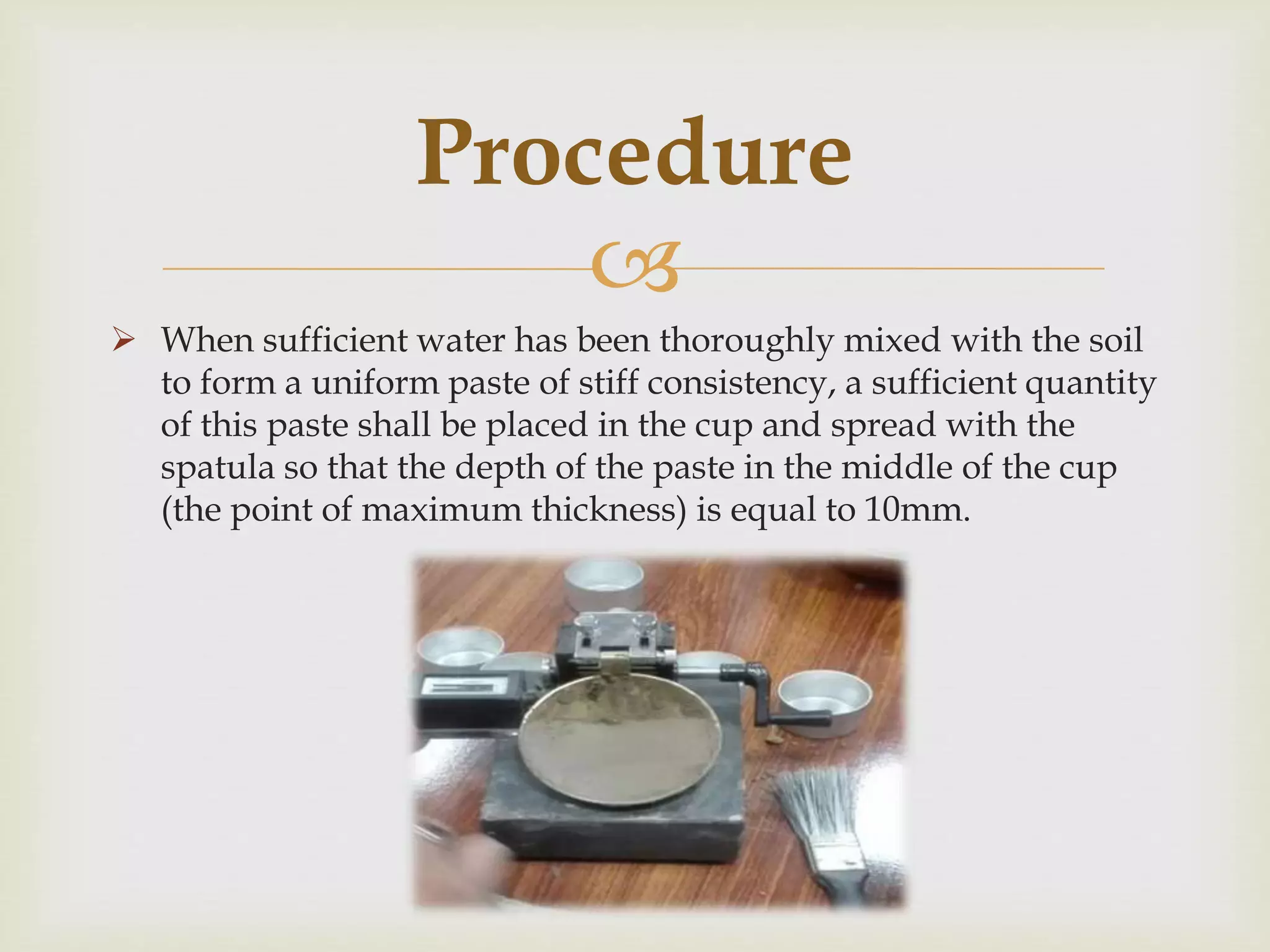

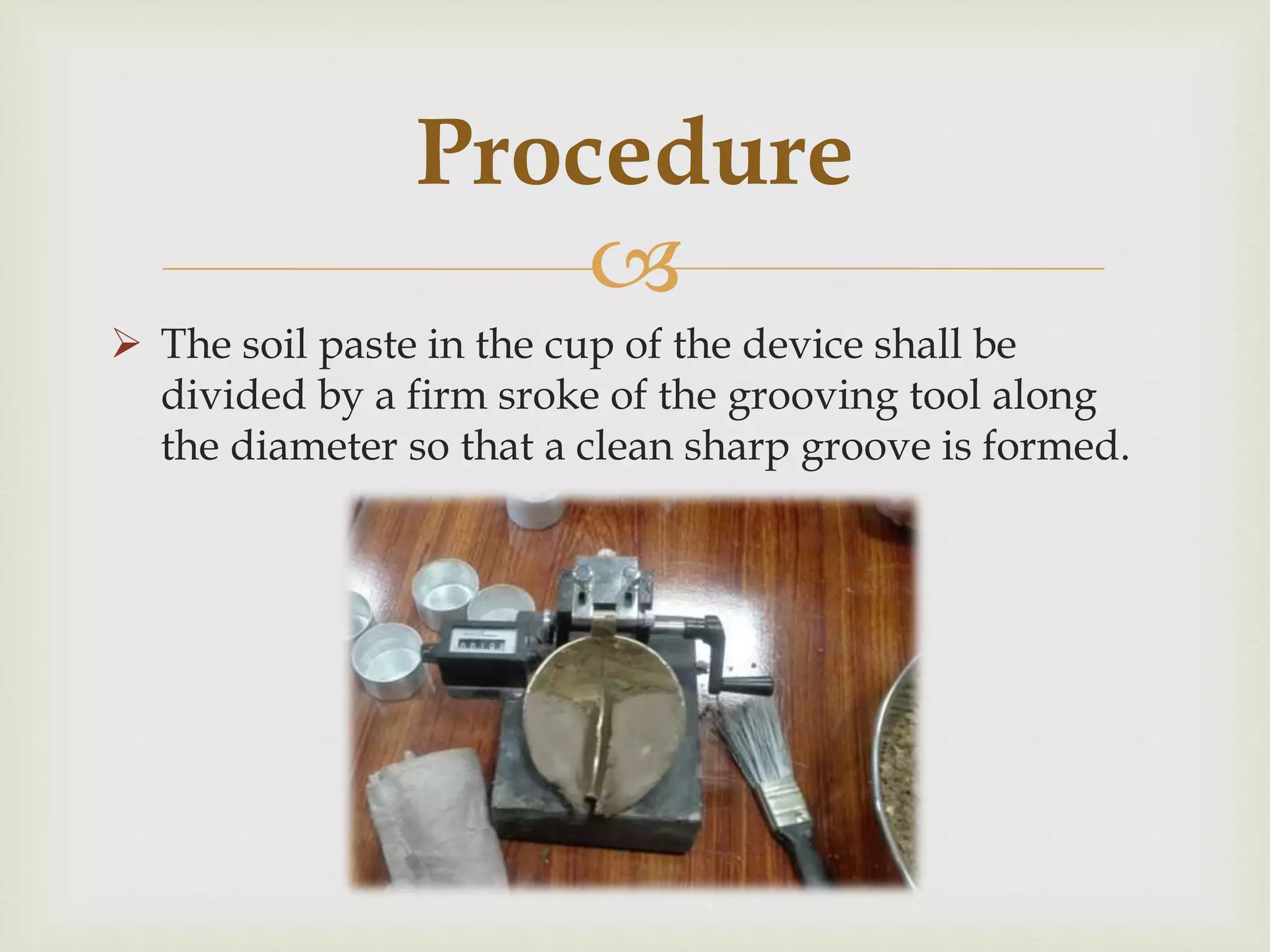

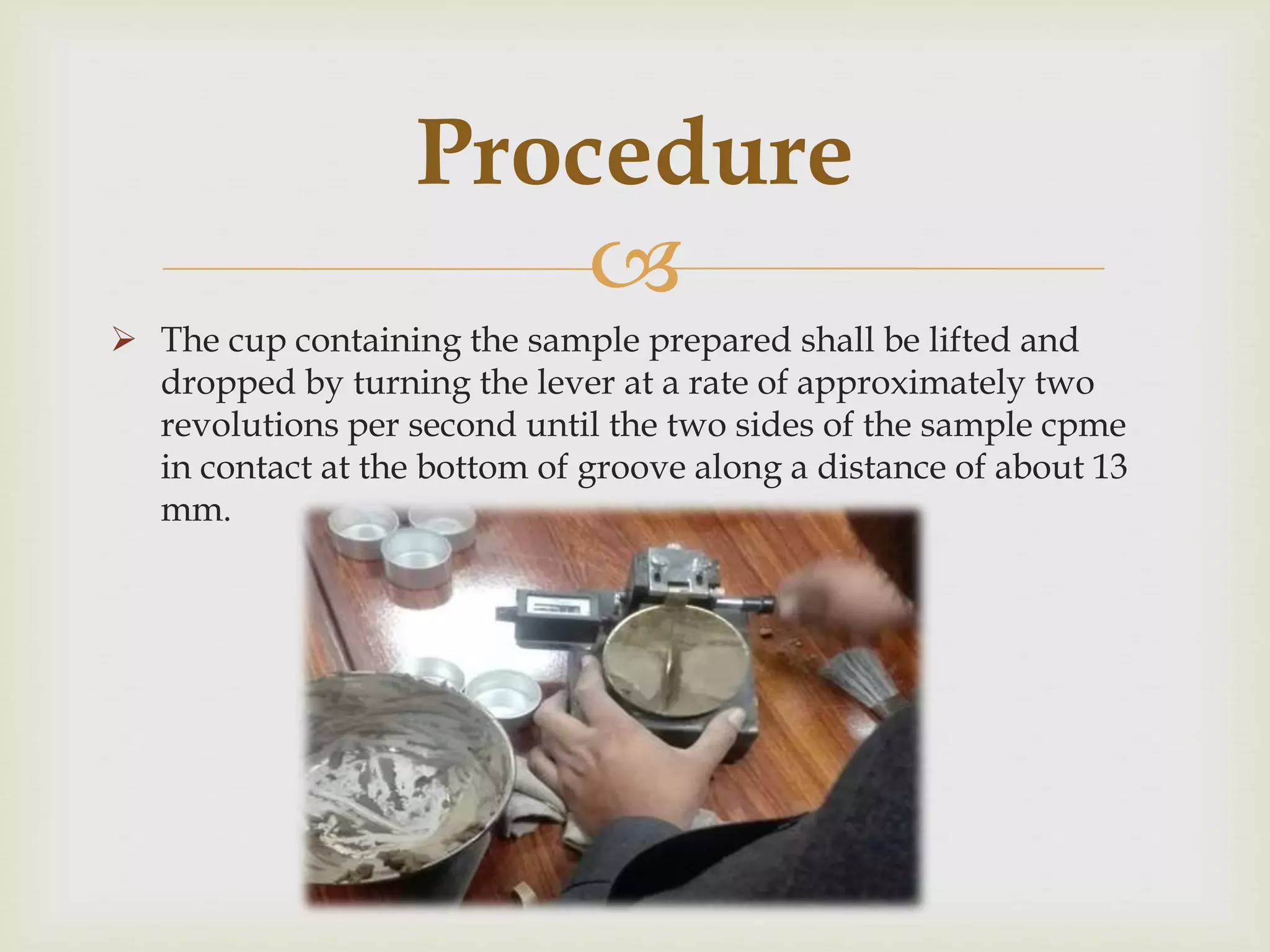

