can share production facilities. In fast- food reslil rants, breakfast has been added in many cases to utilize previously idle capaq The service industries, using all the mechanisms described above, have .: much further than most of their manufacturing counterparts in influencing mand. Because they are unable to inventory their output-their services---til use these mechanisms to improve their utilization of fixed facility capacity. Supply management includes a variety of factors that can be used to increase decrease supply through aggregate planning. These factors include the followinll

- 40. 1. Hiring and laying off employees. Some firms will do almost anything ~ reducing the size of the workforce through layoffs. Other companies routinll increase and decrease the workforce as demand changes. These practices, "' vary widely by firm and industry, affect not only costs but also labor relatiollll productivity, and worker morale. As a result, company hiring and layoff p~ tices may be restricted by union contracts or company policies. These effedll must be factored into decisions about whether to change the size of the w0111 force to match demand more closely. 2. Using overtime and undertime. Overtime sometimes is used for short- medium-range labor adjustments in lieu of hiring and layoffs, especially if change in demand is considered temporary. Overtime labor usually costs 1 percent of regular time, with double time on weekends and holidays. BecaU!IIIII

- 41. of its high cost, managers are sometimes reluctant to use overtime. F~ more, workers may be reluctant to work more than 20 percent weekly overt:ioll for an extended p eriod. Undertime refers to planned underutilization of ~ workforce rather than layoffs, perhaps by using a shortened workweek. Undefll time, in the form of furloughs, was common in many industries, includillllll manufacturing, education, and government, during the recessionary months 2008-2009. 3. Using part-time or temporary labor. In some cases, it is possible to hire pan< time or temporary employees to meet peak or seasonal demand. This option particularly attractive when part-time employees are paid significantly less wages and benefits. Unions frequently frown on the use of part- time employe~!~ because those employees often do not pay union dues and may weaken uni~ influence. Temporary labor is more likely to be used to satisfy

- 42. seasonal or shod-· to medium-term demand. Part-time labor and temporary labor are used exten- sively in many service operations, such as restaurants, hospitals, su permarkel!i and department stores. Temporary labor is also common in agriculture-relatel industries. 4. Carrying inventory. In manufacturing firms, inventory can be used as a buffer- between supply and demand. Inventories for later use can be built up during periods of slack demand. Inventory thus decouples supply from demand in manufacturing operations, allowing for smoother operations with more even use of capacity throughout a time period. Inventory is a way to store expended Chapter 12 Capacity Planning 299 capacity and labor for future consumption. This option is

- 43. generally not avail- able for service operations; this results in greater challenges for service indus- tries in matching supply and demand. 5. Subcontracting. Subcontracting is the outsourcing of work (either manufactur- ing or service activities) to other firms. This option can be very effective for in- creasing or decreasing supply. The subcontractor may supply the entire product or service or only some of the components. For example, a manufacturer of toys may utilize subcontractors to make plastic parts during periods of high de- mand. Service operations may subcontract secretarial assistance, call center op- erations, catering services, or facilities during peak periods. 6. Cooperative arrangements. These arrangements are similar to subcontracting in that other sources of supply are used, but cooperative arrangements often in- volve partner firms that are typically competitors. The firms choose to share their

- 44. capacity, thus preventing either firm from building capacity that would be used only during brief periods. Examples include electric utilities that link their capac- ity through power-sharing networks, hospitals that send patients to other hospi- tals either for certain specialized services or during demand peaks, and hotels or airlines that shift customers among one another when they are fully booked. In considering all these options, it is clear that S&OP and the aggregate plan- ning problem are extremely broad and affect most parts of the firm. The decisions that are made are therefore strategic and cross-functional, reflecting all the firm's objectives. If aggregate planning is considered narrowly, inappropriate decisions result and suboptimization may occur. Some of the multiple trade-offs that should be considered are customer service level (through back orders or lost demand), inventory levels, stability of the labor force, and costs. The conflicting objectives

- 45. and trade-offs among these elements sometimes are combined into a single cost function. A method for evaluating costs is described later in this chapter. 12.6 BASIC AGGREGATE PlANNING STRATEGIES When demand slumped, the Parker Hannifin plastic parts manufacturing plant in Spartanburg, South Carolina, kept its workforce but reduced work hours where Using a level strategy often results in holding inventory during low demand periods. possible. In contrast, the investment firm Goldman Sachs laid off 10 percent of its workforce in late 2008 and another 10 percent in early 2009. In this section, we discuss the aggregate planning strate- gies used in each of these instances and explain how firms decide which strategy is best for them. Two basic planning strategies can be used, as well as combinations of them, to meet medium- term aggregate demand. One strategy is to main-

