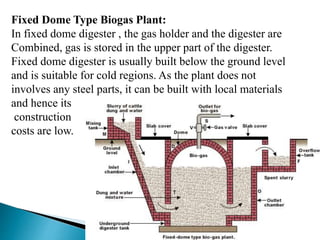

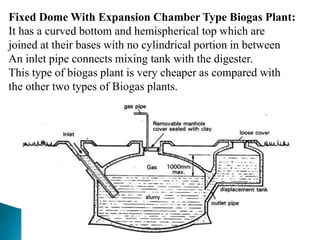

Pakistan faces an energy crisis as demand rises, but biogas can help meet rural energy needs. Biogas is a renewable resource that can be produced from agricultural waste like livestock manure and sugarcane bagasse. Pakistan has the potential to generate thousands of megawatts of power from biogas, helping its large rural population and reducing foreign exchange spent on fossil fuel imports. There are different types of biogas digesters that convert biomass into a gas that is mostly methane through anaerobic digestion. The government aims to install hundreds of thousands of domestic biogas plants but more support is needed to promote this sustainable technology.