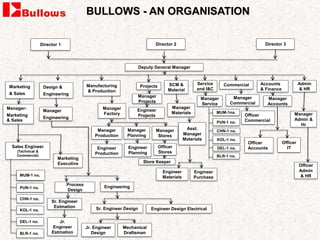

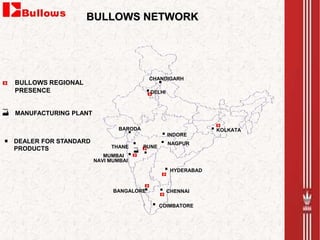

Bullows Paint Equipment Private Limited specializes in spray painting technology, offering over 50 years of experience in providing turnkey solutions for painting processes. The company serves a customer base of more than 700 clients across India and the Middle East, focusing on quality and innovative solutions in project management and after-sales support. Bullows aims to enhance finishing quality and improve processes while adhering to international standards and fostering long-term customer relationships.