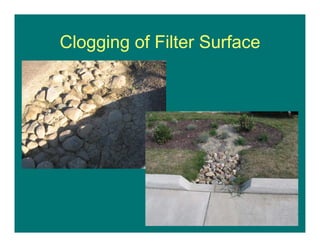

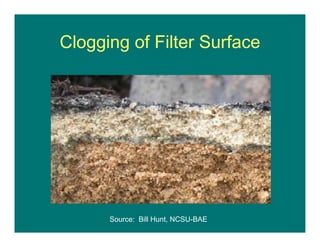

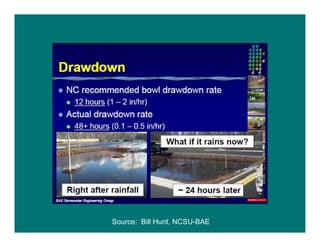

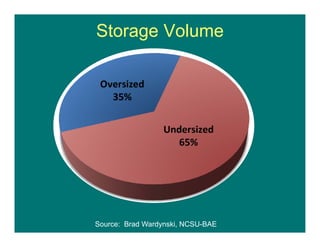

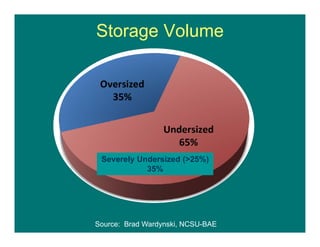

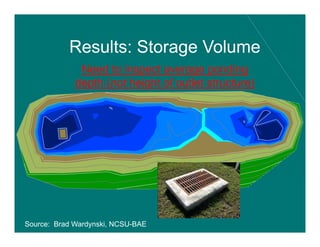

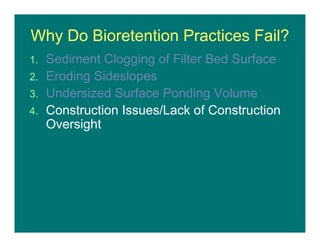

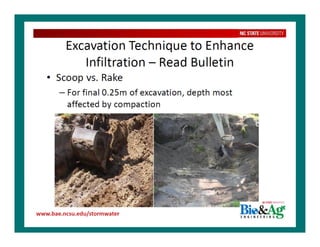

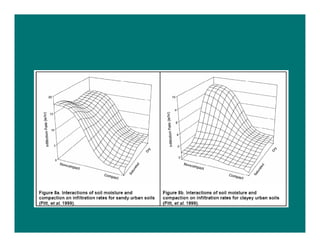

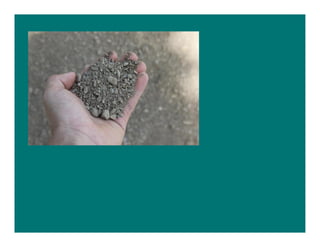

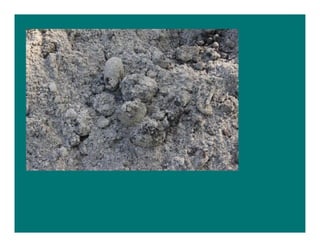

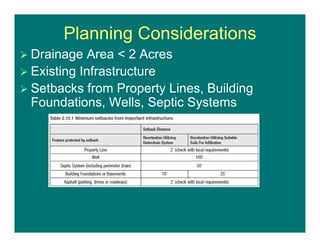

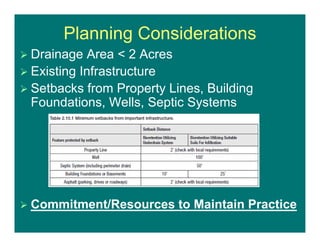

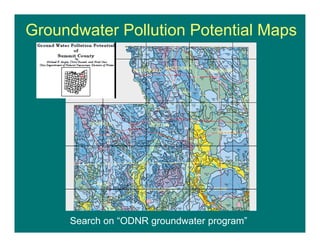

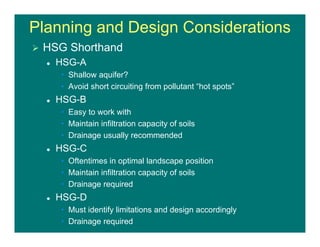

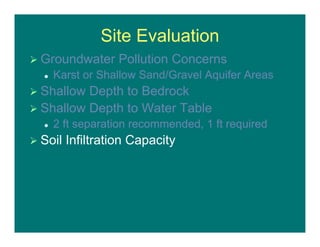

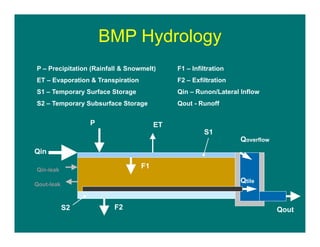

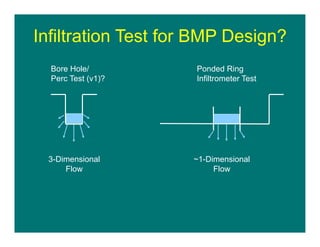

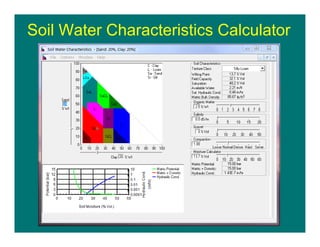

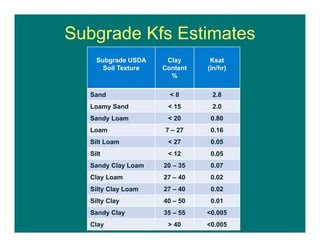