- 46. tain a level workforce; the other is to chase demand with the workforce. With a perfectly level strategy, the size of the workforce and the rate of regular-time output are constant. Any variations in demand must be absorbed by using inventories, overtime, temporary workers, subcontracting, cooperative 300 Part Four Capacity and Scheduling Operations Leader Travelers' Level Strategy Meets Demand Variation Travelers offers a wide variety of insurance products and services, covering customers in more than 90 countries. It sells insurance for auto owners, renters, home owners, TRAVELER 5 'f , ~;a~~~~~n~:s:~ example of a

- 47. service firm that uses a level strategy to manage its workforce and capacity. Before Hurricane Ike slammed the Texas coast in September 2008, Travelers claims employees from around the United States were moving toward the af- fected areas so that they would be immediately avail- able to serve affected customers. Even before the storm made landfall, teams of trained and equipped claims professionals were ready. The company's Na- tional Catastrophe Response Center had plans in place to quickly deploy thousands of cross-trained employ- ees from other regions to help customers rather than, as is customary in the industry, relying on out- side contractors. Travelers uses a level strategy, with workers from many regions pitching in during large-scale disasters and workers being diverted to training and catch-up activities during slow times when it might appear to be overstaffed. The strategy seems to pay off in terms of maintaining high levels of customer service during a peak demand period. Travelers was able to contact most of its Hurricane Ike-affected customers

- 48. within 48 hours of their reporting a claim and to in- spect, provide payment, and close the majority of claims within 30 days. Source: Adapted from annual report, www.travelers.com, 2009. arrangements, or any of the demand-influencing options discussed above. The level strategy essentially holds the regular workforce at a fixed number, and so the rate of workforce output is fixed over the aggregate planning period . However, a firm using a level strategy can respond to fluctuations in demand by using the demand and supply planning options discussed in the previous section. With the chase strategy, the size of the workforce is changed to meet, or chase, demand. With this strategy, it is not necessary to carry inventory or use the de- mand and supply planning options available for aggregate planning; the work-

- 49. force absorbs all the changes in demand. The chase strategy generally results in a fair amount of hiring and laying off of workers as demand is chased. These two strategies are extremes; one strategy makes no change in the work- force, and the other varies the workforce directly with demand changes. In prac- tice, many firms use a combination of these two strategies. Read the Operations Leader box to see how Travelers Insurance successfully uses a level strategy even though demand for its service can vary significantly. Consider, for example, a brokerage firm that utilizes both strategies. The data processing department maintains the capacity to process 17,000 transactions per day, far in excess of the average load of 12,000. This capacity allows the depart- ment to keep a level workforce of programmers, systems analysts, and computer operators even though capacity exceeds demand on many days. Because of the

- 50. skilled workforce, the high capital investment, and the difficulty and expense of hiring replacements, the data processing department chooses to follow a level strategy. Meanwhile, in the cashiering department, a chase strategy is used. As the transaction level varies, part-time workers, hiring, and layoffs are used. This de- partment is very labor-intensive, with high worker turnover and low skill levels TABLE 12.1 ,.Comparison of Chase and Level Strategies Level of labor skill required Job discretion Compensation rate Training required per employee

- 51. Labor turnover Hire-layoff costs per employee Amount of supervision required Type of budgeting and forecasting required Chapter 12 Capacity Planning 301 Chase Strategy Low Low Low Low High Low High Short run Level Strategy High High High High Low

- 52. High Low Long run required . The manager of the department commented that the high turnover rate is an advantage, facilitating the reduction of the workforce in periods of low demand. From this scenario, we see that the characteristics of the operation seem to influ- ence the type of strategy followed . This observation can be generalized to the fac- tors shown in Table 12.1. While the chase strategy may be more appropriate for low-skilled labor and routine jobs, the level strategy seems better for highly skilled labor and complex jobs. These strategies can be compared in terms of their costs to provide insight into the better choice, depending on the particular situation a firm faces. The relevant factors in this decision are represented by their cost, allowing

