The document discusses various construction materials used in building projects including cement, sand, aggregate, bricks, blocks and steel. It provides details on the types and properties of these materials. Training and skills attained are also highlighted, covering various tests performed on aggregates, concrete, soil and cement, as well as methodology, loads, foundation work, tools used, and implementation and safety precautions.

![5

Chapter 2- Training Work

2.1 Construction Materials

1.4.1 2.1.1 Cement

Cement is a cover material which makes a bond between aggregates and reinforcing materials.

Over the years. In the construction industry, there are different types of cement. The

differences between each type of cement are its properties, uses and composition materials

used during the manufacturing process.In the most general sense of the word, cement is a

binder, a substance that sets and hardens independently, and can bind other materials together.

The word "cement" traces to the Romans, who used the term opus caementicious to describe

masonry resembling modern concrete that was made from crushed rock with burnt lime as

binder. The volcanic ash and pulverized brick additives that were added to the burnt lime to

obtain a hydraulic binder were later referred to as cemented, cimentum, cement, and cement.

Cements used in construction can be characterized as being either hydraulic or non-hydraulic.

Hydraulic cements (e.g., Portland cement) harden because of hydration, a chemical reaction

between the anhydrous cement powder and water. Thus, they can harden underwater or when

constantly exposed to wet weather. The chemical reaction results in hydrates that are not very

water-soluble and so are quite durable in water. Non-hydraulic cements do not harden

underwater, slaked limes harden by reaction with atmospheric carbon dioxide. The most

important uses of cement are as an ingredient in the production of mortar in masonry, and of

concrete, a combination of cement and an aggregate to form a strong building material [1] .

Fig 2.1Port Land Cement

1.4.1.1 Physical properties

i. Fineness of cement

ii. Soundness

iii. Consistency](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-14-320.jpg)

![6

iv. Strength

v. Setting time

vi. Heat of hydration

vii. Loss of ignition

viii. Bulk density

ix. Specific gravity

2.1.2.1 Port land cement

Cement manufactured from chalk and clay which hardens under water and when hard

resembles Portland stone in colour. Portland cement is the most common type of cement in

general use around the world as a basic ingredient of concrete, mortar, stucco, and non-

specialty grout. It was developed from other types of hydraulic lime in England in the early

19th century by Joseph Aspdin, and usually originates from limestone. It is a fine powder,

produced by heating limestone and clay minerals in a kiln to form clinker, grinding the clinker,

and adding 2 to 3 percent of gypsum. Several types of Portland cement are available. The most

common, called ordinary Portland cement (OPC), is grey, but white Portland cement is also

available. Its name is derived from its resemblance to Portland stone which was quarried on

the Isle of Portland in Dorset, England. It was named by Joseph Aspdin who obtained a patent

for it in 1824. However, his son William Aspdin is regarded as the inventor of "modern"

Portland cement due to his developments in the 1840s[2].

2.1.2 Sand

Sand is a granular material composed of finely divided rock and mineral particles. It is defined

by size, being finer than gravel and coarser than silt. Sand can also refer to a textural class of

soil or soil type i.e., a soil containing more than 85 percent sand-sized particles by mass. The

composition of sand is highly variable, depending on the local rock sources and conditions, but

the most common constituent of sand in inland continental settings and non-tropical coastal

settings is silica (silicon dioxide, or SiO2), usually in the form of quartz.

The second most common form of sand is calcium carbonate, for example aragonite, which has

mostly been created, over the past half billion years, by various forms of life, like coral and

shellfish. It is, for example, the primary form of sand apparent in areas where reefs have

dominated the ecosystem for millions of years like the Caribbean [3].

Fig 2.2 Ravi Sand](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-15-320.jpg)

![7

2.1.2.1 Composition

In terms of particle size as used by geologists, sand particles range in diameter from 0.0625

mm (or 1⁄16 mm) to 2 mm. An individual particle in this range size is termed a sand grain.

