Batch Profile VLFM-05 (1).pptx

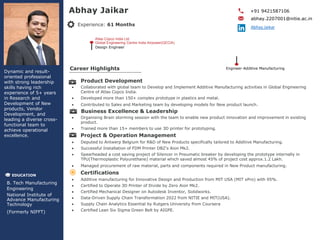

- 1. Experience: 61 Months Career Highlights Abhay Jaikar Dynamic and result- oriented professional with strong leadership skills having rich experience of 5+ years in Research and Development of New products, Vendor Development, and leading a diverse cross- functional team to achieve operational excellence. +91 9421587106 abhay.2207001@nitie.ac.in Abhay.Jaikar EDUCATION B. Tech Manufacturing Engineering National Institute of Advance Manufacturing Technology (Formerly NIFFT) Product Development Collaborated with global team to Develop and Implement Additive Manufacturing activities in Global Engineering Centre of Atlas Copco India. Developed more than 150+ complex prototype in plastics and metal. Contributed to Sales and Marketing team by developing models for New product launch. Business Excellence & Leadership Organising Brain storming session with the team to enable new product innovation and improvement in existing product. Trained more than 15+ members to use 3D printer for prototyping. Project & Operation Management Deputed to Antwerp Belgium for R&D of New Products specifically tailored to Additive Manufacturing. Successful Installation of FDM Printer DBZ’s Aion Mk2. Spearheaded a cost saving project of Silencer in Pneumatic breaker by developing the prototype internally in TPU(Thermoplastic Polyurethane) material which saved almost 45% of project cost approx.1.2 Lakh. Managed procurement of raw material, parts and components required in New Product manufacturing. Certifications Additive manufacturing for Innovative Design and Production from MIT USA (MIT xPro) with 95%. Certified to Operate 3D Printer of Divide by Zero Aion Mk2. Certified Mechanical Designer on Autodesk Inventor, Solidworks. Data-Driven Supply Chain Transformation 2022 from NITIE and MIT(USA). Supply Chain Analytics Essential by Rutgers University from Coursera Certified Lean Six Sigma Green Belt by AIGPE. Atlas Copco India Ltd. Global Engineering Centre India Airpower(GECIA) Design Engineer Engineer-Additive Manufacturing

- 2. Supply Chain Management • Monitoring & managing the entire warehousing operations across 12 manufacturing and project sites of RIL. • Monitor stock transfer orders among the manufacturing and project warehouses. • Drive change management initiatives across 24 manufacturing and project warehouses of RIL. • Managed product stakeholder engagement with internal customer onboarding and feedback for continuous improvements. Project Management • Led integration, implementation & stabilization of SAP EWM with SAP IM across 12 project warehouses at RIL. • As a representative of material management CoE, led project plant inventory migration to a new server. • Integration, implementation & stabilization of QR-code embedded SAP EWM with SAP IM across 2 out of12 manufacturing site warehouses. • Responsible for process enhancement, designing, and UAT for QR-based end-to-end transactional automation on mobility devices at manufacturing sites of Reliance. • Increase end-user uptake of new tools through workshops, training, and user manual/SOP creation • Implemented vacuum packaging process across manufacturing warehouses to improve the shelf life of spares. • Collaborated with a vendor to develop an indigenous PPE kiosk for installation at various mfg. locations at RIL sites. Project Management: J3 • Spearheaded the CPU plant’s project activities from scratch till handing over to operation and maintenance. • Executed 1000MT+ heavy erections of super structures and structural steel modules for five units. • Drafted & compiled structural & piping progress reports, constraints & front available for the planning department. • Manage and direct contractor employees to keep things running smoothly and increase productivity. Certifications • Data-Driven Supply Chain Transformation 2022 from NITIE and MIT(USA). Reward and Recognition • Recognized as an excellent performer for years 2018, 2019 & 2021. Extracurricular • Planned & Organized all Site Materials conferences at Silvassa (2018-19) & at Hoshiarpur (2019-20). Experience: 106 Months Career Highlights Aditya Singh Chauhan Manager, CoE Material Management Reliance Industries Limited Aditya.Chauhan +91 7016900362 aditya.2207002@nitie.ac.in Reliance Industries Limited Project Engineer, RPMG An adaptable and steadfast professional with 8.8 years of work experience in Materials Management, Project Management, Process Designing & Stakeholder Management, and Performance Improvement. Reliance Industries Limited Senior Manager, CoE Material Management Reliance Industries Limited GET, RPMG Education B.E. Mechanical Acropolis Inst. of Technology & Research Indore

- 3. Continuous Improvement • Conducting programs like training of trainers & assessors to bridge the gap in the skilling ecosystem. • Coordinate with the Line Ministries (Department of Heavy Industries) and National Skill Development Council for the Development of Qualification Packs in the Capital Goods Sector. • Technical expertise in metallurgical failure analysis of Diesel Engine Components manufactured by BOSCH. Policy Advisory • Assessment of startup applications, including drafting recommendations for cases to be presented to the Inter- ministerial Board Secretariat of Start Up India. • Organizing Stakeholder consultation for the reforms done by the Boiler Division for Ease of Doing Business. Leadership • Managed a team of 7 process technicians, ensuring process control & overall quality, including physical inspection of Rolled Products (Hot Rolled Finished Coils, Hot Rolled Plates, Cold Rolled Products). • Technology mapping for strategic collaboration between National laboratories & industries to ensure innovative offerings for the industries through technology transfer. • Project Management • Member of Project Monitoring Committee for the release of IOCL Start Up Corpus Fund of Rs 30 Crore for 11 startups by managing and monitoring the process milestones set for the startups. • Executed Six-sigma project for ‘reduction in internal inspection rejection for cold rolled products by 10%'. Certifications • Lead Auditor for ISO 9001:2015 by Bureau Veritas. • ‘Patent Law for Engineers and Scientists’ from IIT Madras, NPTEL • 'Patent Drafting for Beginners’ from IIT Madras, NPTEL • Data-Driven Supply Chain Transformation 2022 from NITIE and MIT. Experience: 112 Months Career Highlights Amrita Verya Dynamic and result - oriented Professional with rich experience of more than 9 years in Skill Development, Policy Advisory, Project Management, Stakeholder Management and Quality Control. Senior Engineer, Quality Management and Methods NRDC, Delhi Technology Transfer Analyst BOSCH Limited,Nashik BALCO (Vedanta Resources), Korba Assistant Manager +91 9712981356 amrita.2207003@nitie.ac.in Amrita.Verya DPIIT, Delhi Young Professional CGSC, Delhi. Assistant Manager, Standards Education B.Tech – Metallurgical Engineering NIT, Raipur

