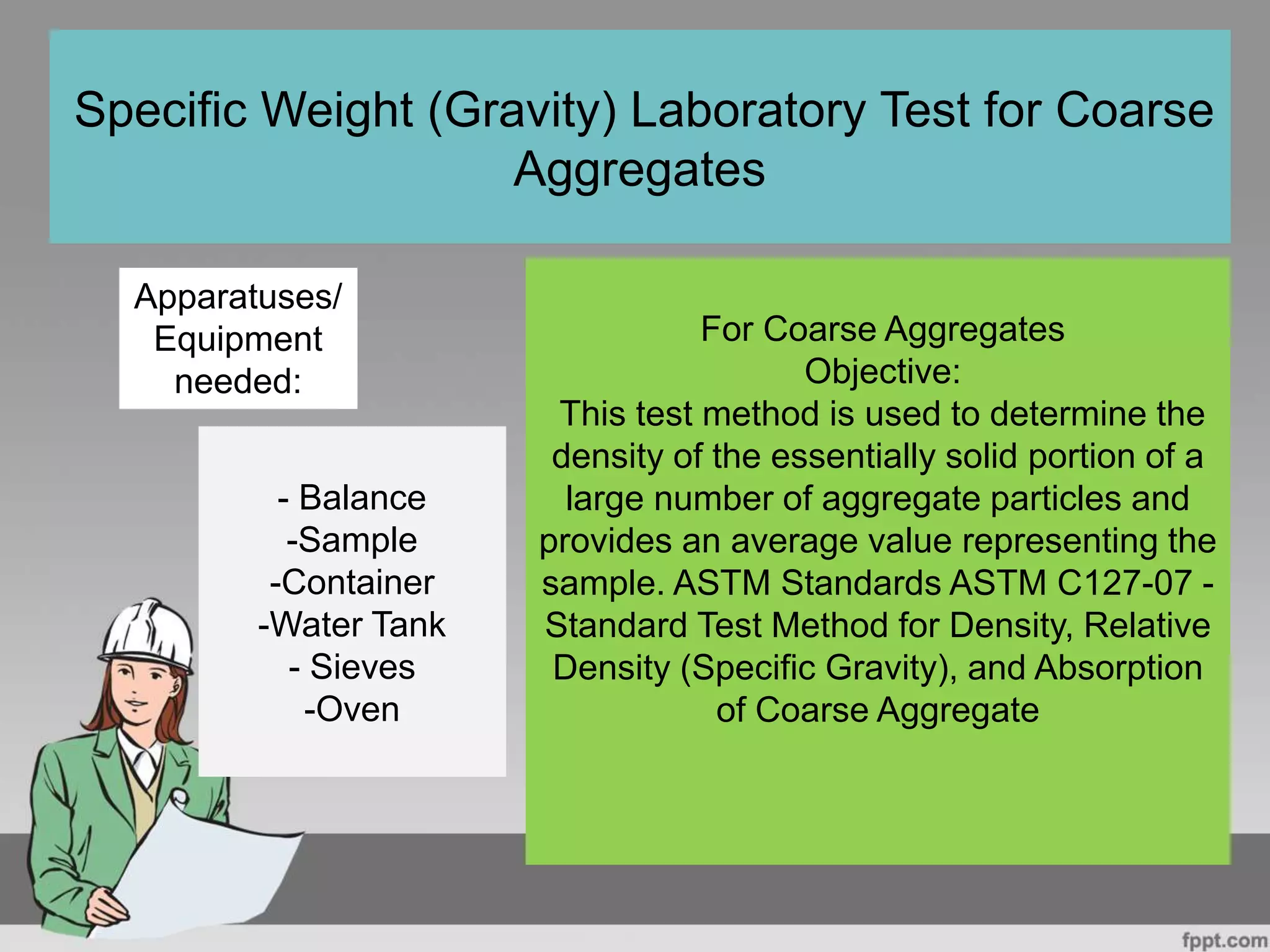

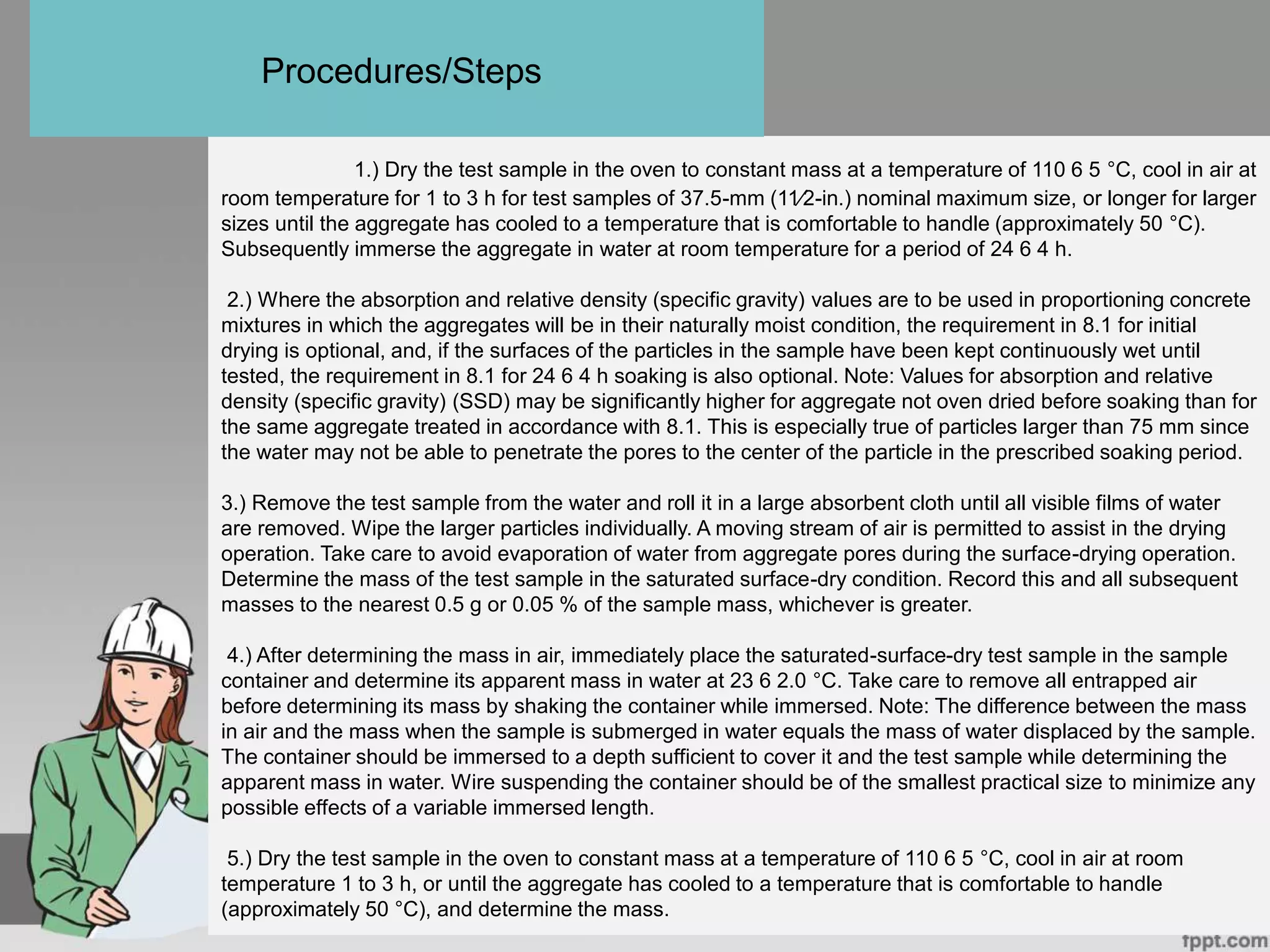

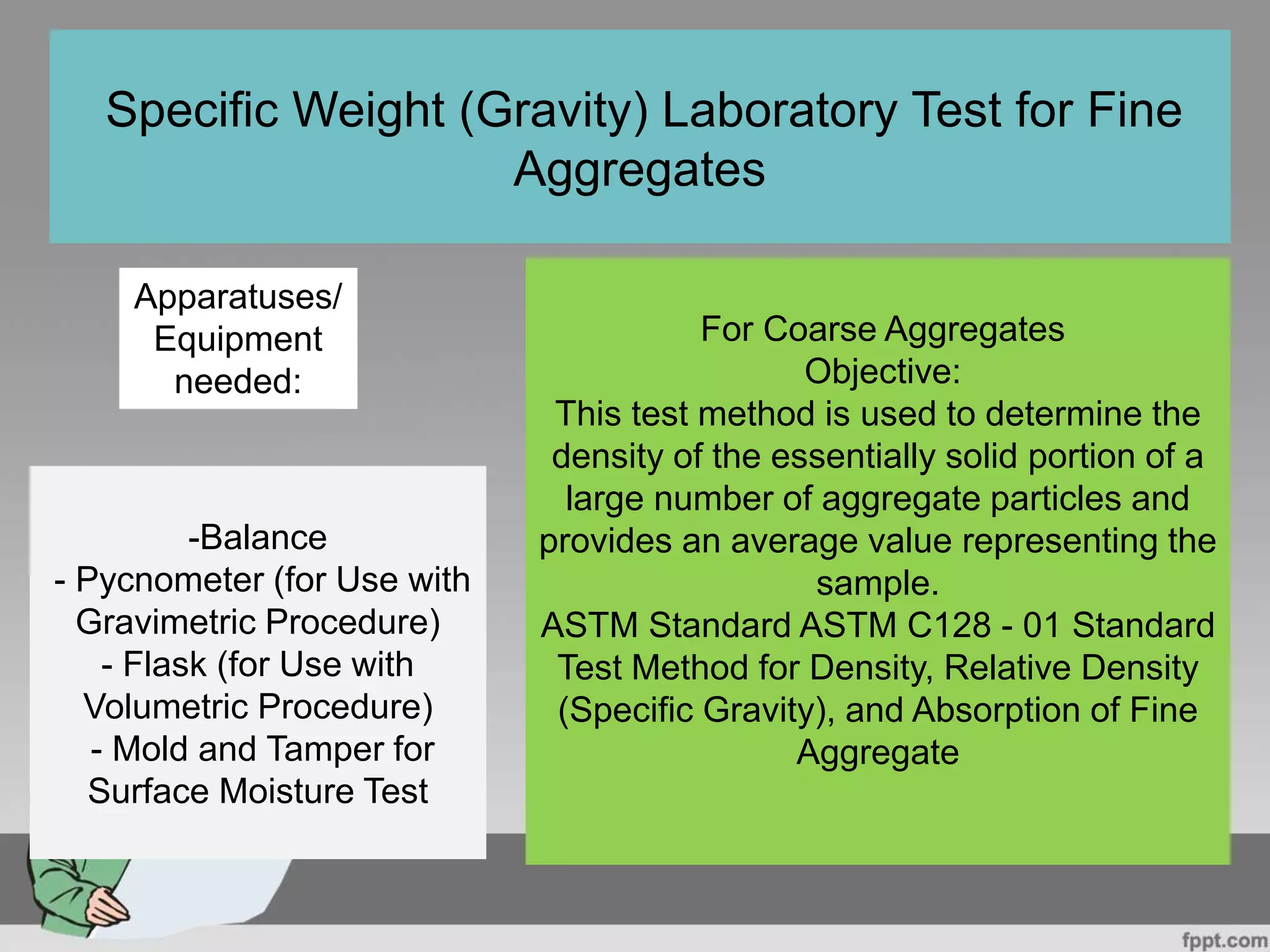

This document provides information on performing laboratory tests for aggregates, including specific gravity and water absorption tests. It lists the necessary ASTM standards, equipment, and step-by-step procedures for conducting the tests on both coarse and fine aggregates. The tests involve steps such as drying samples, weighing them in various conditions to determine densities, soaking samples in water, and calculating absorption percentages. Proper handling and storage of test weights and equipment is also emphasized to ensure accurate results.

