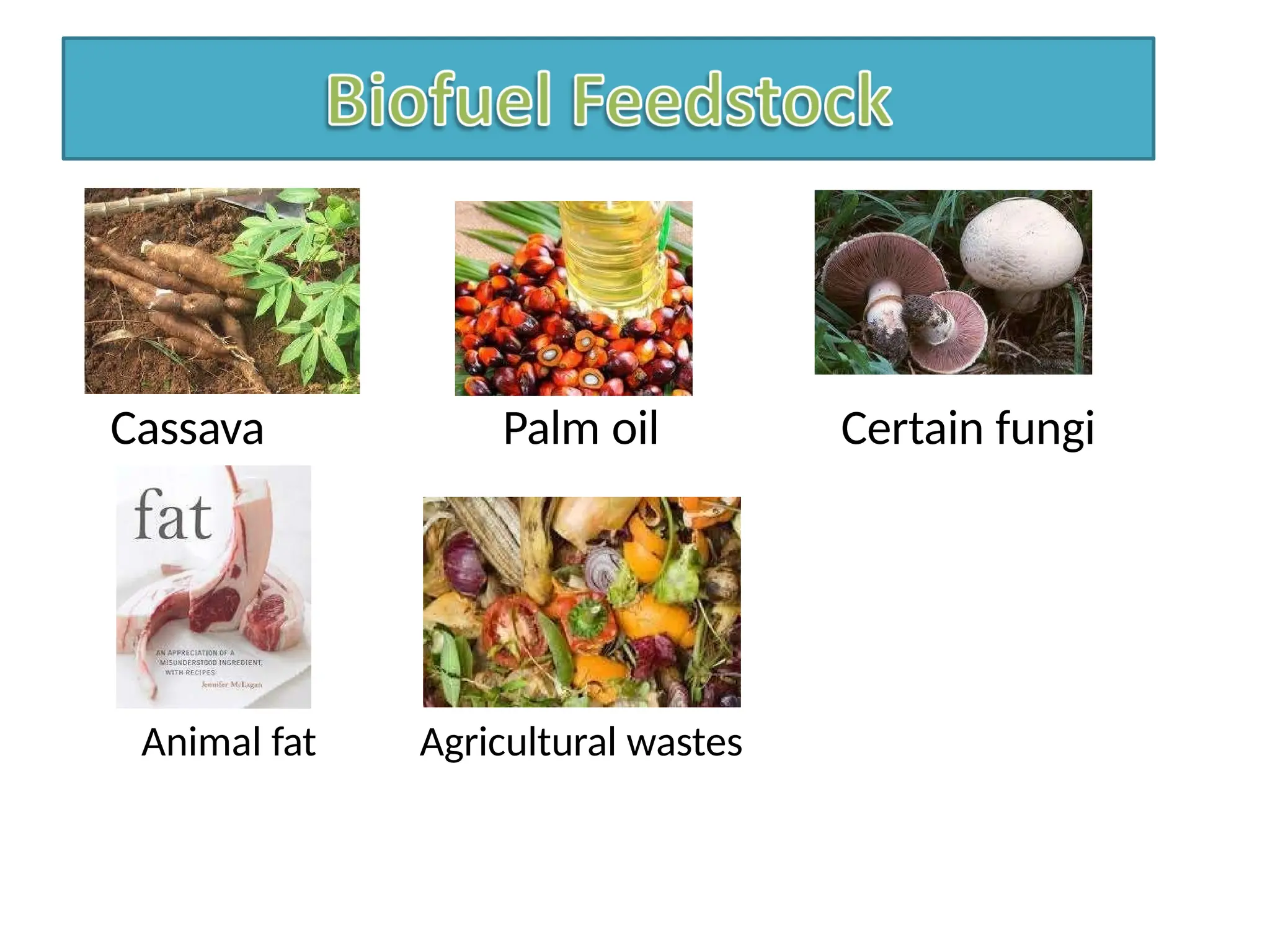

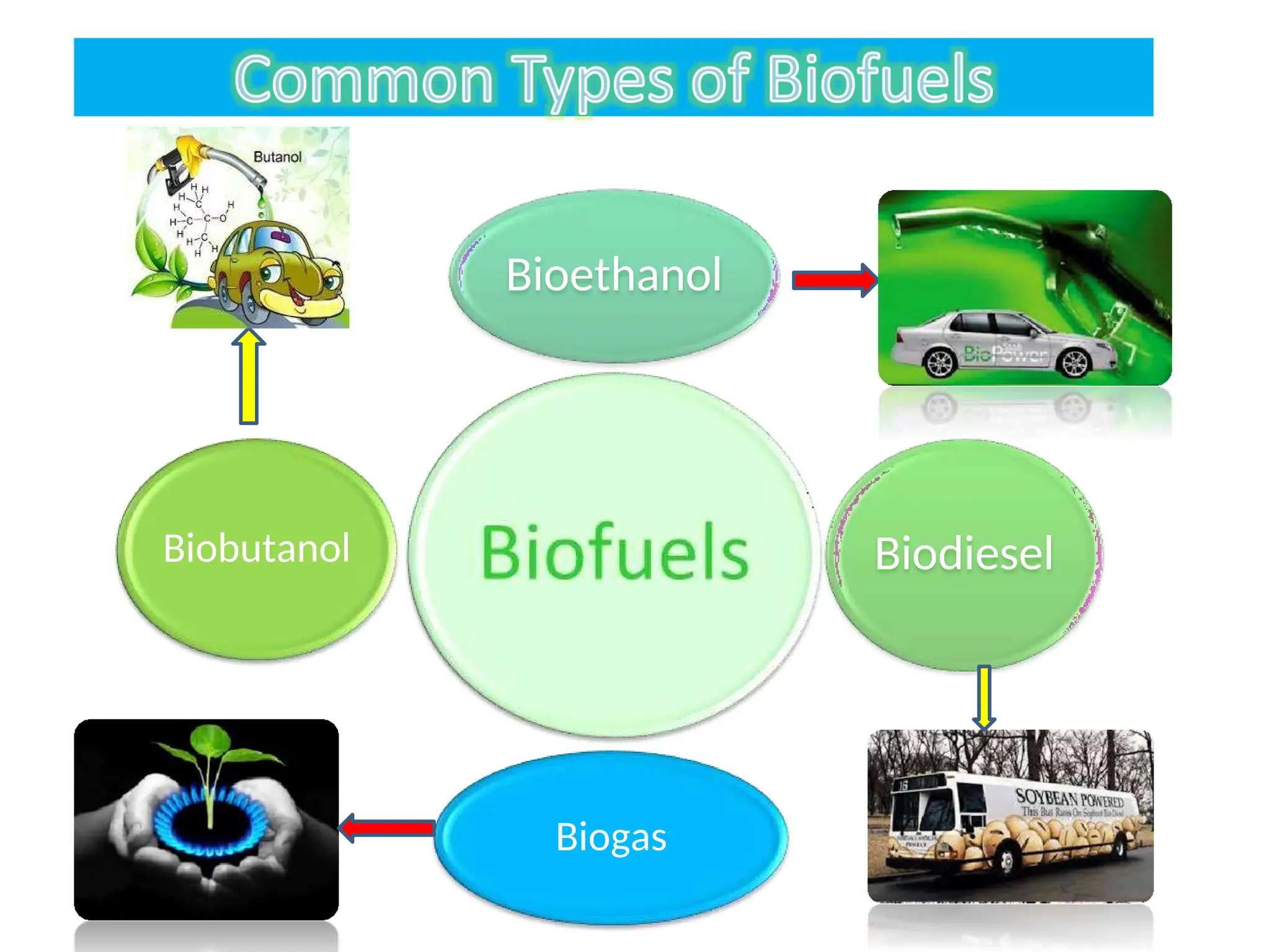

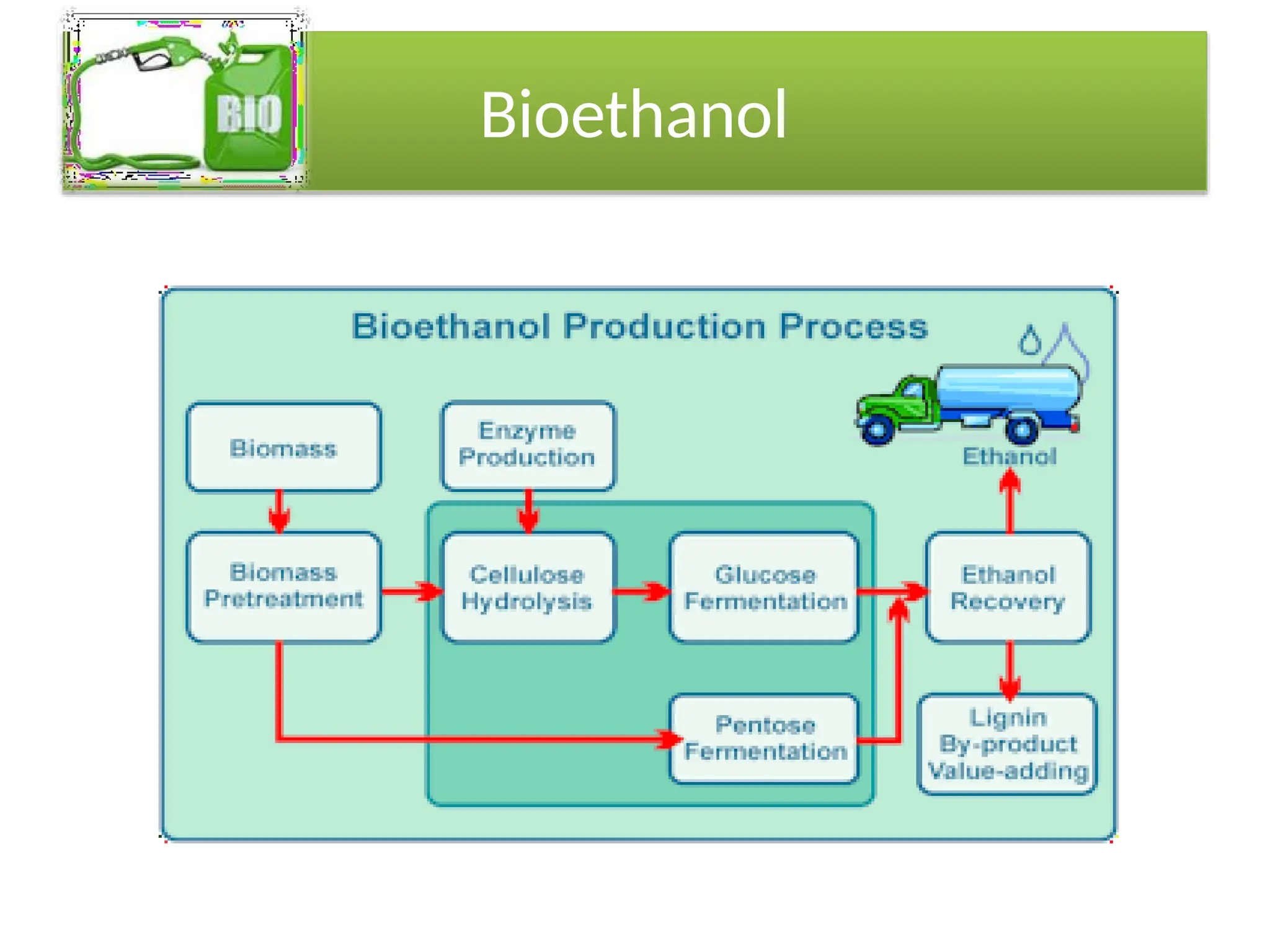

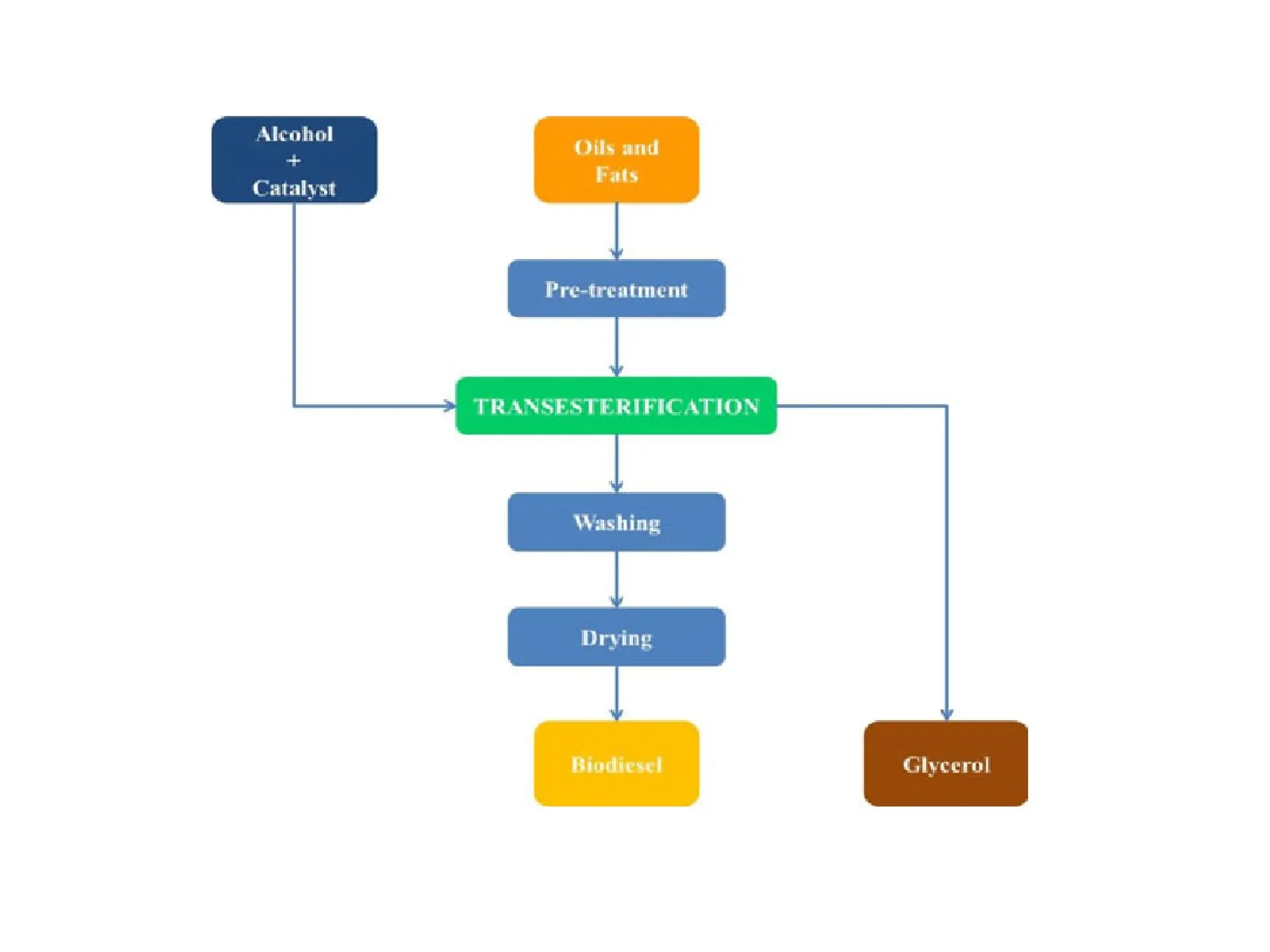

The document discusses biofuels, including their introduction, feedstocks, classification, production processes, and pros and cons. It highlights key types such as bioethanol, biodiesel, and biogas, and covers their historical development and environmental impacts. The advantages of biofuels include renewability and reduced greenhouse gas emissions, while disadvantages include high production costs and potential food shortages.