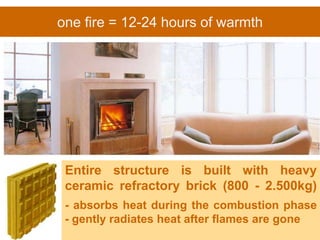

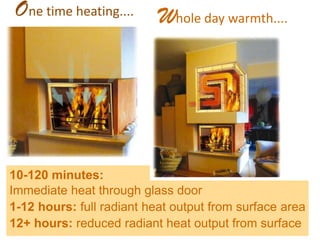

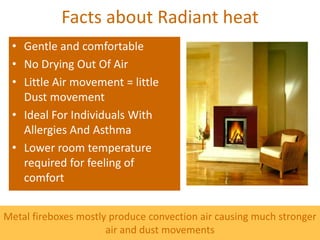

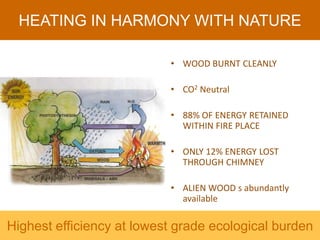

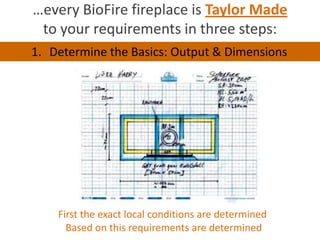

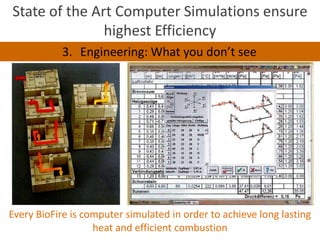

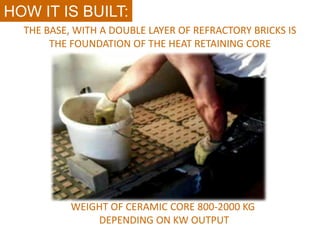

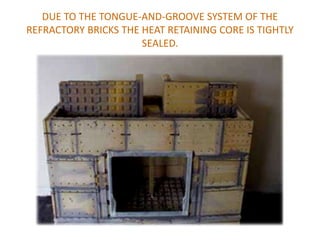

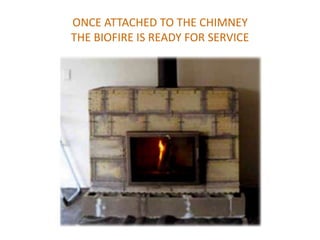

BioFire fireplaces provide 12-24 hours of warmth from one fire due to their heavy ceramic refractory brick construction that absorbs heat during combustion and slowly radiates it afterwards. They have the highest burning temperature of 1000°C for complete combustion and very low emissions. Radiant heat from the surface is gentle, comfortable heating without drying the air or causing much dust movement, making them suitable for allergy and asthma sufferers. Each BioFire is custom designed and engineered to maximize efficiency.