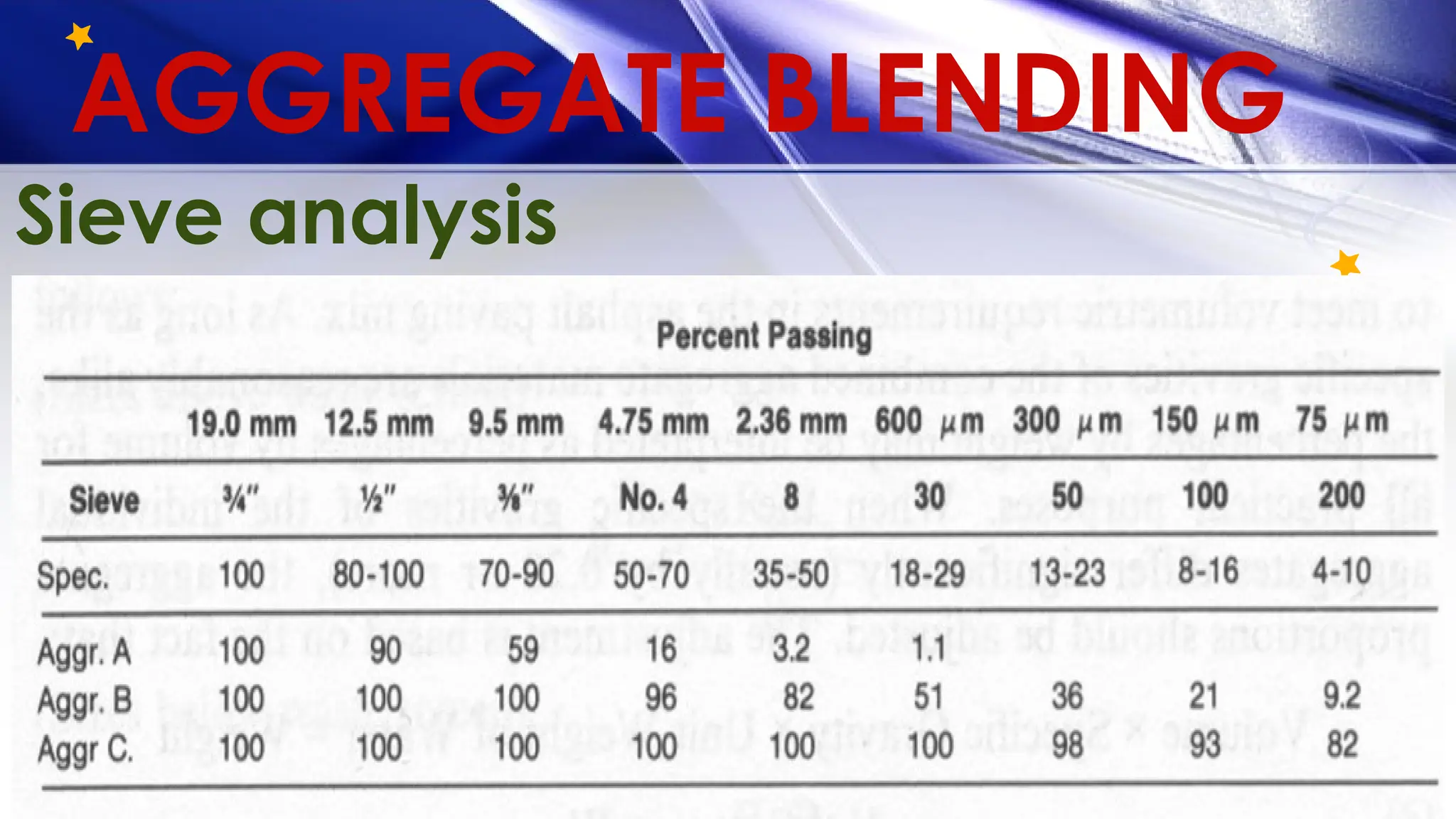

