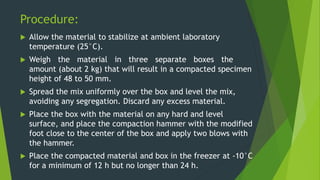

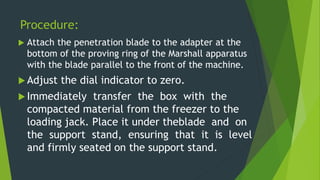

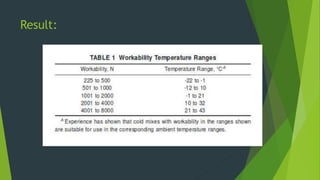

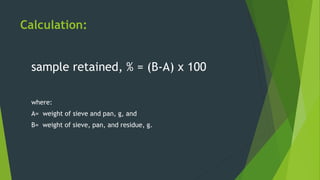

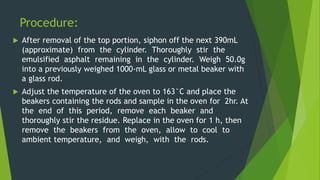

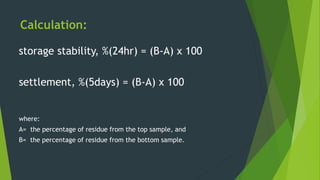

This document describes test methods for determining the properties of asphalt and emulsified asphalt materials. ASTM D6704 describes a test to determine the workability of cold mix asphalt patching material by measuring penetration after compaction and freezing. ASTM D6933 details a test for measuring oversized particles in emulsified asphalt using a sieve. ASTM D6930 provides a method for testing the settlement and storage stability of emulsified asphalt by comparing residue levels after evaporating samples from the top and bottom of a stored cylinder.