Sand grains are between gravel (with particles ranging from 2 mm up to 64 mm) and silt

(particles smaller than 0.0625 mm down to 0.004 mm). The size specification between sand

and gravel has remained constant for more than a century, but particle diameters as small as

0.02 mm were considered sand under the Albert Atterberg standard in use during the early 20th

century. A 1953 engineering standard published by the American Association of State

Highway and Transportation Officials set the minimum sand size at 0.074 mm. 1938

specification of the United States Department of Agriculture was 0.05 mm. Sand feels gritty

when rubbed between the fingers (silt, by comparison, feels like flour).

The most common constituent of sand, in inland continental settings and non-tropical coastal

settings, is silica (silicon dioxide, or SiO2), usually in the form of quartz, which, because of its

chemical inertness and considerable hardness, is the most common mineral resistant to

weathering[4].

2.1.3 Aggregate

Construction aggregate are simply aggregate is a broad category of coarse Particulate material

used in construction including sand, gravel, crush, stone etc. Course aggregate; Coarse

aggregates are particles greater than 4.75mm, but generally range between 9.5mm to 37.5mm

in diameter. They can either be from Primary, Secondary or Recycled sources. Primary, or

'virgin', aggregates are either Land- or Marine-Won. Gravel is a coarse marine-won aggregate;

land-won coarse aggregates include gravel and crushed rock. Gravels constitute the majority

of coarse aggregate used in concrete with crushed stone making up most of the remainder.

Secondary aggregates are materials which are the byproducts of extractive operations and are

derived from a very wide range of materials.

Fig 2.3 Coarse Aggregate](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-16-320.jpg)

![8

2.1.3.1 Coarse Aggregate

Coarse aggregates are larger size filler materials in construction. Coarse aggregates are the

particles that retain on 4.75 mm sieve. The surface area of coarse aggregate is less than fine

aggregates. Coarse aggregate acts as inert filler material for concrete. Coarse aggregates are

mainly used in concrete, railway track ballast, etc.

Fig 2.4 Coarse Aggregate

2.1.3.2 Fine aggregate

Fine aggregates are small size filler materials in construction. Fine aggregates are the particles

that pass through 4.75 mm sieve and retain on 0.075 mm sieve. The surface area of fine

aggregates is higher. The voids between the coarse aggregate are filled up by fine aggregate.

Fine aggregates are used in mortar, plaster, concrete, filling of road pavement layers, etc[5].

2.1.4 Bricks

Bricks are blocks of clay that have been hardened through being fired in a kiln or dried in the

sun. Over time, kiln-fired bricks have grown more popular than sun dried bricks, although both

are still found world widen the past, bricks came in many different shapes and sizes, but

today’s modern bricks tend to be a standard size or around 9'' × 4.5'' ×3''.](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-17-320.jpg)

![10

2.1.4.2.3 Third Class Bricks

These are not burnt so fully as in previous two cases but are generally of uniform reddish

yellow color. Its compressive strength lies between 35 – 70 kg/cm2 and absorption between 22

– 25 percent.

Use: They are used mostly in the ordinary type of construction and in dry situations.

2.1.4.2.4 Fourth Class Bricks

These types of bricks are irregular in shape and dark in color which is due to over burning.

They are quite strong in compressive strength, generally above 150 kg/cm2 and low in porosity

and absorption.

Use: They are, however, very commonly used in a broken form, in road construction,

foundations and floors as a coarse aggregate material[6].

2.1.4.3 Advantages of Bricks

i.The use of material such as bricks can increase the thermal mass of a building.

ii.Most types of masonry typically will not require painting and so can provide a structure with

reduced life-cycle costs.

iii.Masonry is very heat resistant and thus provides good fire protection.

iv.Masonry walls are more resistant to internshipiles, such as debris from hurricanes or

tornadoes.

v.Masonry structures built in compression preferably with lime mortar can have a useful life of

more than 500 years as compared to 30 to 100 for structures of steel or reinforced concrete.

2.1.4.4 Disadvantages of Bricks

i. Extreme weather causes degradation of masonry wall surfaces due to frost damage.

ii. This type of damage is common with certain types of brick, though rare with concrete.