- 53. us to develop mod- els to compare the two strategies, as described in the next section. 12.7 AGGREGATE PLANNING COSTS . Most aggregate planning methods include a plan that minimizes costs. These methods assume that demand is given (based on forecasts) but varies over time; therefore, strategies for modifying demand are not considered. If both demand and supply are modified simultaneously, it may be more appropriate to develop a model to maximize profit rather than minimize costs, since demand changes affect revenues along with costs. When demand is given, the following costs should be included: 1. Hiring and layoff costs. Hiring costs consist of the recruiting, screening, and training costs required to bring a new employee up to full productive skill. For

- 54. some jobs, this cost may be only a few hundred dollars; for more highly skilled jobs, it may be thousands of dollars. Layoff costs include employee benefits, severance pay, and other associated costs. This cost also may range from a few hundred to several thousand dollars per worker. When an entire shift of work- ers is hired or laid off, a shift cost must be accounted for. 2. Overtime and undertime costs. Overtime costs consist of regular wages plus an overtime premium, typically an additional 50 to 100 percent. Undertime costs reflect the use of employees at less than full productivity. 3. Inventory-carrying costs. Inventory-carrying costs are associated with main- taining goods in inventory, including the cost of capital, the variable cost of stor- age, obsolescence, and deterioration. These costs often are expressed as a percentage of the dollar value of inventory, ranging from 15 to 35 percent per year.

- 55. 302 Part Four Capacity and Scheduling This cost can be thought of as an interest charge assessed against the dolW value of inventory held in stock. Thus, if the carrying cost is 20 percent and each unit costs $10 to produce, it will cost $2 to carry one unit in invent0111 for a year. 4. Subcontracting costs. The cost of subcontracting is the price paid to anot:hfti firm to produce the units. Subcontracting costs can be either greater or less t:ru. the cost of producing units in-house. . 5. Part-time labor costs. Due to differences in benefits and hourly rates, the ced of part-time or temporary labor is often less than that of regular labor. Al- though part-time workers often receive no benefits, a maximum percentagtt of part-time labor may be specified by operational

- 56. considerations or by uni«mm contract. Otherwise, there might be a tendency to use all part- time or tempo-~ rary labor. However, the regular labor force is generally essential for opera- tions continuity as well as to utilize and train part-time and temporaiJI workers effectively. 6. Cost of stockout or back order. The cost of taking a back order or the cost ot a stockout should reflect the effect of reduced customer service. This cost is extremely difficult to estimate, but it should capture the loss of custom~ goodwill, the loss of profit from the order, and the possible loss of future sales. Some or all of these costs may be relevant in any aggregate planning problem. The applicable costs can be used to "price out" alternative decisions and strate- gies. In the example below, the total costs related to three alternative strategies are

- 57. estimated. When this type of analysis is conducted o~ a spreadsheet, a very large number of alternative strategies can be considered. 12.8 AGGREGATE PLANNING EXAMPLE FIGURE 12.4 Hefty Beer Company- demand forecast. The Hefty Beer Company is constructing an aggregate plan for the next 12 months. Although several types of beers are brewed at the Hefty plant and several con- tainer sizes are bottled, management has decided to use gallons of beer as the ag- gregate measure of capacity. The demand for beer over the next 12 months is forecast to follow the p attern shown in Figure 12.4. Notice that demand peaks during the summer months and is decidedly lower in the winter.

- 58. 700 600 8 0 3 500 "' c:< 0 ~ 400 0 300 200 I ~ v ,/ -/ ~ lL v J F M A M J p A S 0 N D

- 59. Month Chapter 12 Capacity Planning 303 The management of the Hefty brewery would like to consider three aggregate plans: 1. Level workforce. Use inventory to meet peak demands. 2. Level workforce plus overtime. Use 20 percent overtime along with inventory in June, July, and August to meet peak demands. 3. Chase strategy. Hire and lay off workers each month as necessary to meet demand. To evaluate these strategies, management has collected the following cost and resource data: • Assume the starting workforce is 40 workers. Each worker can

