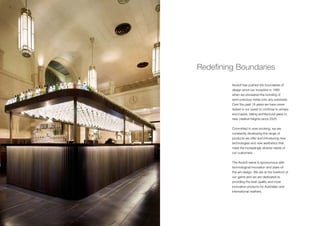

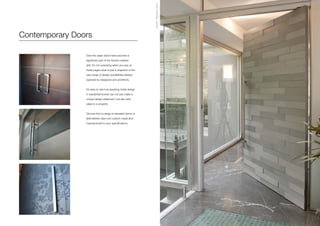

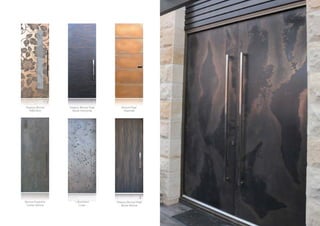

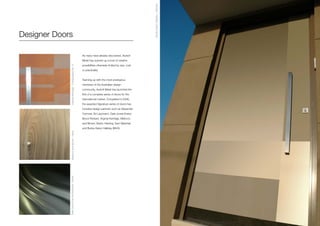

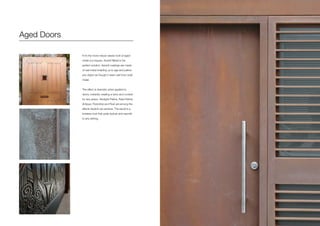

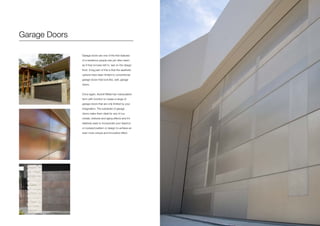

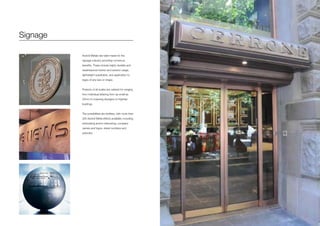

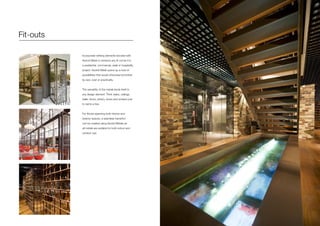

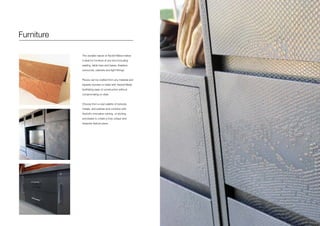

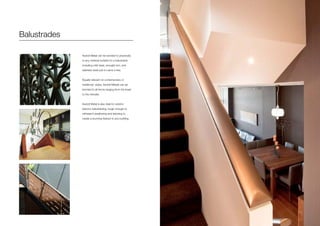

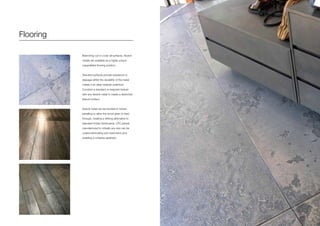

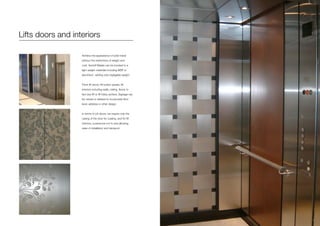

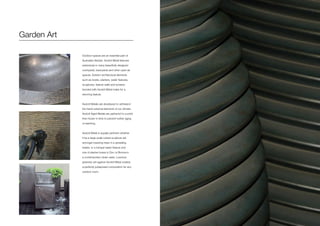

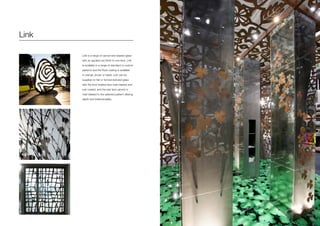

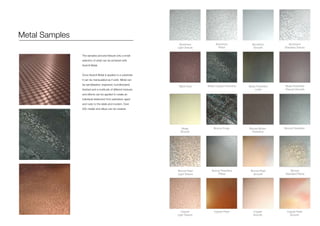

Axolotl Metal is a company that applies semi-precious metals like bronze, brass, and copper onto various substrates through a proprietary bonding technique. They have been innovating metal application designs since 1995. Axolotl Metal works with architects and designers to realize their creative visions, offering a wide range of metal coating applications for doors, gates, facades, walls, floors, furniture, and more. Their metals can be applied to substrates like wood, glass, and steel to achieve unique aesthetic effects.