- 4. Projects • New product development: Scorpio N (6R450) transmission housing machining • Successfully designed & implemented Low-Cost Automation (LCA) in Housing machining line – Pneumatic motors used for tightening of 6 bolts in one set up • Two Mahindra Yellow Belt Projects in F-2019 & F-2020 • Commissioning of CNC Bending Machine Industrial Engineering & Improvement • Long Term Settlement (LTS) 2022: OPP (Output Per Person) improvement from current 4.7 mph (miles/hr) to 5.21 mph (miles/hr) resulting into 12% rise in productivity • Saved conversion cost of Rs. 3.6 lakhs/annum by 2 Manpower saving per day in housing machining by clubbing 6 in 1 bolt tightener with Automated Guided Vehicle (AGV) Leadership • Team Leader in ‘i4 (ingenious, ideas, incubation & implementation) Conference 2021’. 2nd Runner up under ‘Accepting No Limit’ pillar of Mahindra Rise Philosophy • Drive Train Sub-System Head in Ethan Racing, which ranked 36th in Formula Student India (FSI) 2016 Operational Excellence • Machine JH (Jishu Hozen) Step up-gradation: Revisited till Step 5 for all machines and restored machines after Corona pandemic • Real-time problems solving with applications of techniques like Line balancing, layout optimization and VSM, Talor’s tool life, DOE to maintain & improve PQCDSM indicators. • Implemented Lean, 5S, TPM, Kaizens, Digitization: Online SPC & CLITA etc. methodologies in plant. Certifications • Mahindra Yellow Belt Certification • Data driven supply chain transformation by NITIE , IIT-BHU and MIT • CAB Leadership Behaviors (Collaborative, Agile, Bold Leadership Behavior Awareness Module) Harvard Manage Mentor Rewards & Recognitions • 4 Excellence Awards & 3 Spot Awards in Mahindra Rise Experience: 70 Months Career Highlights Aniket Mandavkar Highly motivated professional with 6 years of rich experience in the manufacturing, operations, logistics & industrial engineering domain from start-up to MNC Page 4 | Individual Profiles NITIE PGDEx-VLFM Placement Brochure 2021-22 A.M.: Transmission Gear & Shaft Line Mahindra Rise A.M.: Transmission Housing Mahindra Rise PharmEasy Logistic Executive G.A.T.: Foundry & Transmission Mahindra Rise Mahindra Rise A.M.: Transmission Housing, Industrial Engineering & Improvement Cell G-One Laser Tech Pvt. Ltd. Mechanical Engineer +91 9819252809 aniket.2207004@nitie.ac.in Aniket.Mandavkar Education B.E. Mechanical Mumbai University Diploma Mechanical V.J.T.I., Mumbai Experience: 72 Months

- 5. Strategic Sourcing & procurement • Part of strategic Sourcing team handled BIW, sheet-metal & forging parts procurement worth annual spend of INR 1600 Cr+ through Techno-Commercial feasibility analysis and Achieved significant Cost optimization by using Strategic negotiation techniques. • Partnered with global suppliers; Responsible for supplier selection, sourcing strategy development, supply condition finalisation, Cost Settlement & negotiations. Strategy & leadership • Designed Differentiated Sourcing strategy and finalized complete vendor portfolio for 2-wheeler, Construction equipment Sector & Auto Sector. • Monitored Supplier performance, Auditing & Assessment of new suppliers to mitigation of supplier Risk, Upgradation activity on the chronically poor Supplier • Spearheaded a digital transformation project by automating Blank Layout process. Project Management • Project Lead for High-Performance Bikes – Green field Project; collaborated with multiple stakeholders, managed Model Development Cycle, Led development of 350+exclusive parts. Project cost estimation, Business case preparation & enabled timely proto part submission. • Driven digitization project through implementation of spend analytics tool-Qlik-sense; Enriched the Digital Database & analysed all the potential cost-saving ideas and implemented Feasible cases. Rewards and Certifications • Excellence Award by Business head for in-house space creation by out-Sourcing of Cabin fabrication. • Certificate of Appreciation for reducing IVC by 20% for C-class parts. • Global Digitization Supply chain by NITIE and MIT USA. Experience : 95 Months Career Highlights Anjali Jain A result-oriented & Self-motivated professional with 7.5+ years of experience in Strategic Sourcing & procurement with expertise in Vendor Management, Cost Optimisation, Negotiations, Stakeholder Management, Process improvement, Project Management , Data Analysis and Problem solving. Page 5 | Individual Profiles Hero MotoCorp Ltd. Mahindra & Mahindra Ltd. Assistant Manager +91 9950383471 anjali.2207005@nitie.ac.in Anjali.Jain Education B.Tech College of Tech & Engineering, MPUAT, Udaipur Assistant Manager Mahindra & Mahindra Ltd. Manager

- 6. Business Excellence & Quality Management • Administered PAN India Operations for Quality Management System and Auditing. Facilitated Two Plant Merging activity and Approved it from Toyota and Renault Nissan for Start of Production as a Brownfield Project. • Spearheaded the Development activity of Swift Seat Recliner Spring and Fuel Lid spring of Maestro Edge. • Developed and Implemented Corporate strategies for QMS and Auditing Function under one Umbrella for all units. • Conceptualized and Implemented of Integrated Manual for QMS,EMS and OHSMS in Plants. • Facilitated and Summarized MRM inputs from all Plant and Presented to Top Management. Digital Transformation & Process Improvement • Led Implementation of SAP S/4HANA in Continuous Manufacturing for PP,PM & QM Modules as CTM, resulting in a 20% reduction in Turnaround time for order Bundling. • Assisting for the Smart Manufacturing and Industry 4.0 (IIOT) implementation at the Pune facility. • Enhanced New Vendor Selection system and Development for Critical Components. • Carried out Quality Defect rejection by 6% by studying the Process capability and enhancing the Process Efficiency. • Demonstrated Training to Stakeholder for the Importance of OHS and QMS. Operational Excellence • Improved OEE by 7% by reducing Changeover time by 14% by Implementing Heijunka Production Planning. • Reduce cycle time by 18% by redesigning the material flow and reorganizing the layout with a 3S Map and a Value Stream Mapping. • Implemented Lean, 5S, TPM, Kaizens etc. methodologies in plant. • Reduced Critical Spare Inventory by 10% using ABC & VED analysis. Certifications • Six sigma Green Belt by Motorola. • Lead Auditor EMS and OHSMS by TUV-SUD and Certified Internal Auditor for ISO 9001:2015, AS9100D & IATF 16949:2016 by DNV-GL. • Certified For Automotive Core Tools PFMEA ,APQP,PPAP, MSA & SPC. Experience: 90 Months Career Highlights Ankit Saini Dynamic and Result oriented Professional with rich experience of 7+ years in Business Excellence, New Product Development, Quality Assurance (QA,QMS & SQA),Operational Excellence ,Stakeholder Management, and SAP Implementation. Engineer QMS & TPM Star Wire India Ltd. Emkay Auto. Ind. Ltd. Engineer QA & NPD Sr. Engineer QMS & SQA Mark Exhaust System Ltd Technico Industries Ltd. AM Business Excellence Education B. Tech Mechanical Engineering. Punjab Technical University +91 7888706235 ankit.2207006@nitie.ac.in Ankit.Saini