- 60. produce 10,000 gallons of beer per month on regular time. On overtime, the same production rate is assumed, but overtime can be used for only three months during the year. • Each worker is paid $2000 per month on regular time. Overtime is paid at 150 percent of regular time. A maximum of 20 percent overtime can be used. • Hiring a worker costs $1000, including screening, paperwork, and training costs. Laying off a worker costs $2000, including all severance and benefit costs. • For inventory valuation purposes, beer costs $2 a gallon to produce. The cost of carrying inventory is estimated to be 3 percent per month (or 6 cents per gallon of beer per month). • Assume the starting inventory is 50,000 gallons. The desired ending inventory

- 61. a year from now is also 50,000 gallons. All forecast demand must be met; no stockouts are allowed. The next task is to evaluate each of the three strategies in terms of the costs given. The first step in this process is to construct spreadsheets like those shown in Tables 12.2 through 12.4, which show all the relevant costs: regular workforce, overtime, hiring/layoff, and inventory. Notice that subcontracting, part-time labor, and back orders/ stockouts have not been used as variables in this case. To evaluate the level strategy, we calculate the size of the workforce required to meet the demand and inventory goals. Since ending and beginning inventories are assumed to be equal, the workforce must be just large enough to meet total de- mand during the year. When the monthly demands from Figure 12.4 are summed, the annual demand is 5,400,000 gallons. Since each worker can produce 10,000(12)

- 62. = 120,000 gallons per year, a level workforce of 5,400,000--:- 120,000 = 45 workers is needed to meet the total demand. This means that five new workers must be hired. The inventories for each month and the resulting costs have been calculated in Table 12.2. Consider the calculations for January. With 45 regular workers entered at the top of the table, 450,000 gallons of beer can be produced, since each worker pro- duces 10,000 gallons in a month. The production exceeds the sales forecast by 150,000 (450,000- 300,000) gallons, which is added to the beginning inventory of 50,000 gallons to yield an inventory level of 200,000 gallons at the end of January. Next the costs in Table 12.2 are calculated as follows: Regular time costs are $90,000 in January (45 workers X $2000 each). There is no overtime cost, but 5 workers have been hired, since the starting workforce level was 40 workers. The

- 63. cost of hiring these five workers is $5000. Finally, it cost 6 cents to carry a gallon of beer in inventory for a month, and Hefty is carrying 200,000 gallons at the end of w 0 ""' TABLE 12.2 Aggregate Planning Cos ts-Strategy 1, Level Workforce* Jan. Feb. Mar. Apr. May June July Aug. Resources Regular workers 45 45 45 45 45 4 5 45 45 Overtime(%) 0 0 0 0 0 0 0 0 Units produced 450 450 450 450 450 450 450 450

- 64. Sales fo recast 300 300 350 4 00 450 500 6 50 600 Invent ory (end of month) 200 350 450 500 500 4 50 250 100 Costs Regular time $90.0 $90.0 $90.0 $90.0 $90.0 $90.0 $90.0 $90.0 Overtime 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0 .0 Hire/layoff 5.0 0 .0 0.0 0 .0 0.0 0.0 0.0 0.0 Inventory carrying 12.0 2 1.0 27.0 30.0 30.0 27.0 15.0 6.0 Total cost $ 107.0 $ 111.0 $11 7.0 $120.0 $ 120.0 $1l 7.0 $105.0 $96.0 • All costs are expressed in thousands of dollars. All production and inventory figures are in thousands of gallons. Starting inventory is 50,000 gallons. Sept. Oct. Nov. Dec. Total 4 5 45 45 45

- 65. 0 0 0 0 450 450 450 4 50 5400 4 75 475 450 450 5400 75 50 50 50 $90 .0 $90.0 $90.0 $90.0 $1080 .0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0 .0 0.0 5.0 4 .5 3.0 3.0 3.0 18 1.5 $94.5 $93.0 $93.0 $93.0 $ 1266.5 w 0 U1 TABLE. 12.3

- 66. Aggregate Planning Costs-Strategy 2, Level with Overtime* Jan. Feb. Mar. Apr. May June July Aug. Sept. Resources Regular workers 43 43 43 43 43 43 43 43 43 Overtime(%) 0 0 0 0 0 20 20 20 0 Units produced 430 430 430 430 430 516 516 516 430 Sales forecast 300 300 350 400 450 500 650 600 475 Inventory (end of month) 180 310 390 420 400 416 282 198 153 ~ Costs Regular time $86.0 $86.0 $86.0 $86.0 $86.0 $86.0 $86.0 $86 .0 $86.0 Overtime 0.0 0.0 0.0 0.0 0.0 25.8 25.8 25 .8 0.0 Hire/layoff 3.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