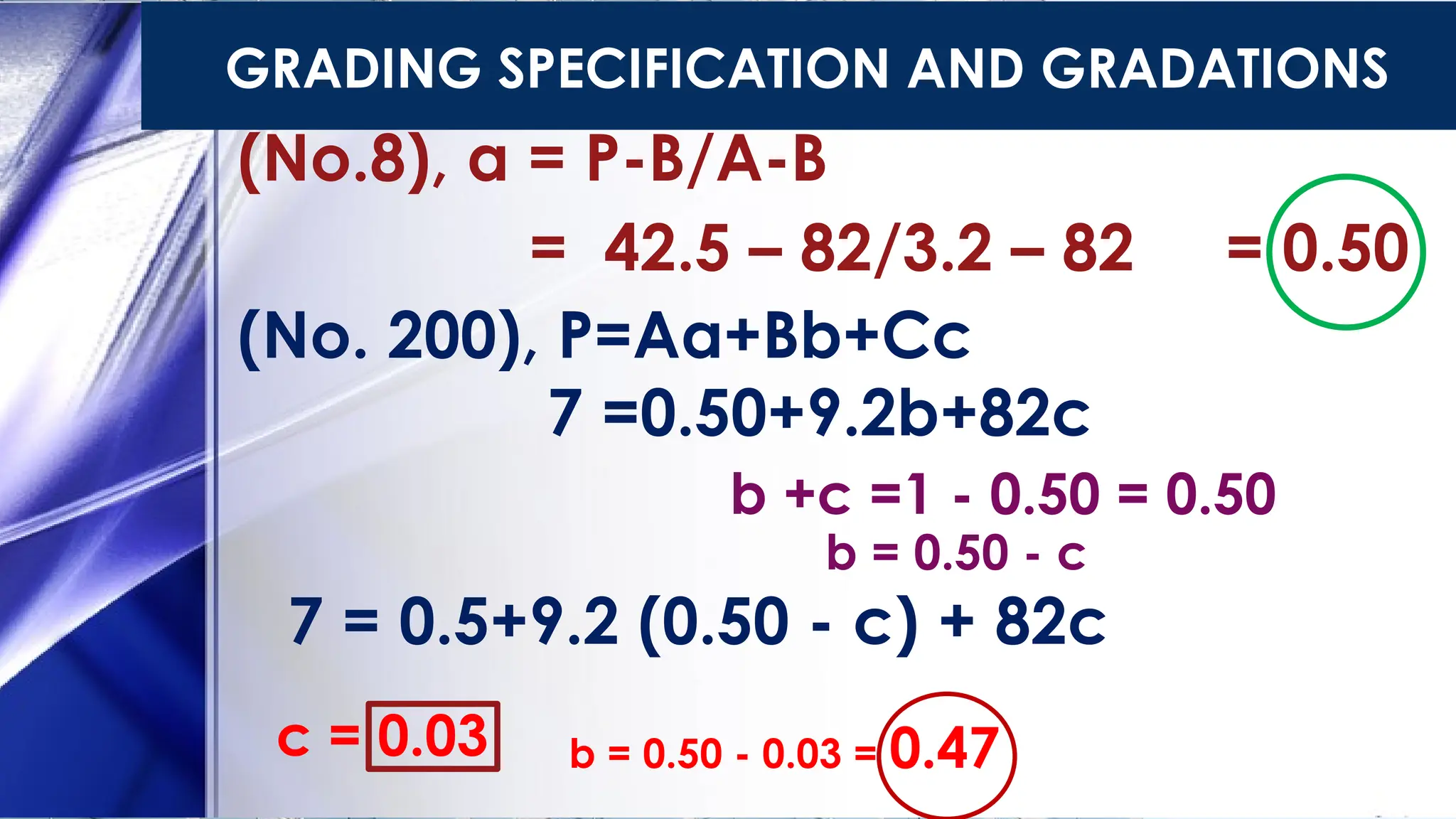

