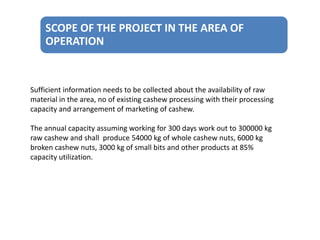

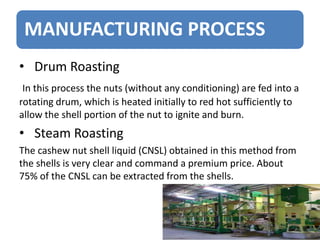

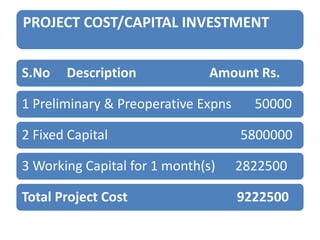

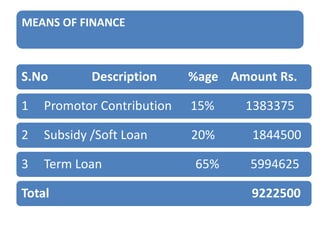

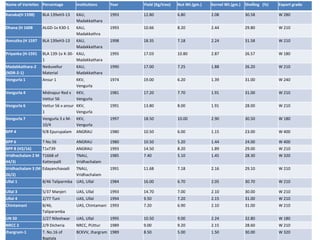

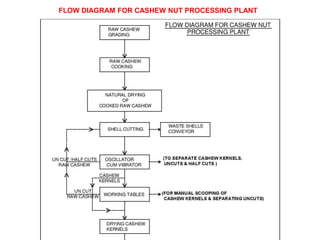

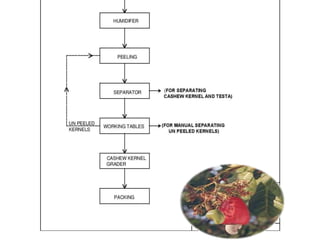

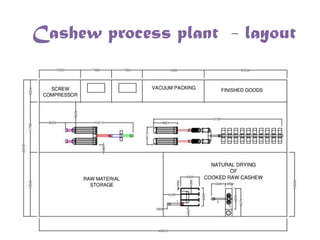

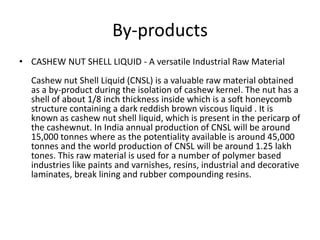

This document proposes a project for a cashew nut processing unit. It provides details on the scope, market opportunity, implementation requirements, manufacturing process, project costs, means of finance, equipment needs, cashew varieties, process flow diagrams, by-products, growth strategy, and investor exit strategy. The key points are that the proposed plant would have an annual capacity of 300,000 kg of raw cashews, cost around 9.2 crore rupees to set up, generate 35-40% returns on investment, create local employment, and have potential for exporting by-products like cashew nut shell liquid.