- 67. Inventory carrying 10.8 18.6 23.4 25.2 24.0 25.0 16.9 11.9 9.2 Total cost $99.8 $104.6 $109.4 $111.2 $110.0 $136 .8 $128.7 $123 .7 $95 .2 'All costs are expressed in thousands of dollars. All production and inventory figures are in thousands of gallons. Starting inventory is 50,000 gallons. TABLE 12.4 Aggregate Planning Costs-Strategy 3, Chase Demand* Jan. Feb. Mar. Apr. May June July Aug. Sept. Resources Regular workers 30 30 35 40 45 50 65 60 48 Overtime (%) 0 0 0 0 0 0 0 0 0 Units produced 300 300 350 400 450 500 650 600 480 Sales forecast 300 300 350 400 450 500 650 600 4 75

- 68. Inventory (end of month) 50 50 50 50 50 50 50 50 55 Costs Regular time $60 .0 $60.0 $70.0 $80.0 $90.0 $100.0 $130.0 $120.0 $96.0 Overtime 0.0 0.0 0.0 0 .0 0.0 0.0 0.0 0 .0 0.0 Hire/layoff 20.0 0.0 5.0 5.0 5.0 5.0 15.0 10 .0 24.0 Inventory carrying 3.0 3 .0 3.0 3 .0 3.0 3.0 3.0 3.0 3.3 Total cost $83.0 $63 .0 $78.0 $88.0 $198.0 $108.0 $148.0 $133.0 $1 23.3 • All costs are expressed in thousands of dollars. All production and inventory figures are in thousands of gallon s. Starting inventory is 50,000 gallons. Oct. Nov. Dec. Total 43 43 43 0 0 0

- 69. 430 430 430 5418 475 450 450 5400 108 88 68 $86.0 $86 .0 $86 .0 $1032.0 0.0 0.0 0.0 77.4 0.0 0.0 0.0 3 .0 6.5 5.3 4 .1 180.8 $92 .5 $91. 3 $90.1 $ 1293 .2 Oct. Nov. Dec. Total 47 4 5 45 0 0 0 470 450 450 5400

- 70. 475 450 4 50 5400 50 50 50 $94.0 $90.0 $90.0 $1080 .0 0.0 0 .0 0.0 0.0 2.0 4.0 0.0 95 .0 3 .0 3 .0 3.0 36.3 $99.0 $97.0 $93. 0 $ 1211.3 306 Part Four Capacity and Scheduling TABLE 12.5 Cost Summary Strategy 1-Level Regular-time payroll Hire/layoff Inventory carrying

- 71. Total Strategy 2-Level with overtime Regular-time payroll Hire/layoff Overtime Inventory carrying Total Strategy 3-C hase Regular-time payroll Hire/layoff Inventory carrying Total $1 ,080,000 5,000 181,500 $1,266,500 $1 ,032, 000

- 72. 3,000 77,400 180 ,800 $1,293,2 00 $1 ,080,000 95,000 36,300 $1,211 ,300 the month, which costs $12,000.2 These costs total $107,000 for January. The calcu- lations are continued for each month and then summed for ti;.e year to yield the total cost of $1,266,500 for the level strategy. The second strategy, level workforce plus overtime, is a bit more complicated. If X is the workforce size for option 2, we must have 9(10,000X) + 3[(1.2)(10,000X) ] = 5,400,000 gallons

- 73. For nine months Hefty will produce 10,000X gallons per month, and for three months it will produce 120 percent of 10,000X, including overtime. When the above equation is solved for X, we find X = 43 workers. In Table 12.3 we have calculated the inventories and resulting costs for this option. The third strategy, the chase strategy, varies the workforce each month by hir- ing and laying off workers to meet monthly demand exactly. When this strategy is used, a constant level of 50,000 gallons in inventory is maintained as the minimum inventory level, as shown in Table 12.4. The annual costs of the three strategies are summarized in Table 12.5. On the ba- sis of the given costs and assumptions, the chase strategy is the lowest-cost strategy. However, cost is not the only consideration. For example, the chase strategy requires building from a minimum workforce of 30 to a peak of 65 workers, and then layoffs are used to reduce the number back to 45 workers. Will the