2.1.5 Blocks

i. Masonry tends to be heavy and must be built upon a strong foundation, such as reinforced

concrete, to avoid settling and cracking.

ii. Save for concrete, masonry construction does not lend itself well to mechanization, and

requires more skilled labor than stick-framing.](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-19-320.jpg)

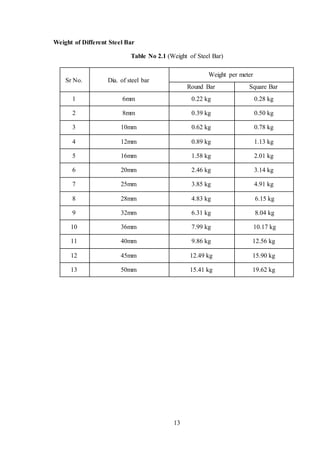

![14

Chapter 3 - Skill Attained

3.1 Test Performed on Aggregates

3.1.1 Sieve Analysis Test

To determine the particle size distribution of fine and coarse aggregates by sieving as per IS:

2386 (Part I) - 1963.By passing the sample downward through a series of standard sieves, each

of decreasing size openings, the aggregates are separated into several groups, each of which

contains aggregates in a particular size range. A set of IS Sieves of sizes - 80mm, 63mm,

50mm, 40mm, 31.5mm, 25mm, 20mm, 16mm, 12.5mm, 10mm, 6.3mm, 4.75mm, 3.35mm,

2.36mm, 1.18mm, 600µm, 300µm, 150µm and 75µm . Balance or scale with an accuracy to

measure 0.1 percent of the weight of the test sample.

The test sample is dried to a constant weight at a temperature of 110+5 o C and weighed. The

sample is sieved by using a set of IS Sieves. On completion of sieving, the material on each

sieve is weighed. Cumulative weight passing through each sieve is calculated as a percentage

of the total sample weight. Fineness modulus is obtained by adding cumulative percentage of

aggregates retained on each sieve and dividing the sum by 100 [7].

3.1.2 Water Absorption Test

To determine the water absorption of coarse aggregates as per IS: 2386 (Part III) - 1963.Wire

basket - perforated, electroplated or plastic coated with wire hangers for suspending it from the

balance. Water-tight container for suspending the basket. Dry soft absorbent cloth - 75cm x

45cm (2 nos.).Shallow tray of minimum 650 sq.cm area. Air-tight container of a capacity

similar to the basket. Oven. A sample not less than 2000g should be used.

The sample should be thoroughly washed to remove finer particles and dust, drained and then

placed in the wire basket and immersed in distilled water at a temperature between 22 and 32

o C. After immersion, the entrapped air should be removed by lifting the basket and allowing it

to drop 25 times in 25 seconds. The basket and sample should remain immersed for a period of

24 + ½ hrs. afterwards. The basket and aggregates should then be removed from the water,

allowed to drain for a few minutes, after which the aggregates should be gently emptied from

the basket on to one of the dry clothes and gently surface-dried with the cloth, transferring it to

a second dry cloth when the first would remove no further moisture. The aggregates should be

spread on the second cloth and exposed to the atmosphere away from direct sunlight till it

appears to be completely surface-dry. The aggregates should be weighed (Weight 'A'). The

aggregates should then be placed in an oven at a temperature of 100 to 110 o C for 24hrs. It

should then be removed from the oven, cooled and weighed (Weight 'B').

3.2 Test Performed on Concrete

3.2.1 Rebound Hammer Test

To assess the likely compressive strength of concrete by using rebound hammer as per IS:

13311 (Part 2) - 1992. The rebound of an elastic mass depends on the hardness of the surface

against which its mass strikes. When the plunger of the rebound hammer is pressed against the

surface of the concrete, the spring-controlled mass rebounds and the extent of such a rebound

depends upon the surface hardness of the concrete. The surface hardness and therefore the

rebound is taken to be related to the compressive strength of the concrete. The rebound value is](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-23-320.jpg)