![Cylindrical Metal Measure

Apparatus

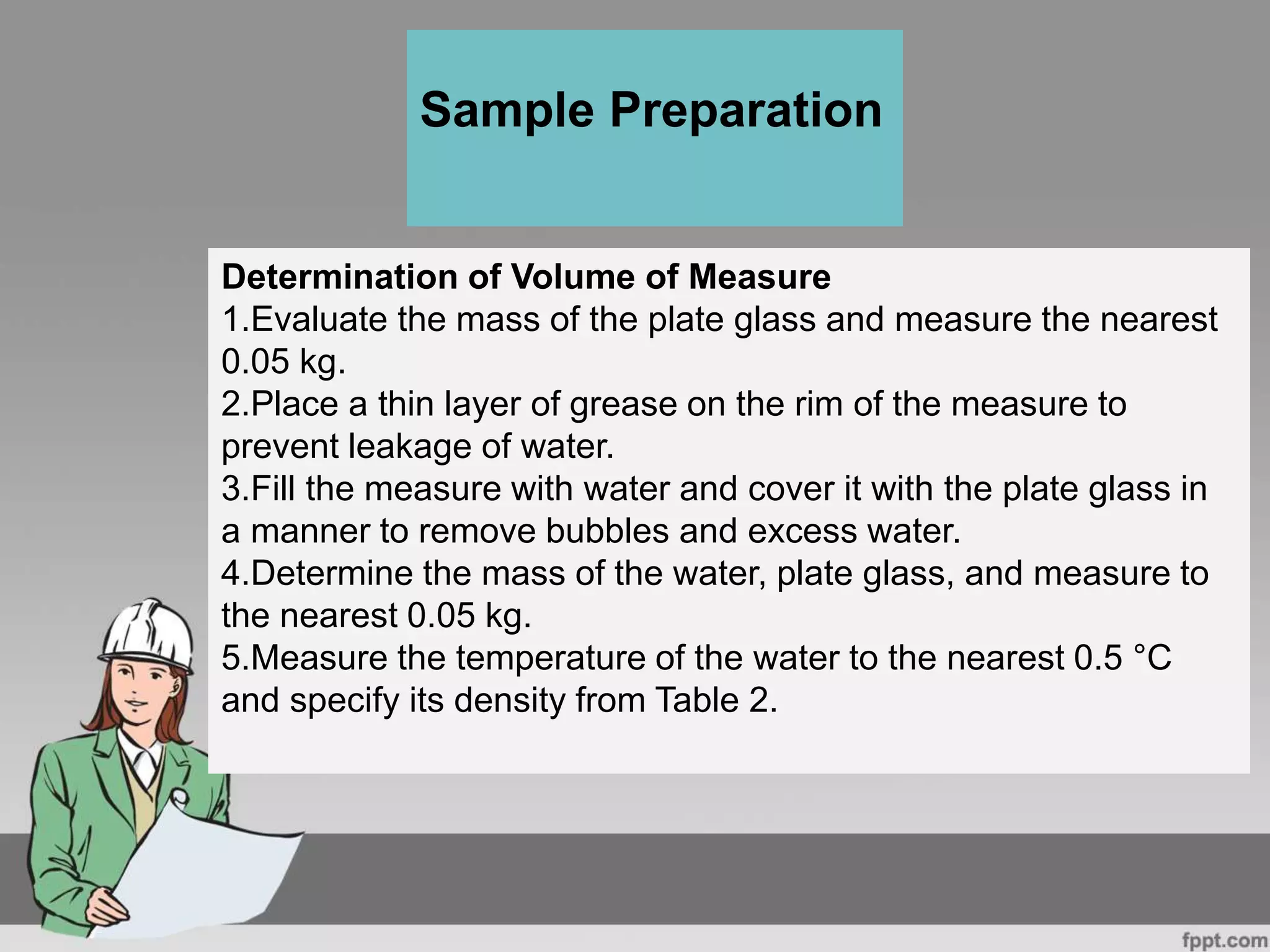

. The capacity of cylindrical

metal measure conforms to

the specifications of Table 1.

Table 1 Capacity of Measures

Nominal

Maximum Size of

Aggregate, mm

Capacity of

Measure, m^3 (L)

12.5 0.0028 (2.8)

25 0.0093 (9.3)

37.5 0.014 (14)

75 0.028 (28)

100 0.070 (70)

125 0.100 [100]

Cylindrical Measures of Different Sizes](https://image.slidesharecdn.com/assignment2cmt-220719042117-e75fe909/75/ASTM-STANDARDS-IN-PERFORMING-LABORATORY-TEST-FOR-AGGREGATES-27-2048.jpg)