- 74. labor climate permit this amount of hiring and laying off each year, or will this lea d to unionization and po- tentially higher labor costs? Maybe a two-shift policy or the use of part-time or tem- porary workers should be considered for peak demand portions of the year. These alternatives, along with others, should be considered in attempting to evaluate and possibly improve on the chase strategy, as we have done in the chapter supplement We have shown how to compare costs in a very simple case of aggregate planning by using three potential strategies. Advanced methods have been developed to con- sider many more strategies and more complex aggregate planning problems. These methods, which can be quite complex, include linear programming, simulation, and various decision rules. 2 For convenience, we use the end-of-month inventory to calculate inventory-carrying costs rather tha n the averag e monthly invento ry.

- 75. Chapter 12 Capacity Planning 307 12.9 KEY POINTS AND TERMS The following key points are discussed in the chapter: • Facilities decisions consider the amount of capacity, the size of units, the timing of capacity changes, facility location, and the types of facilities needed. These are long-range decisions in the hierarchy of capacity decisions. Facilities deci- sions are crucial because they determine the future availability of output and require the organization's scarce capital. • A facility strategy should be implemented rather than a series of incremental facility decisions. A facilities strategy answers the questions of how much, how large, where, when, and what type.

- 76. • The amount of capacity planned should be based on the desired risk of meeting forecast demand. The capacity cushion is a decision that firms must consider, determining whether they will use a large cushion and not run short of capacity or a small cushion with the possibility of a capacity shortage. • When it is timing capacity expansion, a firm can choose to preempt the com- petition by building capacity sooner or wait and see how much capacity is needed. • Both economies and diseconomies of scale should be considered in setting an optimum facility size. Facility location is determined by considering relevant factors in this decision and then weighing contrasting factors against one an- other. The type of facility selected is focused on product, market, process, or general-purpose needs.

- 77. • Facilities. decisions often are made by the chief executive and the board of direc- tors . Because these d ecisions are strategic in nature, they require the input of all functional areas in the firm . • Sales and operations planning (S&OP), or aggregate planning, serves as the link between facilities decisions and scheduling. S&OP decisions set output levels for the medium time range. As a result, decisions regarding workforce size, subcontracting, hiring, and inventory levels are also made. These decisions must fit within the facilities capacity available and are constrained by the re- sources av ailable. • Aggregate planning is concerned with matching supply and demand over the medium time range. There are many options for managing supply and demand. Because human resources, capital, and demand are affected, all functions must

- 78. be involved in aggregate planning decisions. • Supply factors that can be changed by aggregate planning are hiring, layoffs, overtime, under time, inventory, subcontracting, part-time labor, and coopera- tive arrangements. Factors that influence demand are pricing, promotion, back- log or reservations, and complementary products. • There are two basic .strategies for adjusting supply: the chase strategy and the level strategy. Firms can also use a combination of these two main strategies. A choice of strategy can be analyzed by estimating the total cost of each of the av ailable strategies. Factors, other than costs, to consider are cu stomer serv ice levels, d em and shifts, the labor force, and forecasting accuracy. 308 Part Four Capacity and Scheduling

- 79. Key Terms STUDENT INTERNET EXERCISES ~ • Hierarchy of capacity decisions 285 Capacity 286 Utilization 286 Effective capacity 287 Facilities decisions 288 Facilities strategy 288 Capacity cushion 289 Economies of scale 290 Diseconomies of scale 291 1. Course site: Preempt the competition 291

- 80. Wait-and-see strategy 292 Product-focused facilities 293 Market-focused facilities 293 Process-focused facilities 293 http://www.uoguelph.ca/-dsparlin!aggregat.htm General-purpose facilities 293 Sales and operations planning 294 Aggregate planning 294 Demand management 297

- 81. Supply management 298 Level strategy 299 Chase strategy 300 Read this synopsis of aggregate planning from Professor Dave Sparling's course in Canada. 2. Spreadsheet example from Georgia Southern University http://et.nmsu.edu/-etti/winter97/computers/spreadsheet.html Work through the details of this example to gain a deeper understanding of ag- gregate planning. 3. Sales and Operations Planning http://www.supplychain.com Read about S&OP on this site and come to class prepared for a discussion. 4. Demand