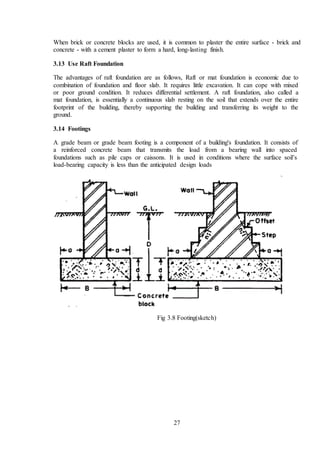

![23

Fig 3.4 Foundation (Pic 2)

3.7.3.1 Types of foundation

Foundation of building as the name implies is the starting of a building construction on site

really. Types of building, nature of soil and environmental conditions are the major

determinant of type of foundation you will use for your building.[8].

i. Strip foundation

ii. Pad foundation

iii. Raft foundation

iv. Pile foundation

3.7.3.1.1 Strip foundation

This is the most common type, it is mainly used where you have strong soil base and non-

waterlogged areas. Most small buildings of just a floor are constructed with this type of

foundation. Depends on the structural engineers recommendation, the depth of your foundation

could be from 600mm to 1200mm mostly for small scale buildings. When the soil is

excavated, a level at which the concrete will settle evenly is established, then concrete is

poured this may be from 150mm(6”) thick to 450mm(18”) thick depending also on building

after that block is set round the trenches at the center of foundation ,the foundation usually

follows the block lines. The blocks are then laid to D.P.C level before another concrete is

poured on top, this is the German or over site concrete. This type seems to be the cheapest.](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-32-320.jpg)

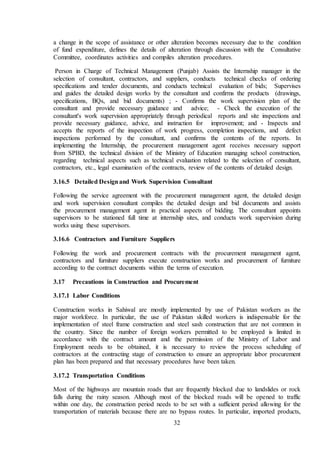

![25

3.8 Back Fill

To refill an excavation unit to restore the former ground surface and or to preserve the unit and

make it recognizable as have been excavated.

Fig 3.6 Back Fill (Pic 1)

Fig 3.7 Back Fill (Pic 2)

3.9 Water Stopper

Water Stops are flexible Plastic strips which provide a physical barrier to Water at concrete

joints, mostly in basements, Water retaining structures like Water tanks, Swimming pools,

structural foundations & other below ground level constructions. Water stops are also termed

as Water Bars, seals construction joints[9].](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-34-320.jpg)

![26

3.10Waterproofing

Waterproofing protects structures against water infiltration which can cause expensive and

irreversible damage. Waterproofing is the process of making an object or structure waterproof

or water-resistant so that it remains relatively unaffected by water or resisting the ingress of

water under specified conditions. Such items may be used in wet environments or underwater

to specified depths.

Water resistant and waterproof often refer to penetration of water in its liquid state and

possibly under pressure, whereas damp proof refers to resistance to humidity or dampness.

Permeation of water vapor through a material or structure is reported as a moisture vapor [10].

3.11Pile Foundation

Pile is a slender member with small area of cross-section relative to its length. They can

transfer load either by friction or by bearing. Pile foundation are used when:

i.The load is to be transferred to stronger or less compressible stratum, preferably rock.

ii.The granular soils need to be compacted.

iii.The horizontal and the inclined forces need to be carried from the bridge abutments and

the retaining walls[11].

3.11.1 Classification of Pile Foundation

The pile foundation can be further classified into following types on various basis such as

function, material, and method of installation which are listed below.

