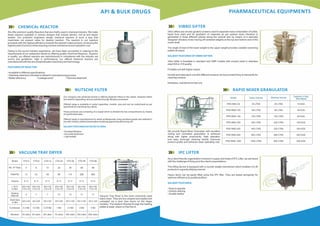

This document provides information about PRS Technology India, a manufacturer of process and packaging machinery for pharmaceutical, cosmetic, chemical, and food industries. It lists various products manufactured including pharmaceutical, chemical, and cosmetic equipment and machines. Key products described in more detail include sparkler filters, homogenizers, chemical receivers, distillation columns, planetary mixers, and multi mills. The company aims to provide high quality products along with services like product design and engineering.