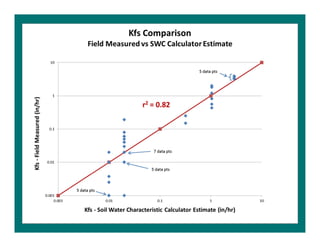

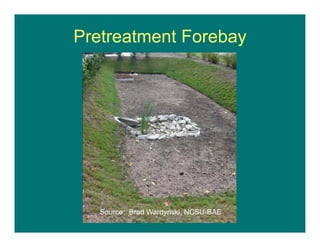

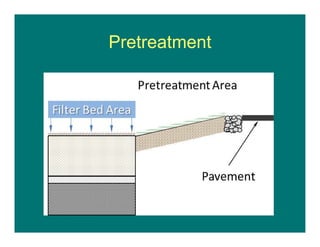

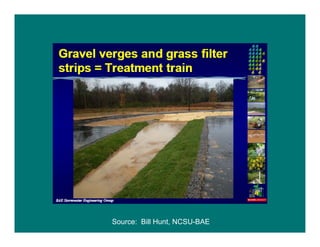

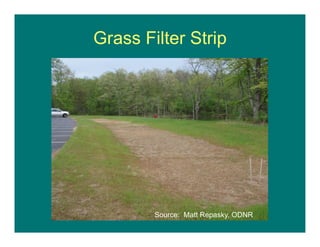

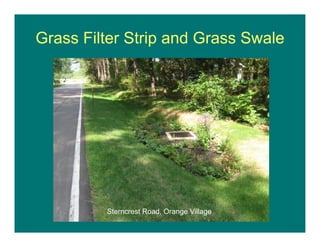

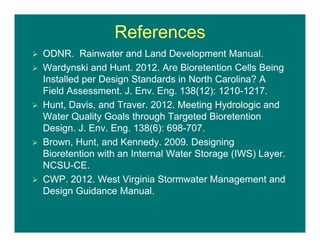

This document discusses reasons why bioretention practices fail and considerations for proper site evaluation and design. The top reasons for failure are sediment clogging, undersized cells due to overestimated infiltration, eroding sideslopes, and undersized ponding volumes. Other major causes are construction issues, poor plant selection and maintenance, and lack of pre-treatment. Proper site evaluation considers soil type, depth to bedrock/water table, and drainage area. Pretreatment is required to remove sediment before it reaches the bioretention cell.