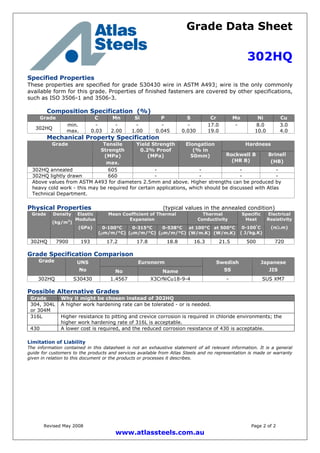

This document provides summaries of various stainless steel grades in the form of grade datasheets. It begins with a foreword describing the purpose and contents. The main body consists of two-page datasheets for numerous grades, including austenitic grades 301, 302HQ, and others; ferritic grades; duplex grades; martensitic grades; and precipitation hardening grades. Each datasheet provides information on the grade's corrosion resistance, heat resistance, heat treatment, welding, applications, specified properties, and typical physical properties.