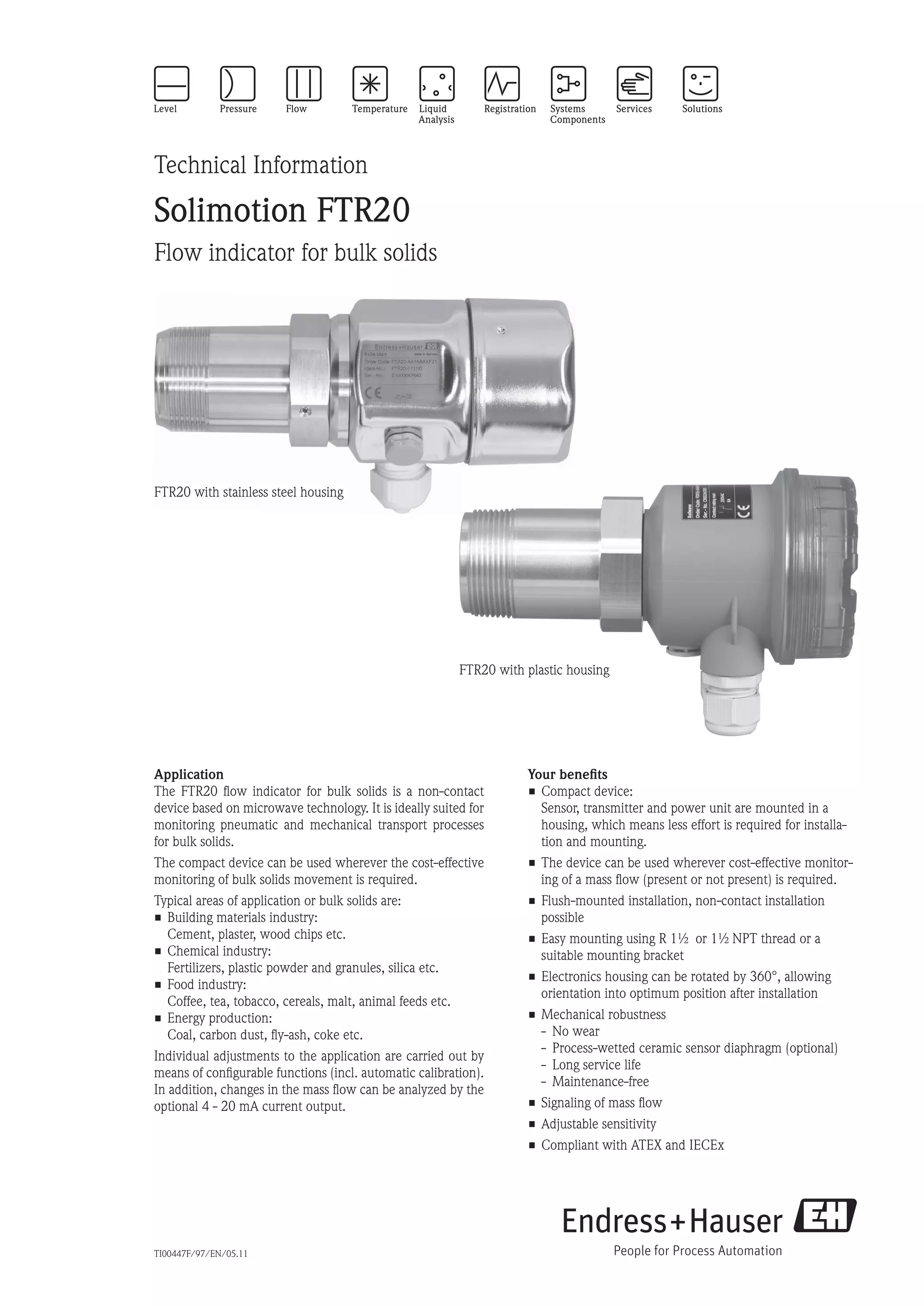

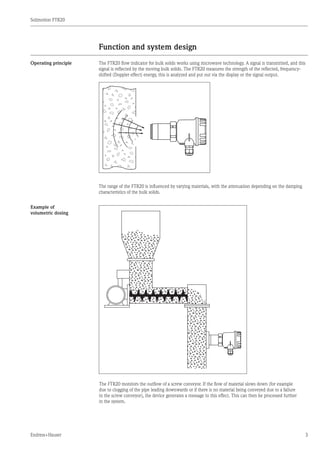

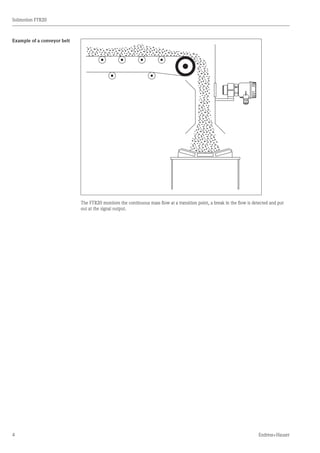

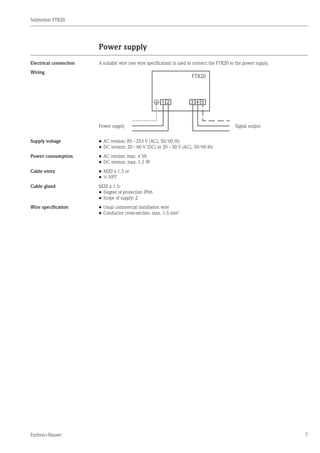

The FTR20 flow indicator for bulk solids is a compact, non-contact device that utilizes microwave technology for cost-effective monitoring of mass flow in various industries, including food, chemical, and energy production. It features adjustable sensitivity, easy installation options, and a durable design with a long service life, ensuring maintenance-free operation. Key functionalities include configurable settings, automatic calibration, and output signal capabilities to indicate changes in mass flow.