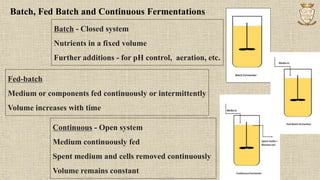

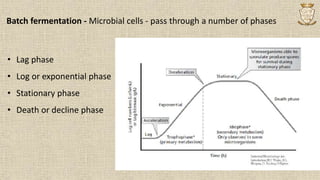

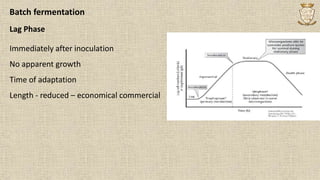

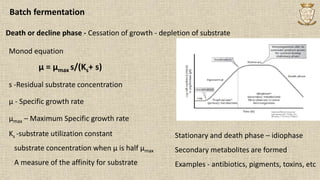

The document discusses various fermentation methods including batch, fed-batch, and continuous fermentation, detailing their operational characteristics, phases of microbial growth, and applications. Each fermentation type has distinct advantages and disadvantages in terms of efficiency, contamination control, and economic viability. The Monod equation is referenced to explain growth rates and substrate utilization in these processes.