- 7. Strategic Procurement • Managed Procurement of both Project and Revenue Orders; both Material and Services. • Managed an overall spend of $25M; comprising of various stand-alone orders valuing $1M & achieving cost savings of 6.7%. • Conducted supplier profiling to Identify Strategic Suppliers and established Annual rate contracts with them to meet strategic business goals. • Partnered with global and domestic suppliers to build new products to enhance business parameters. Digital Transformation - Strategy & Product • Contributed in laying out Strategy to develop a new vertical under Procurement & Contracting umbrella. • As a Subject Matter Expert, contributed in the development of a digital product (RFX Manager); Involved in detailing Users Requirement, User Testing and Prioritizing New features. Operations Management • Spearheaded maintenance operations (mechanical) of petrochemical plant by planning and monitoring preventive and predictive maintenance activities and optimising resource utilization. • Conducted spares profiling & monitored Inventory levels whilst reducing equipment downtime. Leadership • Procurement SPOC for Project and Senior leadership team for ongoing Projects. • Spearheaded a Project “Replacement of Safety Valve” to enhance plant safety; Capex $1.1M and Quantum 248 Numbers. Rewards and Recognition • Conferred with R-Sammaan for Exceptional work performance and Ownership Mindset. Certifications • Legal Aspects of Contracting by XLRI. • Global Digitization of Supply chain by NITIE and MIT. Experience: 84 Months Career Highlights Armaan Gupta Result Oriented Supply Chain Professional with experience in both Technical and Business functions and specialization in Strategic Procurement, Transformation Strategy, Process and Business Excellence Education Thapar Institute of Engineering & Technology - Mechanical Engineering (2011 – 2015) Maintenance Engineer Reliance Industries Limited Procurement Manager Reliance Industries Limited Reliance Industries Limited Graduate Engineer Trainee +91 7020602669 armaan.2207007@nitie.ac.in Armaan.Gupta

- 8. Leadership Spearheaded cross-functional team of 45 people as section head of 6.15 MTPA mineral processing unit, responsible for the operation, inventory, safety, and manpower planning. Successfully maintained optimum plant inventory level through SAP MM Module. Led the dispatch section of stream-1 with maximum concentrate transportation and reduction of cycle time (loading and unloading). Imparted on-the-job training to the plant workforce on Dupont Industrial Safety standards (5S, near miss, and PTW), plant operation, and basic TQM tools. Digital Transformation Led the digitalization project of the advanced process control implementation in the stream-1 of HZL RAM Mill and acted as SPOC between HZL and MINTEC Team. PLC upgradation and stabilization of stream-1 of RAM HZL to improve the reliability of plant operation. Operational Excellence & Project Management Successfully led the six sigma project for the reduction of CuSO4 gpt from 923 to 798 for FY2021-22 which led to an annual saving of 3.78cr. Successful reduction in specific power consumption of 4kWh/MT by using single stage classification instead of the double stage in grinding circuit. Certifications Lean Six sigma green belt by Henry Harvin. Data-driven global Supply chain management by NITIE and MIT. Achievement V-reach tech leader award Experience: 73 Months Career Highlights Ashish Kumar Dynamic and Goal Oriented Professional with 6 years of experience in the manufacturing domain with specialization in Operation excellence, Project management, strategic planning, and inventory management. Hindustan Zinc Limited Graduate Engineer Trainee +91 7858869292 ashish.2207008@nitie.ac.in Ashish.Kumar Education B Tech. Metallurgical & Materials Engineering NIT Jamshedpur Hindustan Zinc Limited Associate Manager Hindustan Zinc Limited Process Engineer

- 9. Operations Management • Technical in-charge of a production pot line (Line 3, Room no.2). Responsible for managing a team of employees to ensure all operation, maintenance, safety etc. for the given production line • Periodic audit for subsequent preventive/corrective action for efficient flow of operational activities and production of high quality metal. Project Management • Digitization projects that targeted on introducing new technologies such as 3D printing, digitized SOP training system, cost reduction techniques through the digitization of operational activities etc. on the shopfloor. Data Analysis • Experiences in data analysis on excel for tracking of the performance of the main metal Units by tracking factors such as technical performance parameters, safety parameters, critical projects status, digitization projects, cost of production etc. • Analysis of the technical parameters performance trend and taking actions for increasing the efficiency of the operational activities, enhance the quality of the metal produced and reduce the specific power consumption of the process Marketing Management • Responsible for achieving the target sales numbers for the West customers, new customer onboarding and promote the concept of online sales amongst all the west region customers Certifications • Coursera Certification in Market research and Consumer behavior • Data-driven supply chain transformation by NITIE and MIT. Experience: 60 Months Career Highlights Debamita Chowdhuri A versatile, analytical and hardworking professional, with a practical “get the things done” approach with a work experience of 5 Years in Operations, innovation cell, data analysis and domestic sales marketing. Innovation Cell member Vedanta Aluminum Limited Technical Analyst Vedanta Aluminum Limited Vedanta Aluminum Limited Operations, Technical In-Charge +91 9916861603 debamita.2207009@nitie.ac.in Debamita.Chowdhuri Vedanta Aluminum Limited Area sales manager, Domestic sales EDUCATION:- B.Tech – Chemical Engineering - Manipal Institute of Technology

- 10. • • Managing the entire Supply Chain operation & planning activities in logistics & warehousing from central team. • Lead the monthly 1.2 cr shipments S&OP (Demand planning) to minimize the demand and supply gap in coordination with cross functional stakeholders. • Executed 7 lacs sq-ft warehouse operation & optimize shipment leakages to minimize upstream and downstream breaches. • Achieved 67% NPS of Flipkart & Myntra with respect to an average target NPS of 69% • Spearheaded cross-functional team of 40 people as planning coordinator of 1.2 MTPA steel plants production planning & control responsibility for the operation, inventory Management, safety, and manpower planning. Technology transfer & Data Analytics Intelligence • Technology transfer from Walmart to Flipkart for different demand planning models & new last mile process optimization by using in-house build SAAS like ( SAP, Oculus, Nucleus & Pluto). Worked closely with the design team to build inventory management & outbound planning, manpower planning for different warehouses. Successfully onboarded 3 warehouses from inception to live phase. Leadership • Leaded 42 pan India warehouses operation from central operation & planning team, Daily level escalation handling. Connected with top management for identifying the potential solution & accordingly enabled those solution on the ground Process Operations & engineering division Operational Excellence • Implemented Lean, 5S & Kaizens methodologies in plant & warehouses. • Optimized Inventory space up to 8% by using Machine Learning & ABC XYZ analysis. Executed dynamic merge area picklist creation concept for the customer-centric outbound operation to enhance the speed matrix. Maximize the unit level profitability by savings of approx. 78 lacs/monthly through data driving right supply procurement framework. Certifications & Recognition • DATA Science professional (Certified Great learning data scientist) • SCM Pro CII & Yellow belt certified logistics professional • Data-Driven Supply Chain Transformation by NITIE and MIT. • Best Employee award from central planning - "Flipstar Award'21" From CEO (Flipkart group of companies) Experience: 60 Months Debarpan Haldar A professional with 5+ years of diverse and in- depth experience across different functions of Supply Chain Management. Expertise in operation, Sales & Operational Planning, Analyst, Digitalization, Logistics Excellence and People Management Education B Tech , Metallurgical Engineering NIT Durgapur 9831803805 debarpan.2207010@nitie.ac.in Debarpan.Haldar 2017-2019 Career Highlights Supply Chain Management & Planning Blackbuck Logistics Logistics Manager Flipkart Internet Pvt Ltd. Dept Manager – Supply chain analyst Jindal Stainless Ltd. Associate Manager – PPC