3.11.1.1 Basedon Function

i.Bearing piles

ii.Friction piles

iii.Combined piles (Both bearing and friction)

3.11.1.2 Basedon Material

i.Timber piles

ii.Concrete piles

iii.Steel piles

3.11.1.3 Basedon Method of Installation

i.Large displacement piles

ii.Small displacement piles

iii.Non-displacement piles

3.12Walls in concrete frame buildings

Concrete frame structures are strong and economical. Hence almost any walling materials can

be used with them. The heavier options include masonry walls of brick, concrete block, or

stone. The lighter options include drywall partitions made of light steel or wood studs covered

with sheeting boards. The former are used when strong, secure, and sound-proof enclosures are

required, and the latter when quick, flexible lightweight partitions are needed.](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-35-320.jpg)

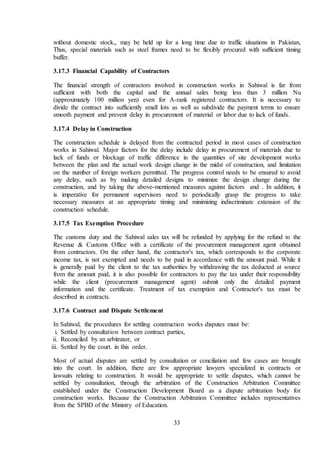

![28

Fig 3.9 Footing (Pic)

3.14.1 Benefits of Footing Foundation

i.They provide a level surface upon which to build the foundation.

ii.Also, they provide resistance to the upward-acting forces of the soil opposing the

downward-acting forces of the weight above.

iii.With widths greater than the foundation itself, footings serve to distribute the building load

to the soil.

iv.Footings add strength to the foundation system in weak or expanding soils. Shifting soils

push on foundation walls above the footing and laterally.

v.Footings can help absorb the pressure and shore up the foundation against unstable earth.

vi.Footings allow the foundation to be sunk far enough below grade to avoid frost depths where

heaving and thawing also cause uneven settlement.

In summary, footings help prevent foundations from sinking or buckling. They also help the

foundation remain perpendicular to the ground, and keep tall buildings upright. Of the many

possibilities for footings, reinforced concrete can underpin the foundation in two styles[12].

3.15 Tools & Plants

The tools that construction workers use

3.15.1 Safety Equipment

According to the Bureau of Labor Statistics.

3.15.2 Hand Tools

For simple jobs, construction workers will use hand tools such as a hammer.](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-37-320.jpg)

![29

3.15.3 Trucks

To carry equipment and supplies from one place to another.

3.15.4 Air Compressor

A two-stage air compressor is often used at job sites for pneumatic tool

3.15.5 Compactor

Compactor is used to compact soft soil. It consist on simple vibrator and small petrol engine.

The function is vibrator to reduce air from soft soil for batter load bearing.

Fig 3.10 Compactor

3.15.6 Excavator

Excavators are heavy construction equipment consisting of a boom, dipper, bucket and cab on

a rotating platform known as the "house". The house sits atop an undercarriage with tracks or

wheels. They are a natural progression from the steam shovels and often mistakenly called

power shovels. All movement and functions of a hydraulic excavator are accomplished

through the use of hydraulic fluid, with hydraulic cylinders and hydraulic motors. Due to the

linear actuation of hydraulic cylinders, their[13].](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-38-320.jpg)

![30

Fig 3.11 Excavator

3.15.7 Concrete Mixer

A concrete mixer is a device that homogeneously combines cement, aggregate such as sand or

gravel, and water to form concrete. A typical concrete mixer uses a revolving drum to mix the

components. For smaller volume works, portable concrete mixers are often used so that the

concrete can be made at the construction site, giving the workers ample time to use the

concrete before it hardens. An alternative to a machine is mixing concrete by hand[14].

Fig 3.12 Concrete Mixer (Pic 1)](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-39-320.jpg)

![36

technical work, data collection/analysis and technical documents preparation processes.The

training is an important course because it closes the gap between the scientific study and

practical study. Learning you how to deal with other. Finding that team work is the most

important element in every successful project. Learned you that the civil engineer is capable of

a lot of work such as supervision, implementation, the calculation of quantities and design

engineering apprentice engineer and in the future can work as a consultant and contractor.

Learning you how to control & manage the site and how behaves when their problems by take

a professional decision. Plans must be clear and easy to read for those who used. Successful

engineer will find the economic design and the project is implemented less time. The site

engineer responsibility to make sure that everything is right on schedule and every member is

doing on the right way.

