This document provides an overview of plastics, including:

- A brief history of plastics development starting in the 1860s.

- Key breakthroughs in plastics chemistry in the 1920s-1930s that led to many new products.

- Increased plastic production during World War 2 to replace scarce natural materials.

- Continued advances in engineering plastics after the war.

- Categories of plastics based on their polymerization process, processability, and chemical nature.

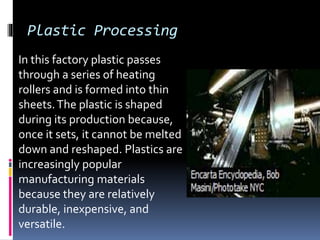

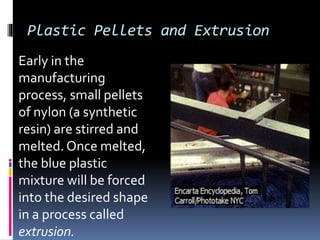

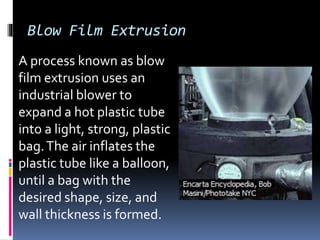

The document also describes plastic manufacturing processes like polymerization, extrusion, and blow film extrusion as well as common additives and issues around plastic waste disposal.