- 11. Supply Chain Management • Executed lead time reduction project at DK-EPCOS India limited, reduced capacitors lead time from seven days to five days by analyzing and modifying process parameters. • Local development of spares for Kemper Germany make fume extraction filters which were developed in India with the help of UTH Filter’s corporation Nasik, India through strategic sourcing. Annual savings of 10 lacs. Leadership • Led a team of 100 technicians of Operation and plant engineering for a motor manufacturing plant at Godrej and Boyce. Ensured plant OEE, machine uptime, and zero breakdowns of plant machineries. • Circle leader for Planned maintenance(PM Pillar) at TDK-EPCOS Nasik also implemented TPM at ground level. Ensured up-skilling of subordinate teams through technical training and workshops, ensured the implementation of TPM, Lean Manufacturing, Kaizen culture. Technology Transfer • Technology transfer of Vacuum Impregnation technology from TDK Spain to TDK India. Executed designing, commissioning, and installation of the same. • Edwards make vane sump vacuum pumps upgraded to Leybold make dry air end Dryvac vacuum pump operating at 120HZ,7000 RPM. Certifications • Certified Automation Engineer from VIATA Academy, Nasik. • CAD certification from CADCAM GURU, Pune. Experience: 110 Months Career Highlights Dhananjay Patwari A goal oriented professional having 9.2 years experience in the manufacturing sector in operational excellence, cost saving kaizens, lead time and cycle time reduction projects, energy saving projects. Senior Engineer TDK-EPCOS India Ltd. Process Engineer Mahindra Sona Ltd. Graduate Engg. Trainee Godrej & Boyce Co Ltd. Assistant Manager +91 8554914044 dhananjay.2207011@nitie.ac.in Dhananjay.Patwari Education B.E (Mechanical) IIST,INDORE Hindustan National Glass Ltd

- 12. Process Improvement & Cost Optimization • Successfully managed the Quality of the Car body by achieving 94.8% CTQ PIST Accuracy & 99.88% Robotic Weld spot integrity for achieving Excellent Fit-Finish & NCAP Safety Rating of the Tiago and Tigor Model, respectively, by maintaining the process parameters like Data analysis of CMM-CF reports, Smartnet system reports and accordingly prepared the execution strategy. • Led the Patent registered innovative Automated Nugget peel-off test project, which has reduced 96% Man- hour involvement and 94% Process time of testing activity. • Reduction in vehicle-related issues to 28%(2021-22) received from the customer using the CAPA tool. • Led the project for Retrieval of Mastic sealant through which DMC cost was reduced by 38 Rs /car. Project Management • Led the Tata Tigor Electric vehicle project from the BIW team side in which DAP, Fixture buy-off, Alpha/Beta/PP/SOP, and Quality maturation were done by achieving 90% PIST accuracy. • Identified critical bottlenecks in the existing production line from the load chart and reduced the cycle time, and improved the JPH of the line by 18%. • “SparQplug” dashboard co-ordinator for Sanand Plant: All-in-one dashboard for insights into Production & Quality. • Inventory management of 472 Jig & fixtures spare. Leadership • Led a team of 3 Junior engineers, 8 Production operators, and 42 contractual workforces to run manufacturing quality-related activities to fulfill the business plan. • Trained semi-skilled, unskilled workforce on Industrial safety,5S, and Quality related tools. Rewards & Recognition • Tata Motors “Innovista” national level finalist in the category of “implemented innovations in core processes. Certification • Auto Electrical and Electronics Certification Course from Nirma University • Data-Driven Supply Chain Transformation by NITIE and MIT. Experience: 60 Months Career Highlights Dhruv Shah Decisive, Strategic and Performance driven professional with 5 years of experiance in Quality improvement, Operations Management, Project Management & Inventory management. Senior Manager-5.3 Tata Motors Limited Senior Manager-5.2 Tata Motors Limited Tata Motors Limited Graduate Engineer Trainee +91 9427756851 dhruv.2207012@nitie.ac.in Dhruv.Shah Education B.E.Mechanical M.S.University, Vadodara

- 13. Inventory & Warehousing • Monitoring & managing the entire warehousing activities across 12 manufacturing sites of RIL • Responsible for designing, developing, testing & implementing of inbound, inventory and outbound processes undertaken by the Material Management function for improvisation & simplification Strategic Projects • Designing & implementation of improved receipt process for shelf life managed material namely as-is shelf life entry in receipt, improvements in shelf life monitoring report, validations of shelf life in inbound process • Designing & implementation of the end-to-end process of eWM & QR-based transactional automation on mobility devices at manufacturing sites of Reliance • Designing & implementation of OTP driven paperless Inspection system recorded via TAB linked with SAP • Designing & implementation Scrap management dashboard integrated with SAP • Installation & commissioning of fire & Gas upgradation project at Nagothane Manufacturing Division Leadership • Headed inbound function of Materials & trained the site team on the same • Headed cross departments namely SAP, FICO, Procurement, Site maintenance & operations team for implementation of process improvement & digitization projects Certifications • EGMPx certification from Indian Institute of Management, Bangalore [October 2019-July 2020]. Selected in young 40 talent recognized as 'FLYERS' by Reliance. • Data-Driven Supply Chain Transformation by NITIE and MIT Reward and Recognition • Recognized as excellent performance for consecutive 3 years Experience: 96 Months Career Highlights Dipti Gawand Management Professional with 8+ work experience in Materials management, Project Management, Operations & Maintenance, Perform ance Improvement, SAP MM. Page 13 | Individual Profiles Reliance Industries Ltd, Graduate Engineer Trainee, Reliability 2014 2015 2017 2019 2021 2022 +91 7977530659 dipti.2207013@nitie.ac.in Dipti.Gawand Reliance Industries Ltd, Maintenance Engineer Manager, CoE Materials Management Senior Manager, CoE Materials Management Education BE Instrumentation Mumbai University (2010-14) Reliance Industries Ltd, Reliance Industries Ltd,