4.3 Recommendation

Most works in the site needs careful attention and successive supervision of works but the in

some case the site works goes improperly due to different causes. This kind of carelessness is

not good for ether the consultant or the contractor. Therefore I suggest supervisors and site

engineers to take a care full look after the work executed on the site and the work that will be

executed. In the site there are works which is performed in the way that not to be performed.

Such works lids to safety problem, loose of human power if its degree is high and economy if it

is ordered to demolish it. Thus I recommend for the company the following. 1st of all level all

the constructed area according to the drawing level. Testing of material before it delivered to

the site and after it delivered and also when it is in use for construction. It is better to use steel

form work than wood (plywood) formwork as it is very repetitively used, stiff, and not

flammable easily and removed easily without damaging the concrete structure. A cover

material could be used for curing for any casted concrete structure until it attains its strength.

References

[1]Rodgers, Lucy (17 December 2018). "The massive CO2 emitter you may not know

about". BBC News. Retrieved 17 December 2018.

(6:30 pm , 03-06-20)

[2]ourland, Robert (2011). Concrete planet : the strange and fascinating story of the world's

most common man-made material. Amherst, N.Y.: Prometheus Books. ISBN 978-1616144814.

Retrieved 28 August 2015.

(8:30 am , 08-06-20)

[3] Glossary of terms in soil science (PDF). Ottawa: Agriculture Canada. 1976.

p. 35. ISBN 978-0662015338.

(5:30 pm , 15-06-20)

[4]Urquhart, Leonard Church, "Civil Engineering Handbook" McGraw-Hill Book Company

(1959)

(2:30 pm , 22-06-20)

[5]https://civiltoday.com/civil-engineering-materials/aggregate/253-difference-between-fine-

and-coarse-aggregate

(10:40 am , 28-06-20)

[6]https://civilseek.com/types-classification-ofbricks/#:~:text=Building%20bricks%20may%20

be%20defined ,molding%2C%20drying%20and%20burning.%E2%80%9D](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-45-320.jpg)

![37

(8:25 pm , 04-07-20)

[7]PavementInteractive. GradationTest.(2007). http://pavementinteractive.org/index.php?title=

Gradation_Test

(9:55 pm , 12-07-20)

[8] Pakistan Environmental Protection Agency, Brick Kiln Units (PDF file) Archived 16 June

2007 at the Wayback Machine

(6:45 pm , 19-07-20)

[9]engineeringcivil.com/what-is-the-function-of-waterstops-in-joints-of-box-culverts-and-

drainage-channels.

11:30 am , 22-07-20)

[10]U.S. Department of Energy/Brookhaven National Laboratory (October 21, 2013). "Nano-

cone textures generate extremely 'robust' water-repellent surfaces". Science Daily.

Retrieved October 22, 2013

(12:45 pm , 29-07-20)

[11] Designing Buildings https://www.designingbuildings.co.uk/wiki/Substructure

(6:30 pm , 03-08-20)

[12] Weygandt; Kieso; Kimmel (2003). Financial Accounting. Susan Elbe. p. 6. ISBN 0-471-

07241-9.

(9:12 pm , 09-08-20)

[13]Compact Excavator Specifications and Comparisons

(7:35 pm , 12-08-20)

[14] Hunker, Henry L. (2000). Columbus, Ohio: A Personal Geography. Ohio State University

Press. pp. 196. ISBN 978-0-8142-0857-1.

(11:55 am , 15-08-20)

[15]Glick, Thomas F. Livesey, Steven John & Wallis, Faith (2005). Medieval Science,

Technology, and Medicine: An Encyclopedia. Routledge. ISBN 0415969301.

(1:30 pm , 18-08-20)

[16]Terzaghi, Karl; Peck, Ralph Brazelton; Mesri, Gholamreza (1996), Soil mechanics in

engineering practice (3rd ed.), New York: John Wiley & Sons, p. 386, ISBN 0-471-08658-4

(9:00 pm , 25-08-20)](https://image.slidesharecdn.com/sajidreportfinal1-210630121246/85/Building-report-final-46-320.jpg)