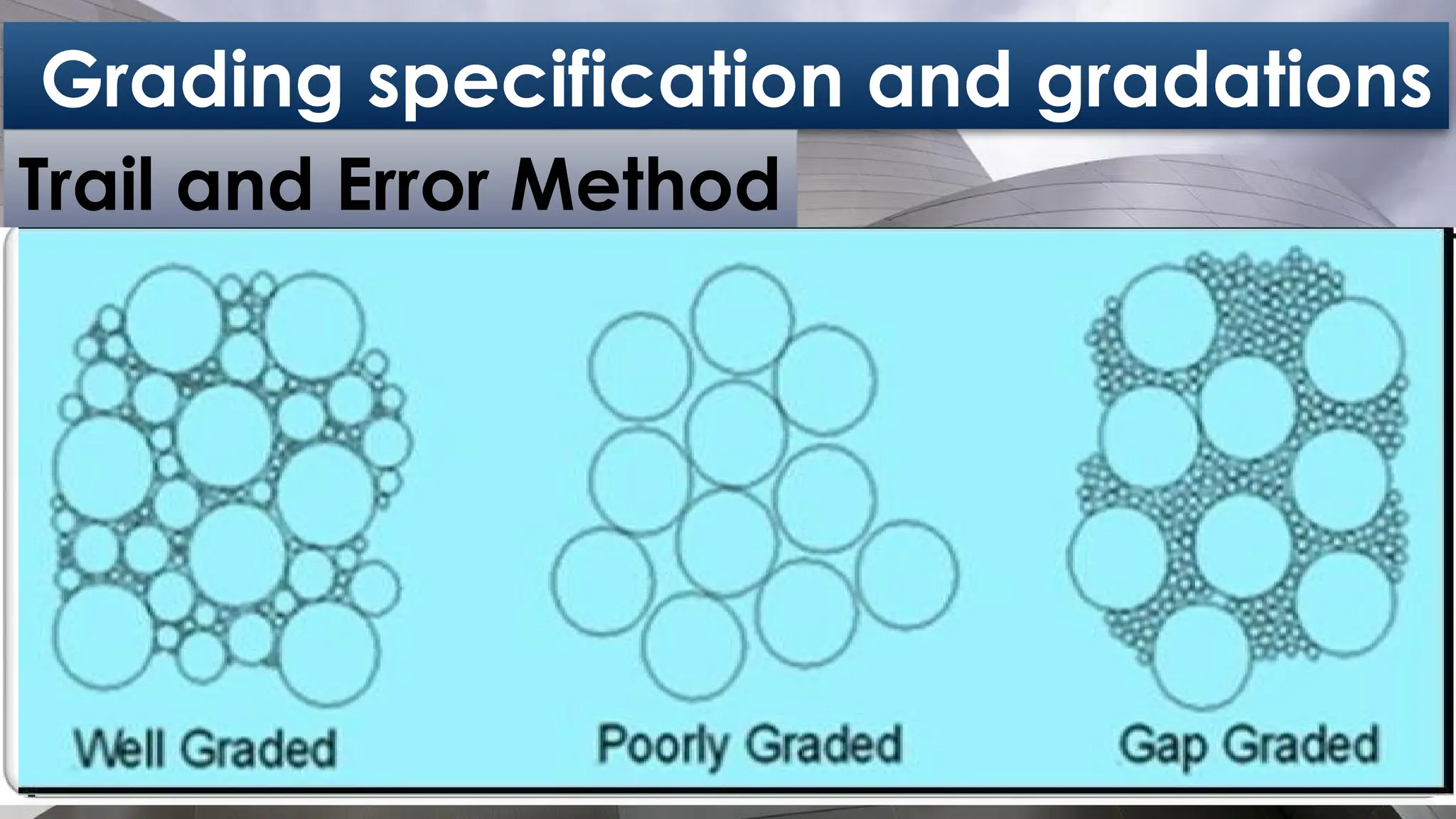