- 14. Sales & Marketing • Led the sales and marketing department comprising 15 executives. • Increased the sales revenue by 115 % in 4 years by adding 32 new clients in the portfolio from the pellet, power, cement, and aggregates sectors. • Finalized first export order worth USD 0.3mn with the Australian client. • Developed and introduced the Technical service team and digital marketing team. • New product development for the existing clients in coordination with the development team. • Condu0cting and coordinating the market review meeting every quarter. • Product costing in coordination with CFO and making tactical and strategic decisions accordingly. Project Management • Led the project team for successful installation and commissioning of automated high-pressure molding line along with their auxiliaries and sand plant equipment worth INR 40 Crore within the allotted budget and timeline. • Synchronization of available machinery along with the new equipment for maximum utilization and productivity. • Guided procurement team for new vendor development. • Played a vital role in successfully installing and commissioning fully automatic core shop machines along with auxiliaries worth INR 52 Crore in an automotive foundry. Operational & Process Excellence • Led the Production department having a team of more than 200 manpower. • Increased productivity by more than twice within two years by improving the average yield of casting by 10% and improving power utilization. • Manufacturing Cost reduction by 5% which resulted in an annual saving of INR 3.6 Crores through consumption monitoring, reviewing, and rejection controls. • Established In process quality checklist procedures and implementation of 5S, TPM, KAIZEN, History Card, TQM, and Job Standards. • Achieved less than 0.5 percent rejection in the core shop and reduced sand wastage by 50%. Rewards and Recognitions • Received Employee of the Year award for outstanding performance at Blue Star Malleable Pvt Ltd. • Received Employee of the Month award at Oliver Engineering Pvt Ltd. • Received Merit cum means Scholarship from the MHRD, Govt. of India during B. Tech. Positions of Responsibility • Responsibility for Starting the operation during a countrywide lockdown in view of the pandemic in 2020, liasioning with Govt. bodies, and maintaining the COVID-19 protocol. • Student Placement Coordinator – B. Tech., NIFFT, Ranchi. Experience: 109 Months Career Highlights Dushyant Pratap A resilient and goal driven professional with over 9 years of comprehensive experience in sales & Marketing, Project Management and Operational Excellence. Manager, Operations & Project Blue Star Malleable Pvt Ltd Head, Sales & Marketing Blue Star Malleable Pvt Ltd Oliver Engineering Pvt Ltd Process Engineer +91-9801887823 dushyant.2207014@nitie.ac.in Education B.Tech. - Manufacturing Engineering; National Institute of Foundry & Forge Technology, Ranchi Dushyant.Pratap

- 15. Supply Chain Operations • Executed outbound operation of 5 Lacs Square feet warehouse by leading a team of 600 personnel. • Lead resource planning of outbound Operations for Big Billion days-2021 with 5 times increased demand compared to BAU days and utilization of 100% man-hour without disrupting operations flow • Yearly 2.52Cr Manpower cost reduction by introducing AGV in picking operations • Inventory Control by 100% cycle count adherence and E&O planning through the spare market and internal stock transfer analysis • Line Balancing of BS3 and BS4 models Planning And Procurement • Handling Production-planning, scheduling, and Purchase Order work based on Oracle (ERP) through stock verification, physical inspection, MRP adherence, monitoring minimum & maximum level of critical & fast-moving Items • Approx. 1.3 Cr Inventory reduction for A class items through VMI implementation • Schedule Planning and coordination with 27 suppliers with majorly electrical parts (Sensor, harness, starter, alternator, Compressors) and cooling system parts (Radiator, fan guard) and C & D class parts mainly fasteners pats with 1400 parts level. • Smooth transition of BS4 to BS6 engines with 100% OTD and close co-ordinate with marketing and product team for maintaining zero obsolesce Reward and Recognition • Demonstrating Excellence and Teamwork in Implementation of Vendor Managed Inventory (VMI) at Cummins • Best Performer from Inventory Team in Big Billion Days-2021 • Certified Yellow Belt in Area Mapping Dashboard for FC/RC to reduce bulk by 90% from putting bucket • Certified Green Six Sigma on Dynamic Safety Stock Strategy build-up Certifications • Six Sigma Green Belt • Data-driven supply chain transformation by NITIE and MIT. Experience: 84 Months Career Highlights Mahua Mukherjee Total 7 years of diversified work experience in Supply Chain Planning, Procurement, Warehouse Operations and Inventory Management in the Automobile and E- commerce Industry Warehouse Manager Flipkart Department Manager -Inventory Tata Cummins Pvt. Ltd. Cummins India Pvt. Ltd. SCM Planning and Procurement Assistant Manager +91 7632997167 mahua.2207015@nitie.ac.in Mahua.Mukherjee Tata Cummins Pvt. Ltd. Centralized Planning and Procurement Manager EDUCATION:- B.Tech- Electrical Engineering - Academy of Technology

- 16. Strategic Planning • Built and delivered productivity plans by demand forecasts to meet customers’ annual demand of 13 Million Tons • Expertise in conceptualizing and implementing process modifications to enhance operational efficiency, devising order management for more than 900 customers, and In-charge of Internal Logistics and Rake Optimization for 275 customers of the North Indian region. • Engaged with stakeholders for Demand Shaping through a robust S&OP process while ensuring timely order servicing and acting on the variabilities ● Worked on “Increasing Coil Weight in Hot Strip Mills”, and awarded “Best Kaizen Project” for the same Leadership & People Management • Led various Strategic Projects related to Digitalization, People Management, and COVID-related Special Projects since June 2020, reporting to Executive Vice President - Human Resources. • As “Learning & Development Champion – Vijayanagar Works”, worked on holistic digital quotient and learning approach irrespective of gender, age, experience, and designation Process Improvement and Strategy Development • Led the project on “Enhancement of Mill Production”, resulting in a profit of Rs 41 Crores on net production cost. • Project lead on “Regularization of Human Resources: Back to Normal”, a special project post lockdown for COVID-19, for normalizing 13000 employees to avoid further viral transmission • Worked on Statistical Gap Analysis of the departmental KPIs for setting the Business Plan for the current and forthcoming financial year for the expansion of 18 Million Tons per Annum Certifications • Future Fit Leadership Programme from Indian School of Business (2019-2020) • Certified Six Sigma Executive Black Belt (CSSE-BB) from Henry Harvin • Certified ISO Internal Auditor (IMS) from Omnex (ISO 9001:2015, ISO 14001:2015, ISO 45001:2018) • Data-Driven Supply Chain Transformation 2022 from NITIE Mumbai and MIT (USA) • Certificate of Volunteerism in CSR project–SAKHI (An initiative for the Rehabilitation of female sex workers) led by the JSW Foundation Experience: 94 Months Career Highlights Malyaj Kaushal Passionate and Result Oriented Leader with 7.5+ years of experience in Manufacturing with Technical and Business Domain specialization in Production Planning and Control, Inventory Management, Business Strategy and Leadership Education B.E Mechanical Engineering – O P Jindal University (2010-2014) Page 16 | Individual Profiles +91 9886176863 malyaj.2207016@nitie.ac.in Malyaj.Kaushal JSW Steel Ltd. Assistant Manager JSW Steel Ltd. Deputy Manager 2019 2021 JSW Steel Limited. Graduate Engineer Trainee JSW Steel Ltd. Junior Manager