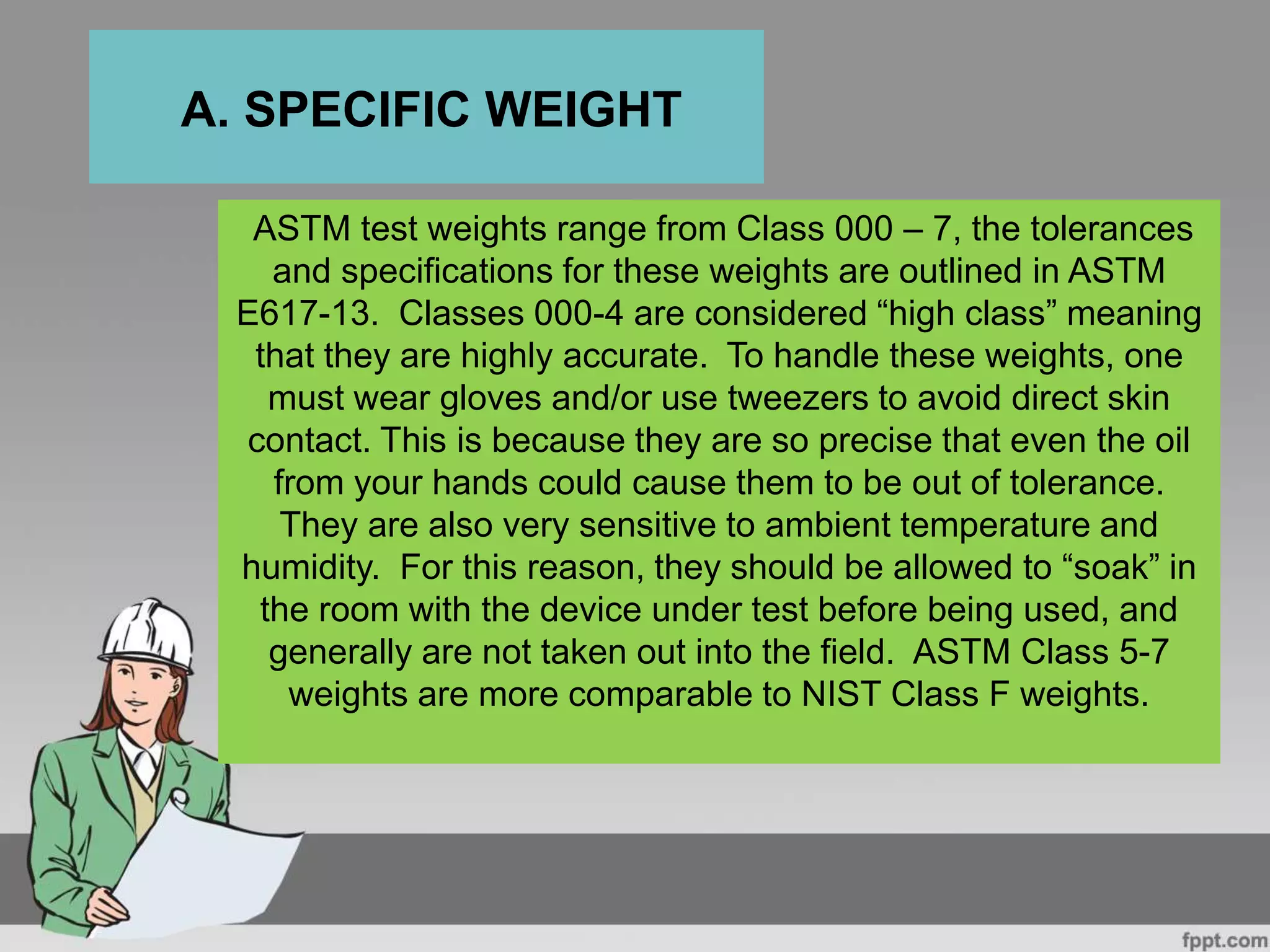

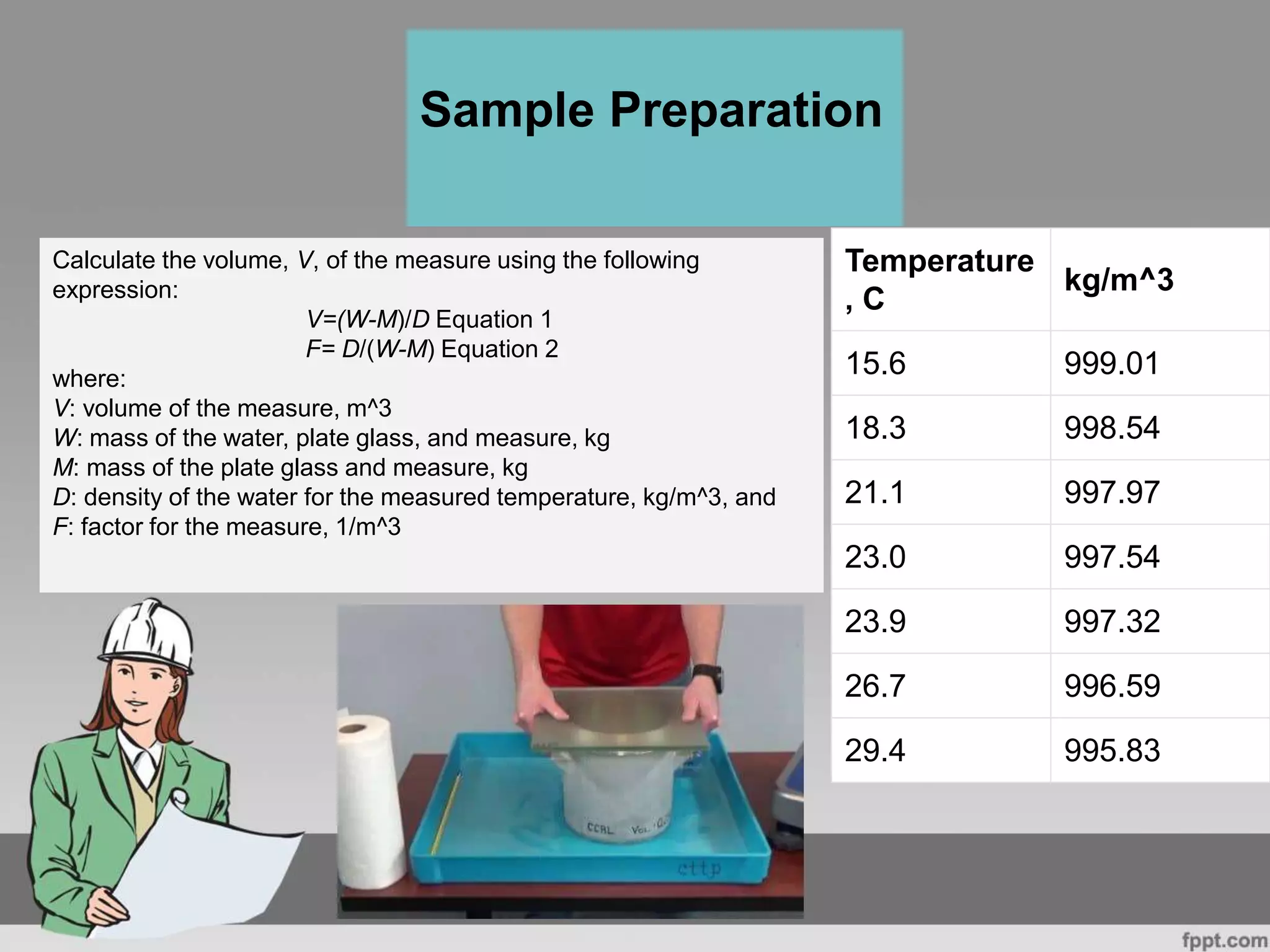

![1. Calculation of Compacted Bulk Density of aggregate

Bulk density (M)= (G-T) / V Equation 3

Or

Bulk density (M)= (G-T) / F Equation 4

where:

M: bulk density of the aggregate, kg/m^3,

G: mass of the aggregate plus the measure, kg,

T: mass of the measure, kg,

V: volume of the measure, m^3,

F: factor for measure, m^3, computed from equation 2.

The bulk density determined by this test method is for aggregate in an

oven-dry condition. If the bulk density in terms of saturated-surface-dry

(SSD) condition is required, it can be computed using the following

formula:

Mssd= M[1+(A/100)] Equation 5

where:

MSSD : bulk density in SSD condition, kg/m^3.