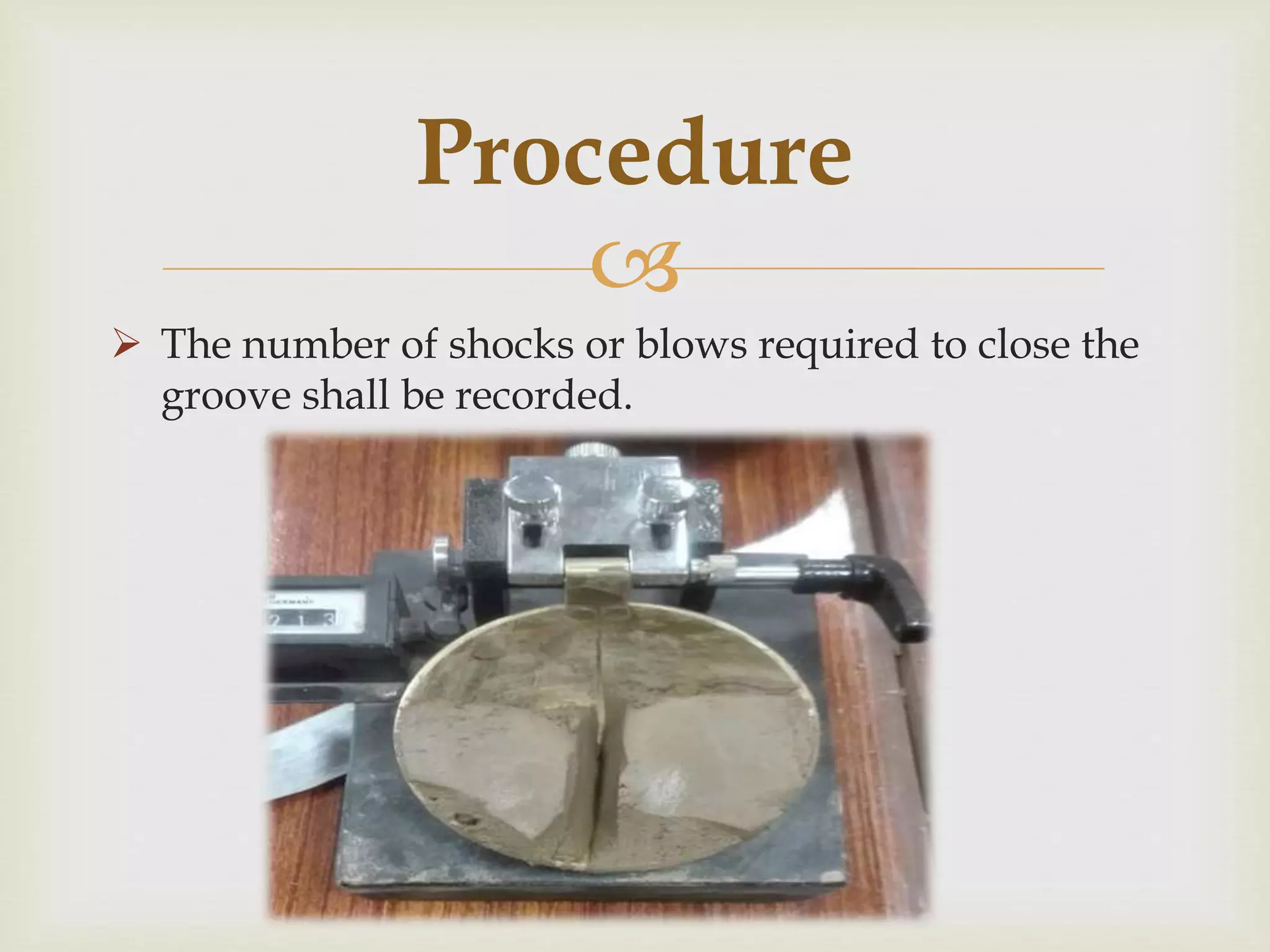

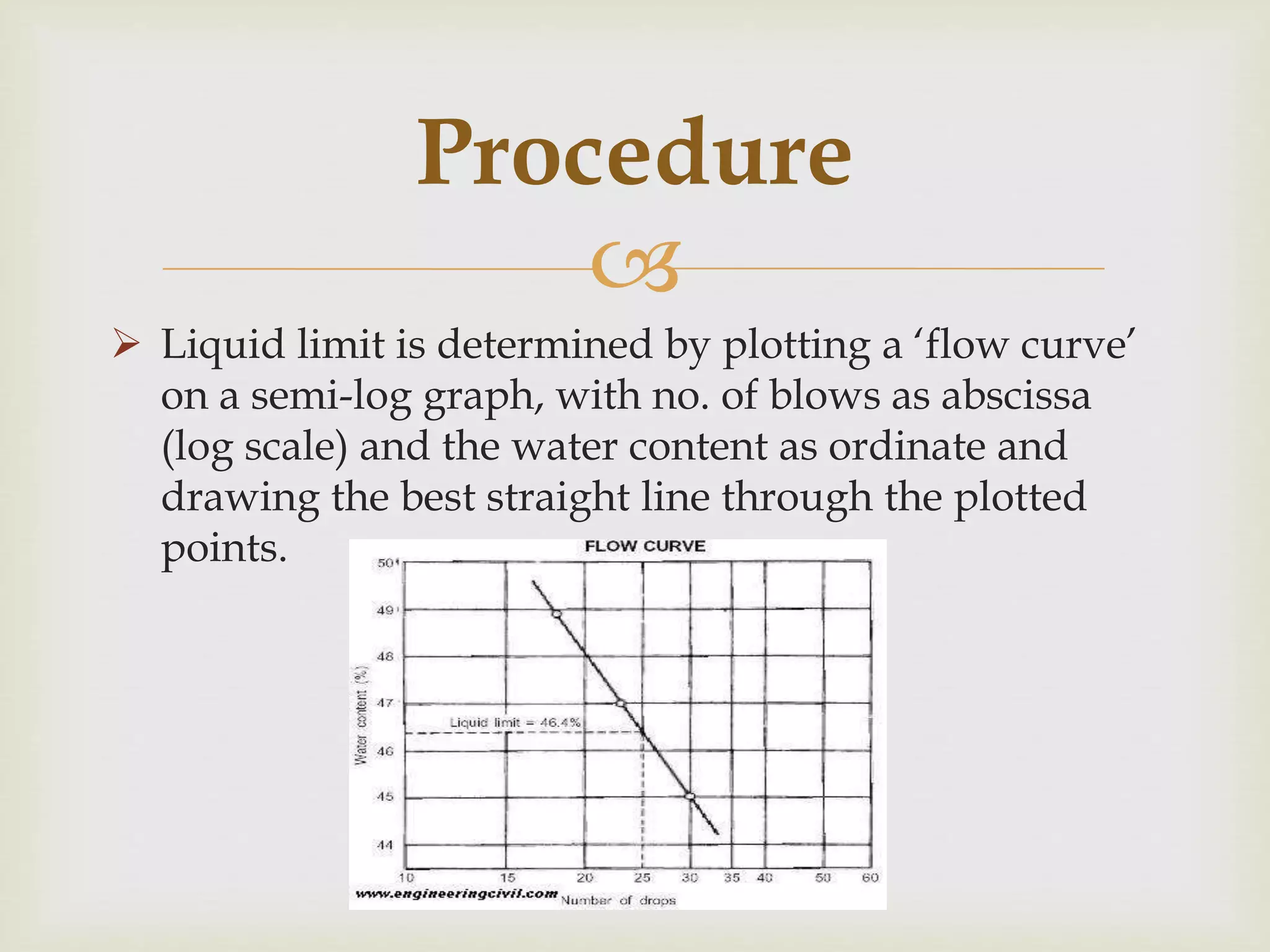