- 17. Operations Management Managed a team of 30 people at Z Mill for maintaining workflow and spearheaded several improvement projects: -Reduction in breakage and shape correction by 52% in 430 grade by changing work rolls profile saving INR1.5cr quarterly. Handled Process Control of two continuous Annealing and Pickling lines, HR & CR cut to length and cut to slit lines: -Initiated direct processing of hold for testing materials on finishing lines based on their annealing, pickling parameters which resulted in reduction of line idle time due to online sampling by 20% Project Management Led five Brownfield capex projects worth INR200cr: Erection and commissioning of two 20HI Monoblock reversing cold rolling mill, two horizonal bright annealing lines and one cut to length finishing line. Executed Cold Rolling Mill Digitalization by working as Single point of contact between CRM and Vegam Solutions. Deviations and Critical Parameters for each work-station mapped and developed into automatic alert generation, batch traceability also increased by 20% Leadership Headed the operations departments of Z Mill & trained the team on Process Operations, Process safety, Engineering & Operational excellence. Managed a team of 70 contractual people responsible for equipment erection and commissioning Rewards & Certifications: Awarded Best GET in Jindal Stainless Limited Six Sigma Green belt By AIGPE Global Digitization Supply chain by NITIE and MIT. IATF Internal Auditor by Qualniche. Organizational behavior by Emergence Learning Solutions Experience: 73 Months Career Highlights Manish Kumar 6+ years of progressive experience in Operations Management, project Management, Efficiency & Performance Improvement, Management Systems, and Digitalization. Jindal Stainless Limited GET +91 8797057994 manish.2207017@nitie.ac.in Jindal Stainless Limited Associate manager-Process Control Jindal Stainless Limited Associate Manager-Operations Jindal Stainless Limited Associate Manager-Projects EDUCATION: B.Tech- Metallurgical and Materials Engineering NIT Jamshedpur Manish.Kumar

- 18. Operation Excellence • Responsible for executing 200+ improvement projects yearly (Six Sigma BB, GB, Kaizens) across various operations functions such as Sales, Project Management, Planning, Supply Chain Management, Production, Quality, and Testing. • Achieved Cost reduction target for factory Operation every year since 2018. Target Range:500-700 KUSD,2-6 % of the cost of goods sold. • Achieved a 10% reduction in machine manufacturing lead time by executing the Six Sigma BB project on the component brazing process. (Cycle time reduction by 40%) Supply Chain Management • Reduced the logistics cost of imported material by 15% by optimizing the transport logistics and Safety stock in the supply chain and store operations. • Introduced the SharePoint-based portal for Supplier Contracts registration, renewal, and price revision. Reduced the lead time of the entire process by 30% and developed a database for smooth access to all records. Business Excellence • Executed projects to optimize the 5S process, Kaizens, GEMBA meetings, and visual management across the plant. • Executed 5S score improvement project by transforming the 5S audit process, empowering the plant workforce, and resulting in a 15% improvement in 5S score. • Improved GEMBA and Tier meeting productivity by 25% by introducing digital transformation in the whole process Awards • Won Individual trailblazer award in the innovation category for executing Process Digitization Project in operations. (2021) • Won Individual trailblazer award in the Collaboration and Trust category for executing more than 100 cost reduction projects across all segments of operations (2020) Certifications • Six sigma black belt from ISI, Bangalore • Data Driven Supply Chain Transformation from NITIE and MIT • IPBA certification in Business Analytics from IIM Indore • ISO 9001:2015 Internal Auditor from TUV Experience: 107 Months Career Highlights Maulik Doshi High impact and result- oriented leader with nine years of experience in Continuous Improvements/Operation Excellence, Data Analytics, Quality Management, Training & Development functions in the manufacturing sector. Professional experience as Operation Excellence manager, managing continuous improvement & technical training for an organization of over 600 personnel. +91 9619954097 maulik.2207018@nitie.ac.in Maulik.Doshi Quality and Operation Excellence Executive ABB India Ltd. Operation Excellence Manager ABB India Ltd. ABB India Ltd. Machine Service Engineer EDUCATION BVM Engineering – Electrical Engineering (2009-2013)

- 19. Experience: 112 Months Career Highlights Nilesh Nikhade Goal Driven consulting and product development professional with 9.4 years of rich experience in Oil & Gas Industry with experience in both Offshore & Onshore projects. Specialization in Product Development, Advanced Solution Development, Project & Resource Management, Planning, Strategy & Leadership, Process Optimization and Operations Improvement +91 9730776690 nilesh.2207019@nitie.ac.in Nilesh.Nikhade Senior Process Engineer Emerson Electric Co. Senior System Engineer Equinox Software & Services Pvt Ltd. Equinox Software & Services Pvt Ltd. Process Engineer EDUCATION Product Development • Collaborated with global team and client to develop and implement Emerson’s Digital Twin. • Contributed to product development team for process and data flow for Digital Twin. • Developed OTS for various Oil & Gas industry. Project & Operation Management • Delivered a two major Oil & Gas Operator Training Simulator (OTS) projects at offshore site worth $1.8M and $1.5M as Project Lead. • Deputed to United Aram Emirates (UAE) Bahrain, Saudi Arabia for project development and delivery. Lead team in India from Bahrain and UAE remotely for development. Completed three major project cycles from Kickoff Meetings to project delivery. • Involved in techno-commercial negotiating with international client thereby ensuring commercials and quality of projects. • Worked on project planning and resource planning. • Development of proposals for Advanced Solutions to Oil & Gas client. • Key Clients: Shell, TOTAL, ADNOC, Saudi Aramco, Sumitomo Chemicals. Strategy & Leadership • Involved in strategy and leadership team to improve product and implementation process. • Developed a process improvement strategy in a project helping reduction in manhours consumption by 20% in entire project cycle. • Improvised proposal development procedure and enhanced the existing cost estimation tool for proposal development. • Explored current market demand and convinced management for adapting the improvements in the current solution offering thereby diversifying the solution offered and increasing the business. Rewards & Recognition • Recognized by International client: ADNOC Offshore – ZADCO for on-time project delivery with highest quality. • Recognized by Directors and SMTs (Senior Management Team) for delivering training to ADNOC Offshore Operations Team. Certifications • Data-Driven Supply Chain Transformation 2022 from NITIE Mumbai and MIT (USA). • Lean Six Sigma Green Belt –Pursuing from Udemy. LIT, Nagpur – Chemical Engineering (2008- 2012)

