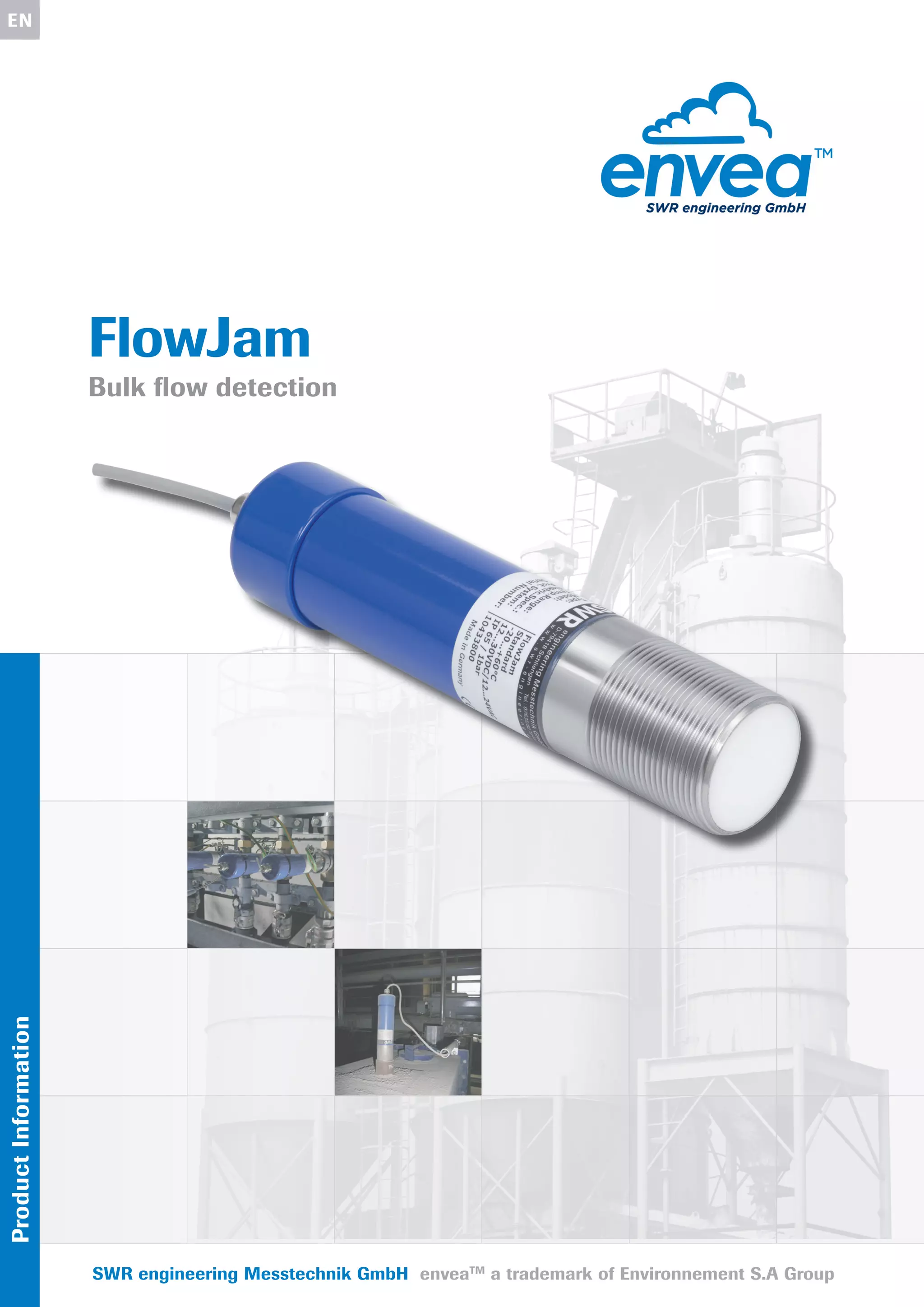

The Flowjam device utilizes microwaves for reliable bulk flow detection, capable of identifying material flow and jams through non-metallic barriers even under high temperatures and pressures. It is applicable in various industries, such as cement, gypsum, and steel, to monitor material flow continuity and prevent operational interruptions. The device features adjustable sensitivity, a robust stainless steel housing, and is designed for easy installation with various mounting options.