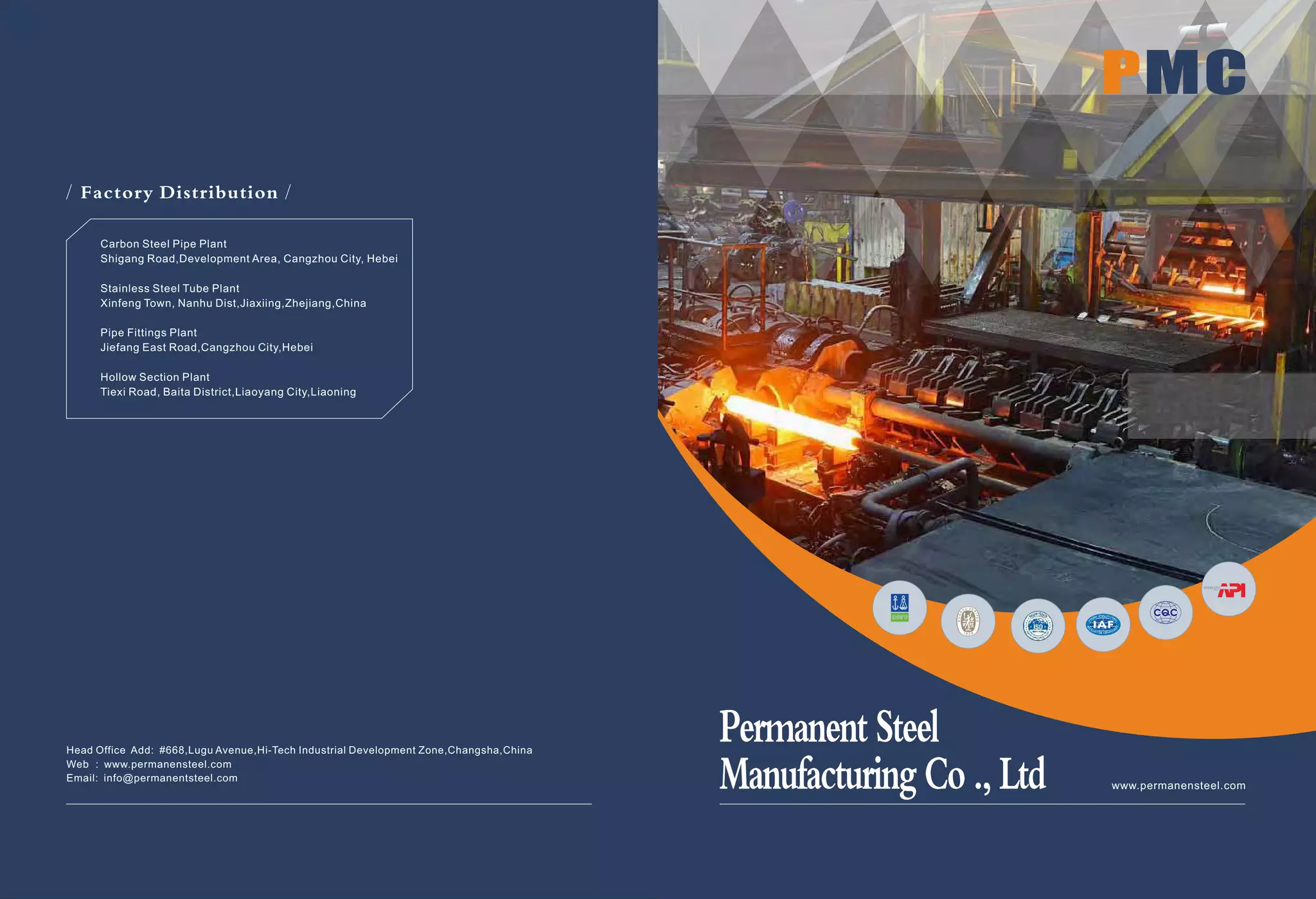

Permanent Steel Manufacturing Co., Ltd is a major supplier of carbon steel pipes, stainless steel tubes, and piping equipment, with a commitment to quality and customer satisfaction. The company operates advanced production facilities across multiple locations and adheres to strict quality and environmental management standards. Its wide product range complies with international standards and is designed to meet specific client requirements, reflecting its dedication to technical excellence and innovation.