- 20. Experience: 5 Years Career Highlights Nitish Kumar Chowdhary Passionate and Result Oriented Professional with 5 years of Experience in Project Management, Business Excellence, Operations & Maintenance Planning, Efficiency & Performance Improvement, Management Systems, and SAP Implementation. +91-8116169817 nitish.2207020@nitie.ac.in Nitish.Chowdhary Education B.Tech. – Power Engineering; National Power Training Institute, Durgapur Project Management • Led end to end project management, monitoring and billing of “Raw water and waste treatment plant” to improve the recycling of water of worth rupees 4.8 crores. • Managed to reduce flue gas exit temperature of PF Boiler by 7°C increases the boiler efficiency by 0.8%, saving 48 L annually. • Lead project of Bio-mass firing in boilers in blend with coal reducing coal consumption per MW by 200t/hr, subsequently saving worth rupees 20 crore. Operations Management • Supervised O&M contractor as shift in charge and able to achieve 100% plant availability, 98.5% Plant load factor and APC( Auxiliary power consumption) close to Design rating i.e. 7.57 MW (9*135 MW) • Spearheaded the annual overhauling of worth rupees 1.2 crores of 135 MW unit and its mechanical, electrical auxiliaries, vendors, manpower, EPC contractors of M/s GE and O&M teams. • Led the project of installation of hybrid ESP, which included procurement of raw materials, negotiation with vendor partners to minimise the stack emission (SOx, NOx,CO) up to 25mg/mm^3 from 130mg/mm^3 in accordance with environmental dept. & boiler factory regulations. Process Excellence & Performance Improvement • Drove various Business Excellence initiatives such as 5S, six sigma projects and Kaizen at workplace. • Implemented the alarm modification of seal air fan in DCS which reduced human error and significantly the number of tripping frequency of the fan. • Managed the project of unaccounted losses reduction in boiler by reducing specific steam consumptions from 3.19 tons/MW to 3.14 tons/MW of worth saving cost of rupees 45.7 lacs. Rewards and Recognition • Won Gold in TQM competition held by QCFI Rourkela for “Alarm modification in DCS” in FY2018. • Received “Best Team of the month” for achieving highest PLF and Availability in 2021. • Won Silver award in CCQC for reducing unaccounted loss and saving of 45.8 lacs. Certifications • Certified Lean six sigma Green Belt. • Certified course of “ Data driven supply chain transformation and Management; NITIE Mumbai 2022. • Certified course on “Additive Manufacturing” by NITIE Mumbai. Vedanta Limited; Control Room Unit Inchrage Vedanta Limited; Assistant Manager, Shift In- charge Power Operations Vedanta Limited; Assistant Manager, Process Performance & Efficiency Vedanta Limited; Team Lead Planning & Performance Improvement

- 21. Experience: 73 Months Career Highlights Priyal V. Shinde Passionate Professional with 6 years of experience in Metal industry with specialization in strategic sourcing, supply chain operations and O&M Management. Expertise in Spend analytics, Market Intelligence, supplier relationship management & problem solving. Strategic Sourcing & Supply Chain Operations • Managed Raw Material Commodity of Rs. 200 cr. annual spend as part of Strategic Procurement Function by monitoring end to end activities across supply chain in collaboration with different stakeholders. • Lead project for debottlenecking of raw material supply chain issues across units for robust & efficient operations. • Exposure in procurement of Digital Capex, IT Revenue ,MRO items and Master Data Management. • Spend Data Analytics & Market Intelligence • Worked on spend data analytics for Upstream & Downstream business and identified opportunities for cost saving, standardization & optimization of supplier base. • Led project for consolidation of Chemical category for centralized procurement based on spend analytics inputs & finalized sourcing strategy for chemical category to achieve potential savings of 10%. • Significant contribution in price trend analysis & Market intelligence for strategic sourcing of raw material commodity. • Leadership & O&M Excellence • Spearheaded cross functional team to eliminate chronic quality issues & cost of unreliability (Rs. 70 lacs) through systematic problem solving. • Lead Reliability cantered projects to improve equipment availability by 3% at finishing lines. • Successfully optimised LNP/lubricant oil consumption at finishing lines & achieved annual savings of ~Rs. 35 lacs with reduction in consumption by 40%. • Focused on Risk mitigation though Critical spares management & new vendor development. • Significant contribution in IIOT project implementation & ERP implementation in downstream business. • Rewards & Recognition • Nominated for Aditya Birla Group Awards under Emerging Professional Category. • Certifications • IMS Internal Auditor certification for ISO 9001:2015, ISO 14001:2015 & ISO 45001:2018, issued by TUV. • Data-driven supply chain transformation by NITIE and MIT. • Procurement Pro Program by Hindalco Industries Ltd. Priyal.Shinde Education B.Tech Mechanical Engg. College of Engineering Pune. Hindalco Industries Ltd. (ABG) YPP, Strategic Procurement Function. Hindalco Industries Ltd. (ABG) Maintenance Engineer Raw Material Sourcing, SPF. Hindalco Industries Ltd. (ABG) Hindalco Industries Ltd. (ABG) Reliability & Maintenance Manager +91 7387638444 Priyal.2207022@nitie.ac.in Priyal.Shinde

- 22. Verdana, White, 10 Supply Chain & Commercials Strategy • Logistics Sourcing & Strategy development & Logistics Blueprint Designs for 2 greenfield & 1 brownfield projects • Vendor evaluation, techno-commercial negotiations and vendor development for 3PL & On-call /Courier Services for 400+ SCP’s with annual buying of 180Cr. • Well versed with Project Management, Zero Base Budgeting, and Logical Cost Preparation, Quotation Analysis, Cost Comparisons & negotiations. • Warehouse layouting design using digital tools like CATIA, Creo according to inventory norms & calculating the Infrastructure , No. of Docks required. Logistics Excellence & Cost Optimization • Reusable, Returnable & Sustainable packaging design in order to achieve more TFR & Optimize cost ; achieved total cost saving of INR 90 Millions which helps to optimize and improve logistic traffic /Warehousing Space and hence reduces cost for 20 Volumetric parts. • Truck volume/TFR maximization through design innovation, and smart and optimised compliance with CMVR guidelines. • Driving Return Load Integration of inbound & Outbound logistics for long haul transportation of HMCL for 5 casting Suppliers in South India. Digitalization & Innovation Projects • The project involve automation of annual paper-based project to App based Service GRN System • Realtime Inbound Supply chain end to end visility Dashboard for 3PL Suppliers Using Control Tower • Digital repository for packaging Data Certifications • Global Online certification course on Digitization Supply chain by NITIE-Mumbai and MIT USA. • Global Online certification on Robotics in Manufacturing & Supplychain by NITIE-MUMBAI. • AutoCad & Catia Design Certificate • Python Basics Pursuing • Basics of Blockchain in manufacturing from Coursera. Rewards & Recognitions • Star GET Award at HeroMotocorp Ltd Experience: 84 Months Career Highlights PUNEET GOYAL Passionate and Result Oriented Professional with Experience in supply chain strategy, Packaging Optimization, logistics budgeting, warehouse layouting & Cost planning, process re- engineering and technology implementation +91 9599119476 Email: Puneet008goyal@gmail.com Puneet.Goyal Education B.Tech: Mechanical Engineering, Thapar Institute of Engineering and Technology. Patiala Hero MotoCorp Ltd. GET Hero MotoCorp Ltd. Assistant Manager- SupplyChain Hero MotoCorp Ltd. Deputy Manager- Commercials