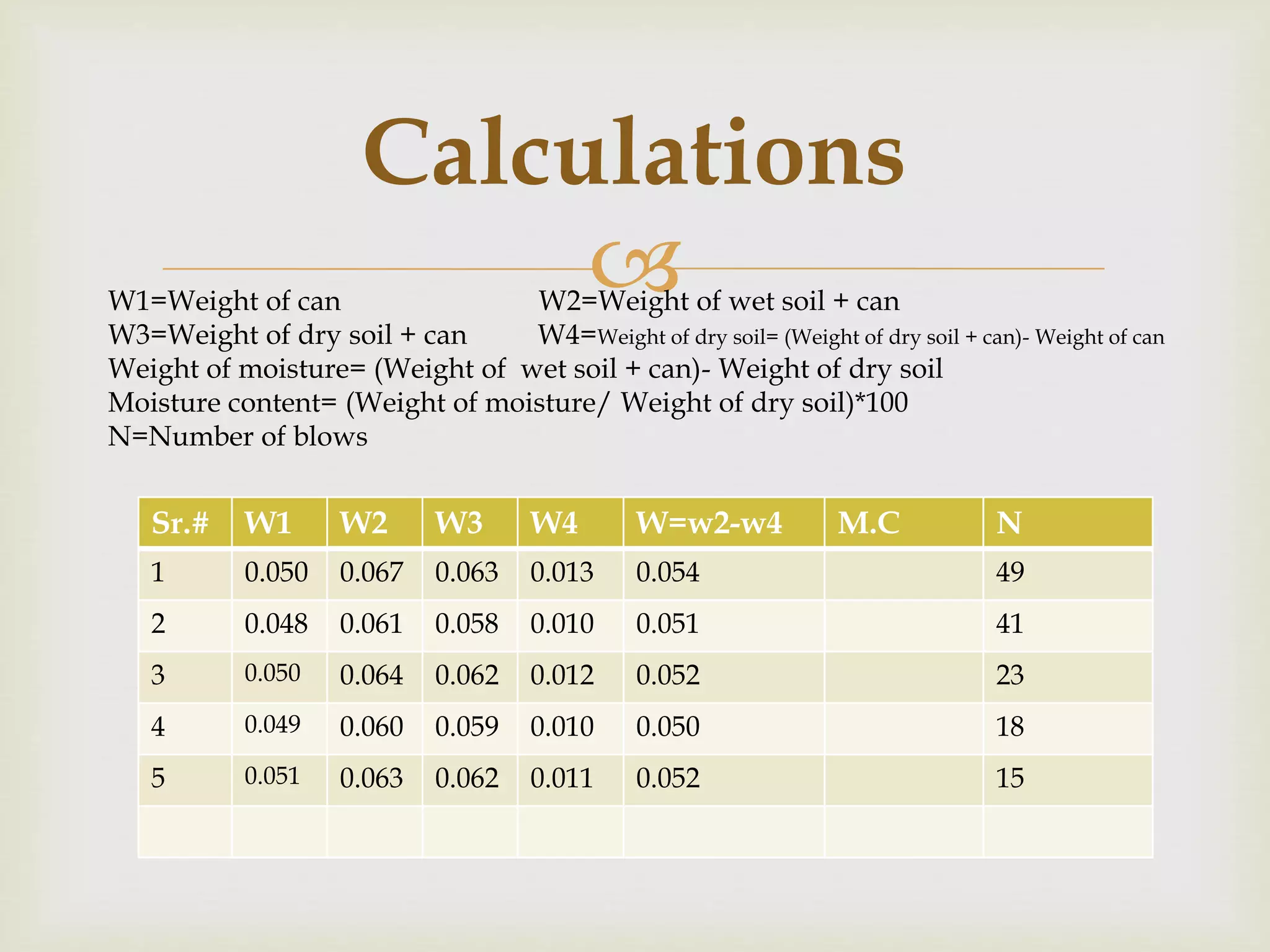

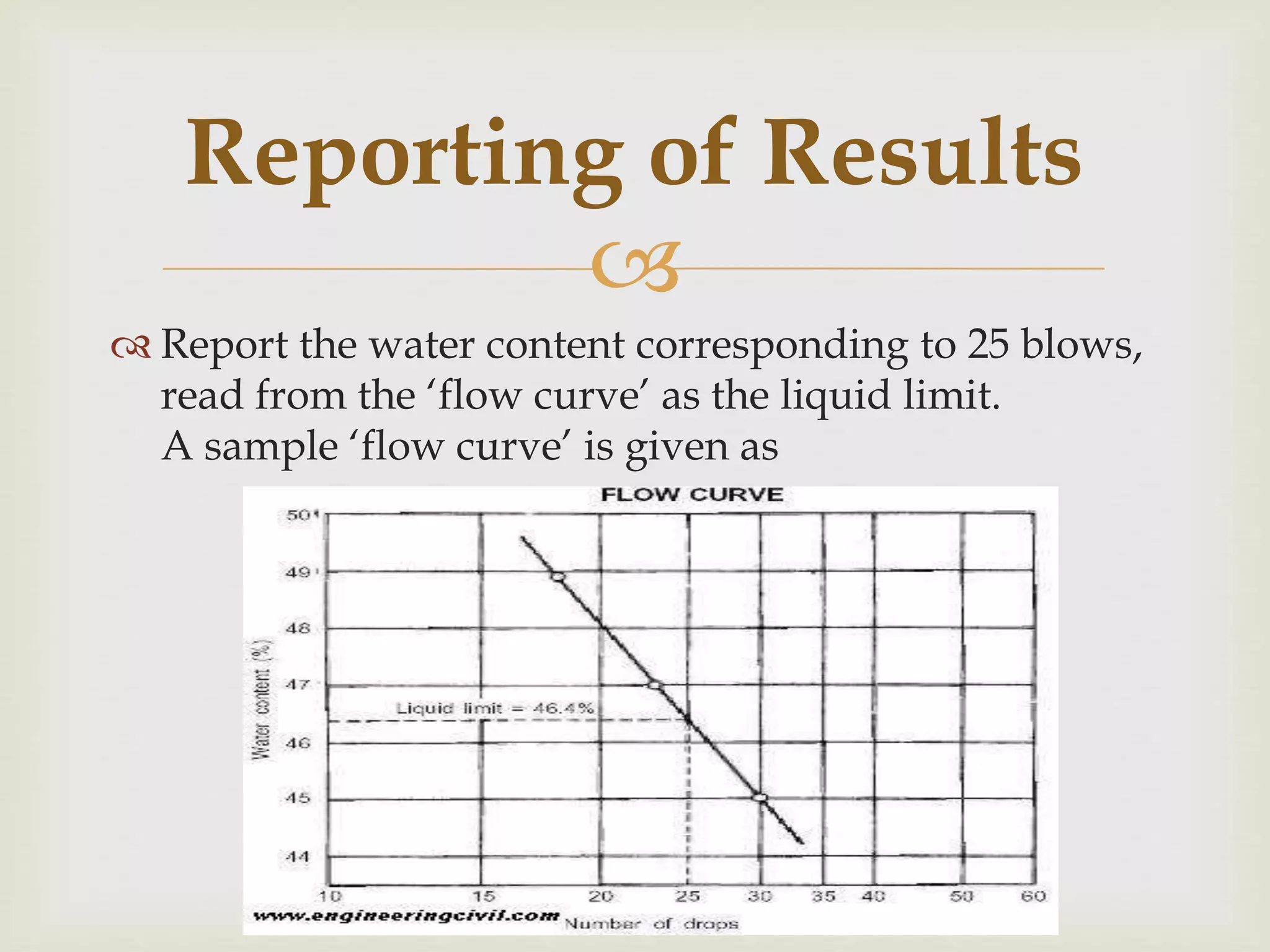

This document describes the procedure to determine the liquid limit of soils according to the Casagrande cup method. It provides background on the concept of the Atterberg limits and defines the liquid limit. The objective is to establish the relationship between moisture content and blows to determine the liquid limit value. The apparatus and step-by-step procedure are outlined. An example calculation is shown. References for additional information are also provided.