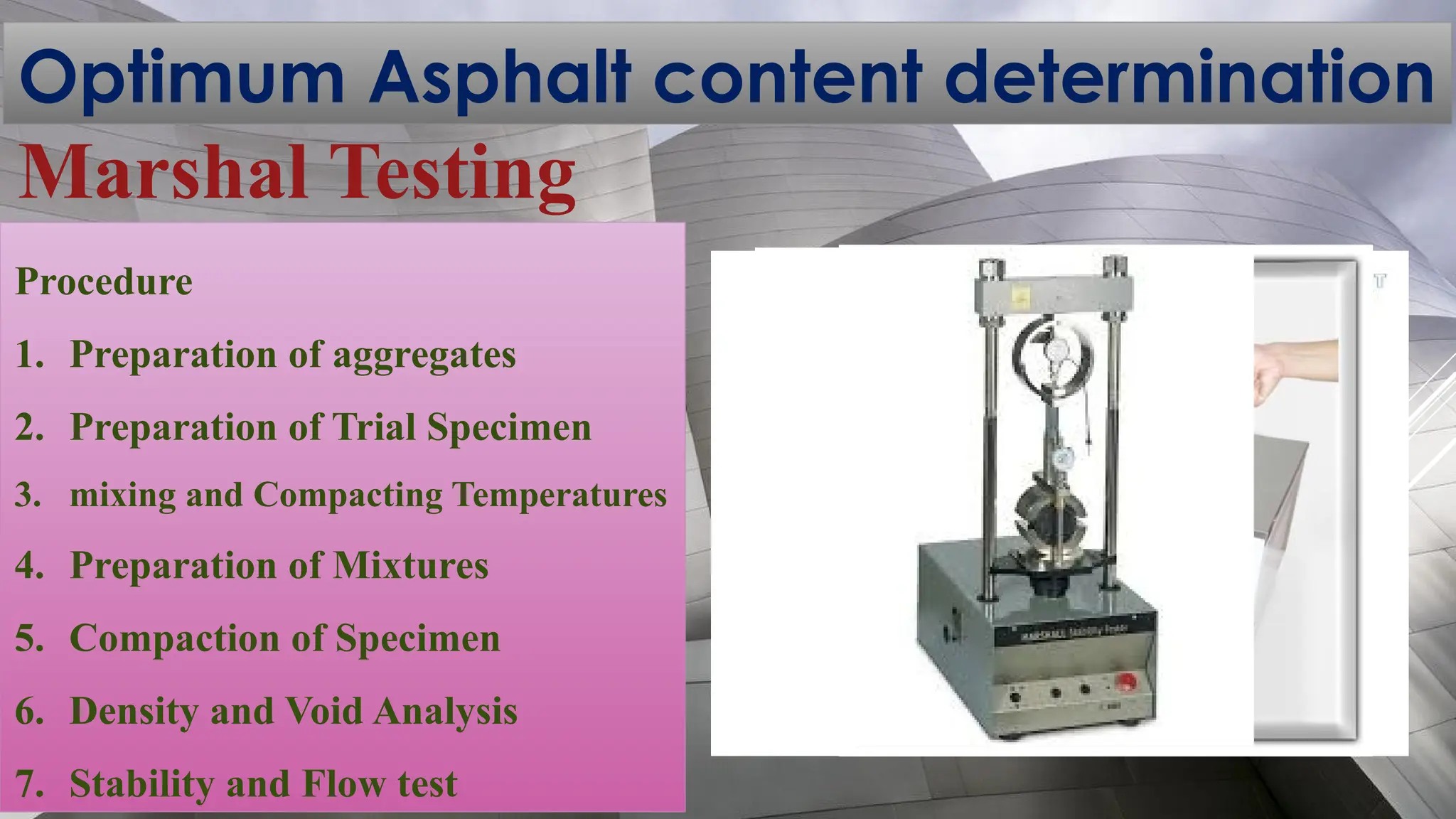