- 23. Project Management • Erection and commissioning of a greenfield project, namely "Fumer Zinc treatment plant," having a budgeted value at 570+crores. • Successfully commissioned two Brownfield projects 1)Sewage treatment plant (25MLD treatment capacity) budgeted value of 45+crores. 2)Raw Zinc treatment plant (50ktpa ZnO) budgeted value of 40+crores • Involved in the creation of Project schedule document, Quality assurance document, Procurement MIS report, Scope document, Performance guarantee document, and Billing breakup document. • Experienced in software like Primavera P6 and Microsoft Project for creating Project Management reports & SAP for processing bills and material inventory. • Well-versed in interpreting project drawings to ensure smooth erection and reduced rework. Business Excellence • Creation of Detail Feasibility Report(DFR) and Environment clearance(MoEF) document for an upcoming greenfield project. The project involved setting up a new Smelter and Fertilizer complex with a budget value of 1500+crores. • Conducted water optimization study of process plant and mine area of HZL partnering with M/s Mecon and M/s Ion exchange limited, which provided a scope of saving 12MLD of water. • Vendor management which involved Vendor technical cum commercial negotiation, vendor performance scorecard report, and vendor training. • Performed standard safety audit and process reviews, trained and certified as scaffolding inspector from M/s Suresafety ltd, crane lifting & shifting approver from M/s Cranebrainz, HAZOP(Hazard and Operability study) & MIQA(Mechanical Integrity and Quality Assurance) from M/s Dupont. Certification • Project Management Professional(PMP) certificate from PMI 2021. • Data-Driven Supply Chain Transformation 2022 from NITIE Mumbai and MIT (USA). Rewards • Recognized as a "Technical star for the year 2019-20" in HZL done in association with M/s Korn Ferry. • Recognized among the top 200 young technical leaders(V-Tech) across the Vedanta groups in 2021. Experience: 60 Months Career Highlights Raman R Result Oriented professional offering nearly five years of experience in Project Management, Erection & Commissioning and Business Excellence. Hindustan Zinc ltd, Vedanta(HZL) GET +91 9116151941 raman.2207024@nitie.ac.in Hindustan Zinc ltd, Vedanta Project Engineer Hindustan Zinc ltd, Vedanta Associate Manager-Projects Hindustan Zinc ltd, Vedanta Project lead Education B.E (Mechanical) College of Engineering Guindy, Anna University Chennai. Raman.Ravi

- 24. Erection, Planning, and Commissioning • Headed the team for all plant-based activities for 4 green field projects of natural gas processing units in RJY asset and Tripura asset of plant capacity 1.0 MMSCMD. (worth 750cr) • Proposed a change for better quality service delivery to the client by coordinating with OEM and studying detailed reports. • Executed enhancements to 2 brownfield projects with a CAPEX of 15 cr. • Well-versed with P&ID and PFD diagrams to ensure accurate installation of process equipment and instruments in a natural gas processing unit. • Leadership • Vouched for the importance of safety training to all the on-field employees of Deep Industries Ltd. by DGMS authorized bodies to tackle unforeseen conditions and implement the learnings to day-to-day roles. • Coordinated with the client to organize audits by Govt. recognized bodies like DGMS and OISD to check for any loopholes in the process safety and eradicate the same. • Operations and Maintenance • Headed the operations team which provided an undisturbed flow of processed natural gas to the client as per the norms set in the contract and PNGRB. • Recorded zero downtime in operations for a period of three years from Dec’16 to Dec’19 which resulted in a direct revenue of 4,140,000 USD. Certifications • Mines Vocational Training by ONGC. • Global Digitization Supply Chain by NITIE and MIT. Experience: 86 Months Career Highlights Subhashish Das A goal oriented professional having experience in the oil and gas sector in the erection, planning and commissioning of natural gas processing units, project execution, project management, client co-ordination, operations and maintenance. Site In-charge Deep Industries Ltd. Project Manager Deep Industries Ltd. Deep Industries Ltd. Graduate Engg. Trainee +91 8106388658 subhashish.2207026@nitie.ac.in Subhashish.Das Education • M. Tech (Petroleum) – PDEU, Gandhinagar. • B.E (Chemical) – JNEC, Aurangabad.

- 25. Strategic Planning • Partnered with strategic planning group in developing mid to long-term Production Forecast and strategized the Production planning accordingly. • Successfully maintained optimum plant inventory level through MSIL Oracle MRP Module. Project Management • Led cross-functional team in successful planning and execution of BS6 K Series engine trials. • Spearheaded a cost-saving project by developing new architecture in Oracle MRP system leading to monthly saving of INR 60 Crore in inventory carrying cost. • Successfully executed End of Production of S-Cross with minimum material obsolescence in coordination with multiple stakeholders. Procurement of Parts for Production • Managed a team of 5 members in daily Procurement of more than 20000 parts required for production worth more than INR 30 Crore. Leadership & People Management • Performed Vital role as Divisional Safety In-charge monitoring health status of people and helping in transitioning from WFH to Office ensuring COVID protocols are followed. Rewards & Recognitions • Awarded for significant contribution in office during COVID Lockdown by MSIL,2020 • Awarded by Indian National Suggestion Scheme for writing a short poem on life,2017 Certifications • Global Certification on Supply Chain Digitization by MIT & NITIE. Area of Interest • Listening & Reading spiritual videos and articles. Experience: 72 Months Career Highlights Rishabh Singh Dynamic and goal driven professional with 6 years of experience in Automobile sector with specialization in Production Planning & Control, Strategic planning, Project Management, Inventory Management & Procurements. Assistant Manager Maruti Suzuki Deputy Manager Maruti Suzuki Maruti Suzuki Graduate Engineer Trainee 2016 2017 2018 2019 2020 2021 2022 +91 9654237908 rishabh.2207025@nitie.ac.in Rishabh.Singh Education B.Tech- Chemical Engg. NIT, Allahabad

- 26. Leadership and Project Management • Led multiple projects worth ~ INR 1500 Crores including a Flagship project in Mumbai worth INR 500 Crores • Advised top management on key strategic initiatives to improve project efficiency resulting in reduced production cost and an increase in working capital • Led a team of 15+ executive engineers and 100+ non-executives for planning, execution, and quality assurance of the projects Digital Transformation and Process Excellence • Facilitated digitalisation objective of integrating cross-functional teams on a single platform to generate real-time project data and harmonized interaction for sound decision-making • Implemented Lean project development methodology to optimize project operation resulting in speedy project completion and increased productivity to 12% Stakeholder management and Collaboration • Managed internal and external stakeholders for formulating effective strategies for timely completion and hand over of projects to clients, achieving business growth • Collaborated with cross-functional teams of sales, marketing strategy, and finance to develop holistic client business understanding and strengthen relationships with end-user Achievements/Idea & Innovation • Dean’s List – Jamanalal Bajaj Institute of Management Studies (MBA Finance – PT) • Idea and Innovation award by the organization for introducing alternative raw material Certifications • Lean Six Sigma Green belt from KPMG, India • Supply chain Analytics from IIT Roorkee • Supply chain Management Specialization from Rutgers University Experience: 96 Months Career Highlights Sumit Singh Agile, results-oriented project manager with eight years of cross- functional experience in project management, strategy formulation, process excellence, and stakeholder management. Education MMS – Financial Management Jamnalal Bajaj Institute of Management Studies, Mumbai B.E. Civil Mumbai University Diploma in Civil Engineering - Veermata Jijabai Technological Institute, Mumbai GET Assistant Project Manager Marathon Group Marathon Group Sr. Executive Marathon Group +91 9833773473 sumit.2207027@nitie.ac.in Sumit.Singh Deputy Project Manager Marathon Group 2014 2015 2017 2020 2021 Assistant Project Manager Larsen & Toubro