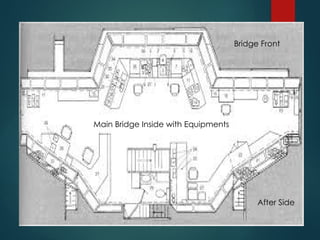

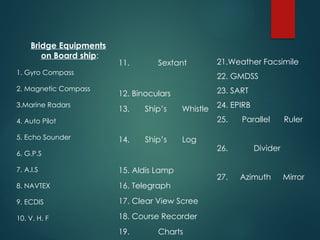

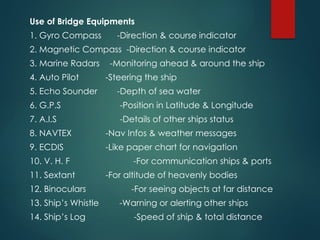

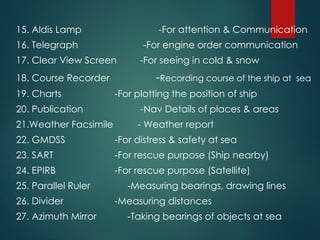

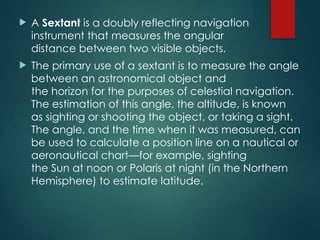

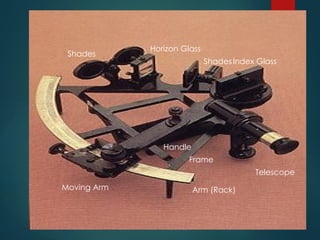

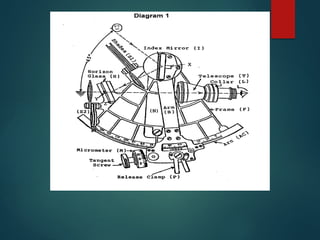

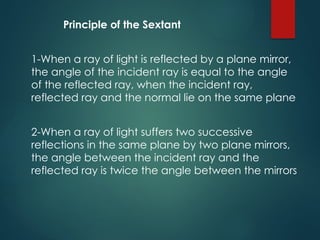

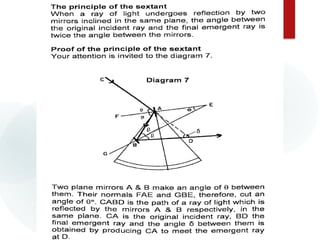

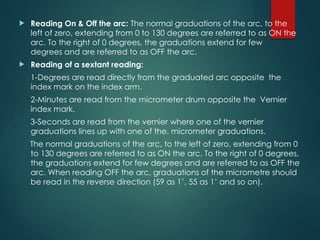

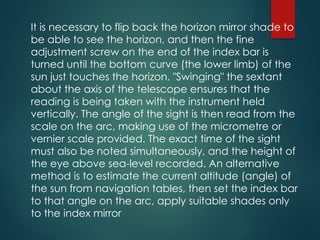

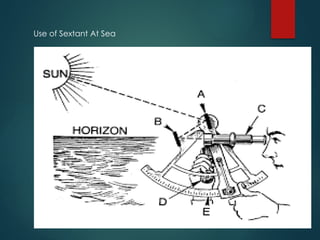

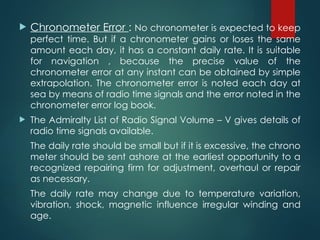

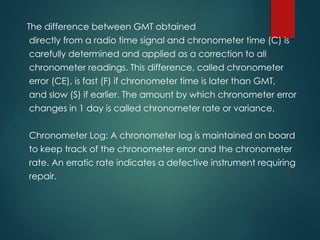

The document outlines the layout and functions of a ship's bridge, including key equipment and systems used for navigation and communication. It details the integrated bridge system (IBS) that connects various navigational tools for centralized monitoring and management, highlighting its advantages and disadvantages. Additionally, it covers the sextant's role in celestial navigation and the importance of proper care and use of this instrument.