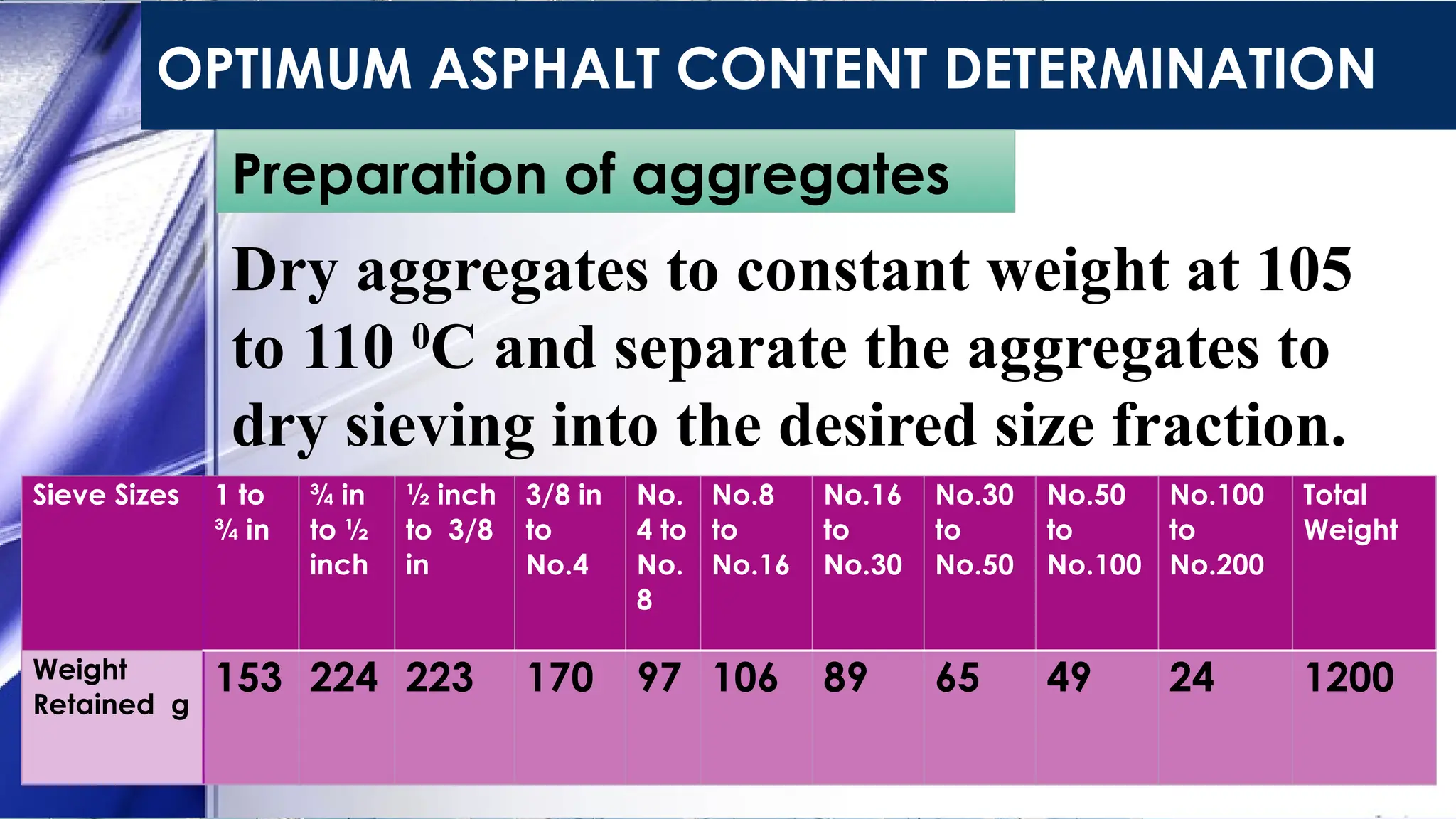

