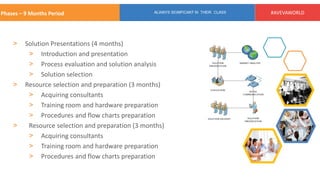

Robert Pesut presented the 'integrated shipbuilding solution' at the Aveva World Summit 2016, detailing its implementation in a restructured shipyard to enhance design speed and production planning. The project aims to reduce errors and improve communication across departments within a nine-month timeline. Post-implementation, significant improvements are expected in design efficiency and material flow.