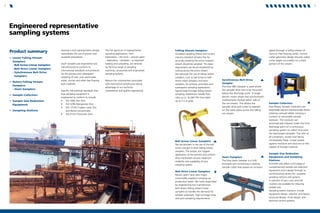

The document discusses FLSmidth's range of bulk commodity sampling equipment and engineered sampling systems. It describes their falling stream samplers, including ball screw linear samplers, belt drive linear samplers, and Vezin samplers, which are used to sample materials like ores, coal, and slurries. It also mentions their sample collectors, size reduction equipment, and capabilities to design complete sampling stations and systems for customers. FLSmidth aims to provide reliable and representative sampling solutions that conform to international standards for bulk material sampling across various industries.