A: % absorption,

Calculations](https://image.slidesharecdn.com/assignment2cmt-220719042117-e75fe909/75/ASTM-STANDARDS-IN-PERFORMING-LABORATORY-TEST-FOR-AGGREGATES-33-2048.jpg)

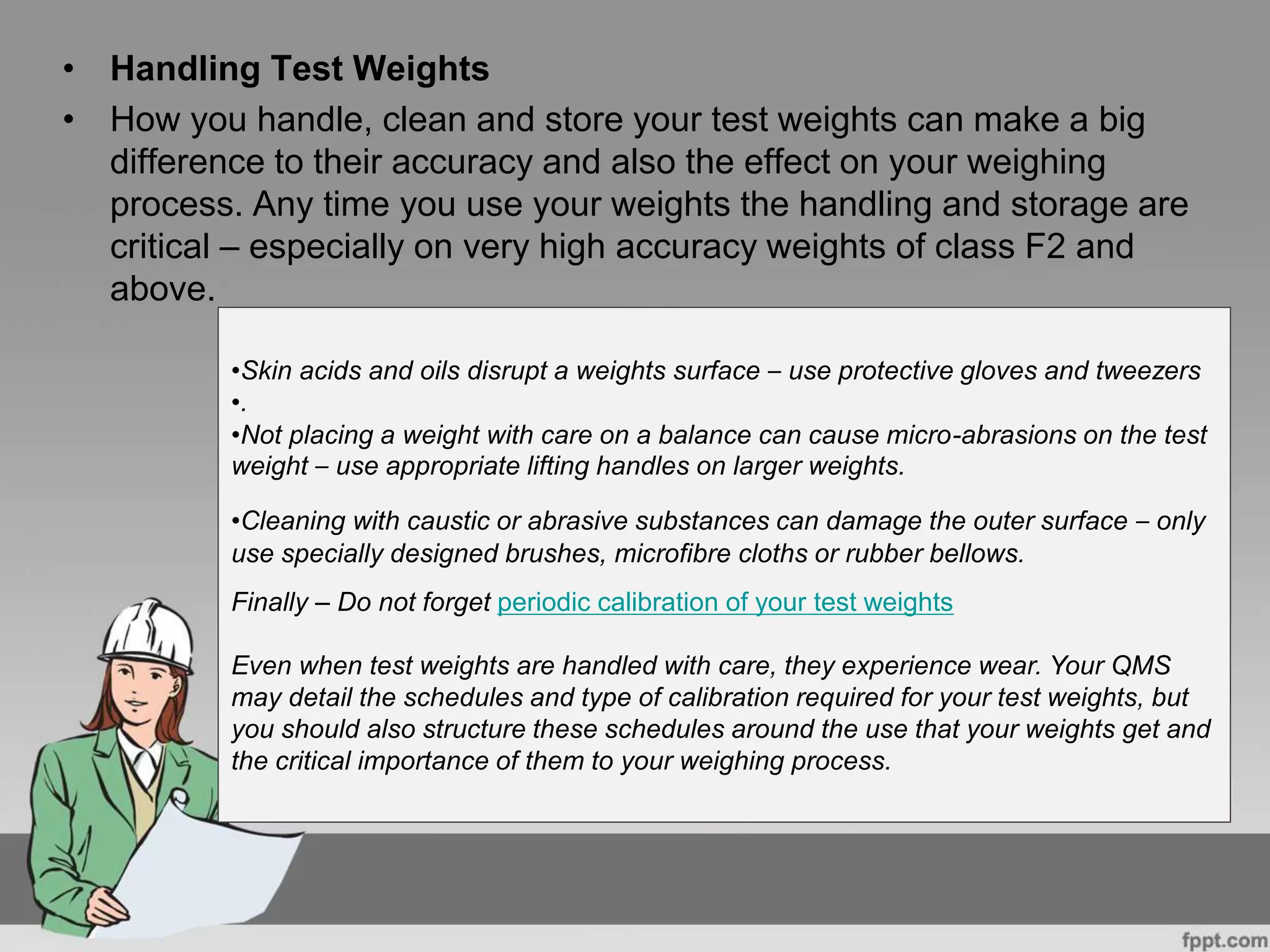

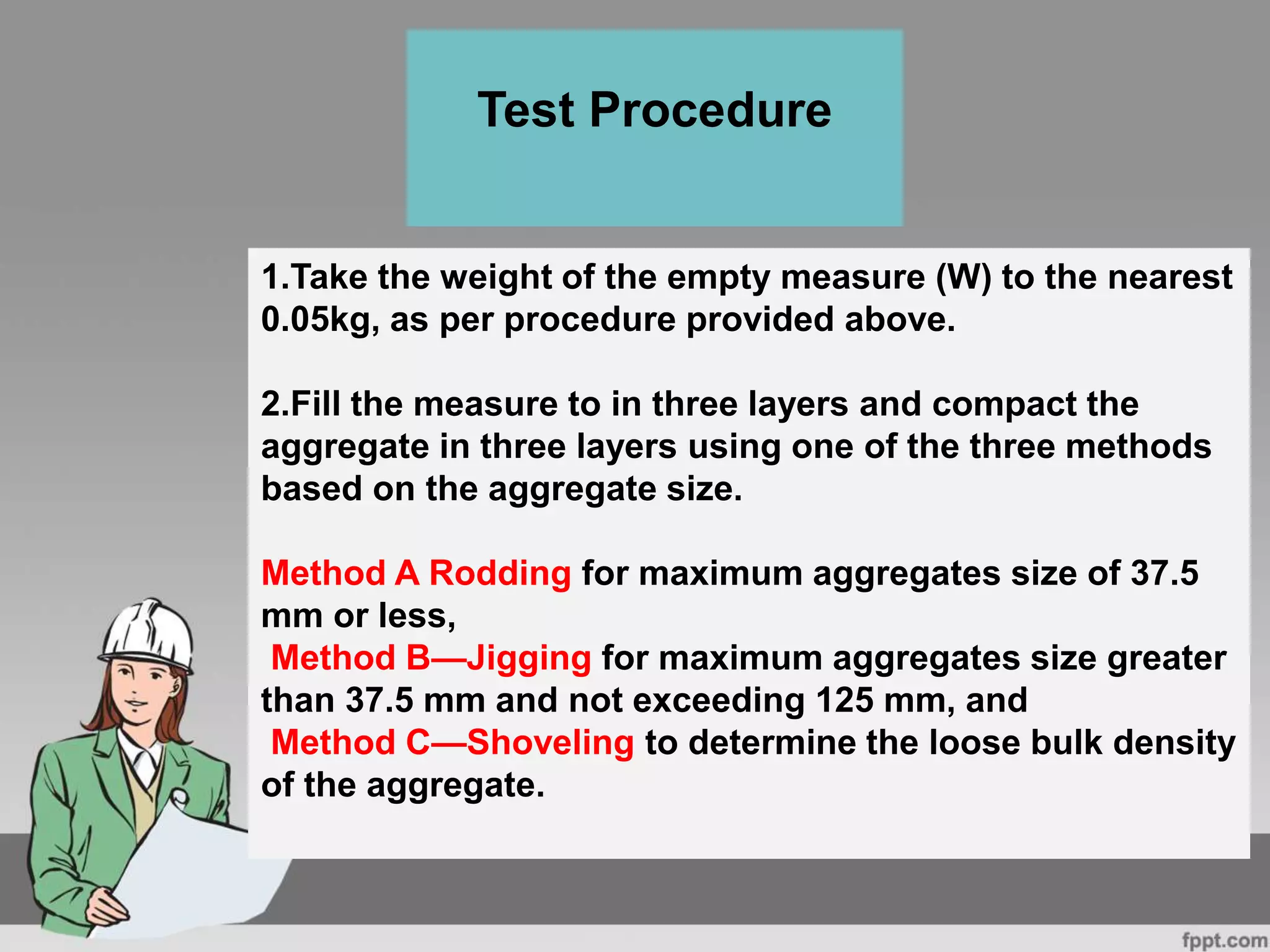

![2. Void Content

Calculate the void content in the aggregate using the bulk

density determined by either the rodding, jigging, or shoveling

procedure, as follows:

%Voids= 100[(SxW)-M]/ (SxW) Equation 6

where:

M: bulk density of the aggregate, kg/m^3,

S: bulk specific gravity

W: density of water, 998 kg/m^3

Calculations](https://image.slidesharecdn.com/assignment2cmt-220719042117-e75fe909/75/ASTM-STANDARDS-IN-PERFORMING-LABORATORY-TEST-FOR-AGGREGATES-34-2048.jpg)