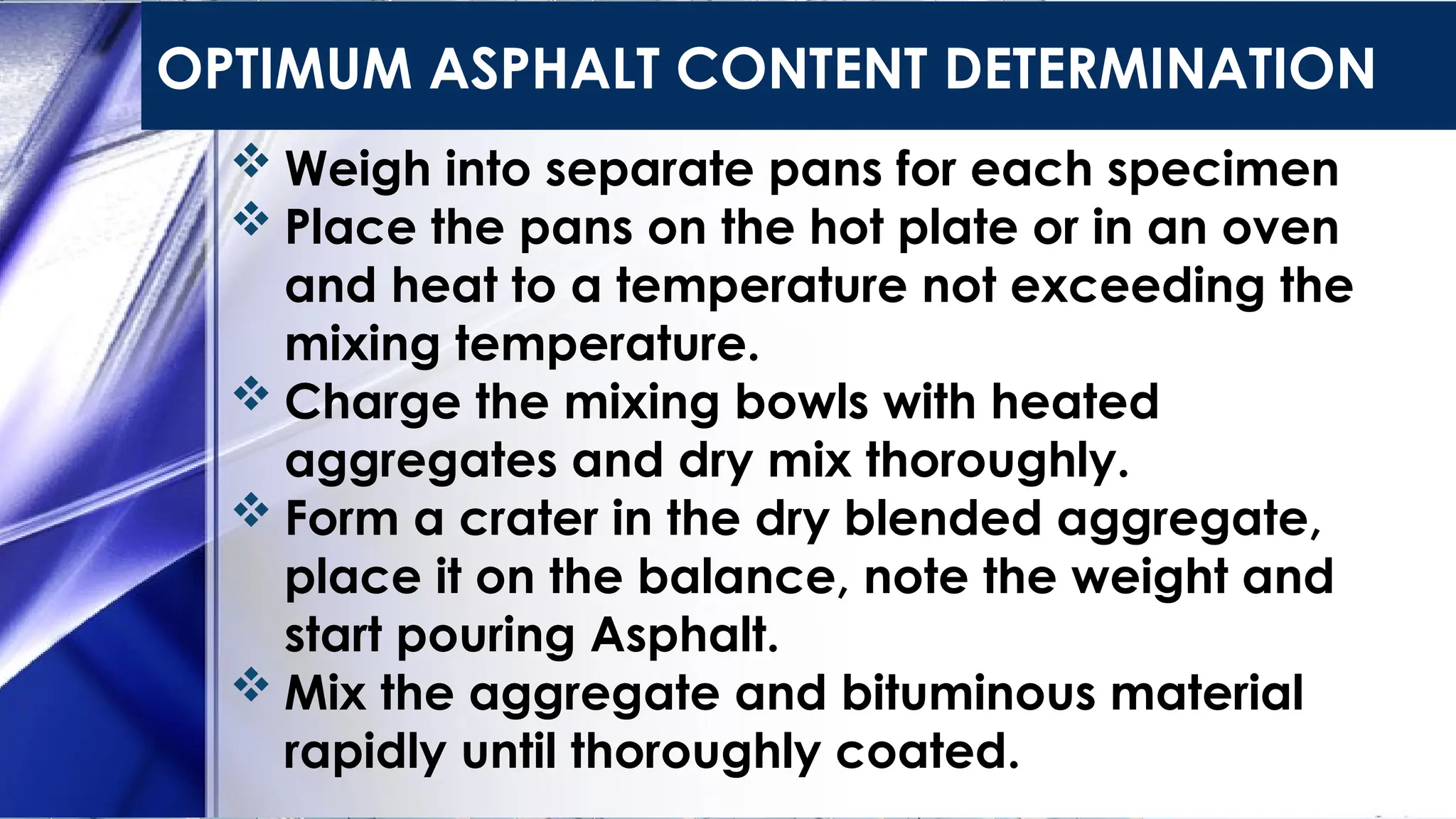

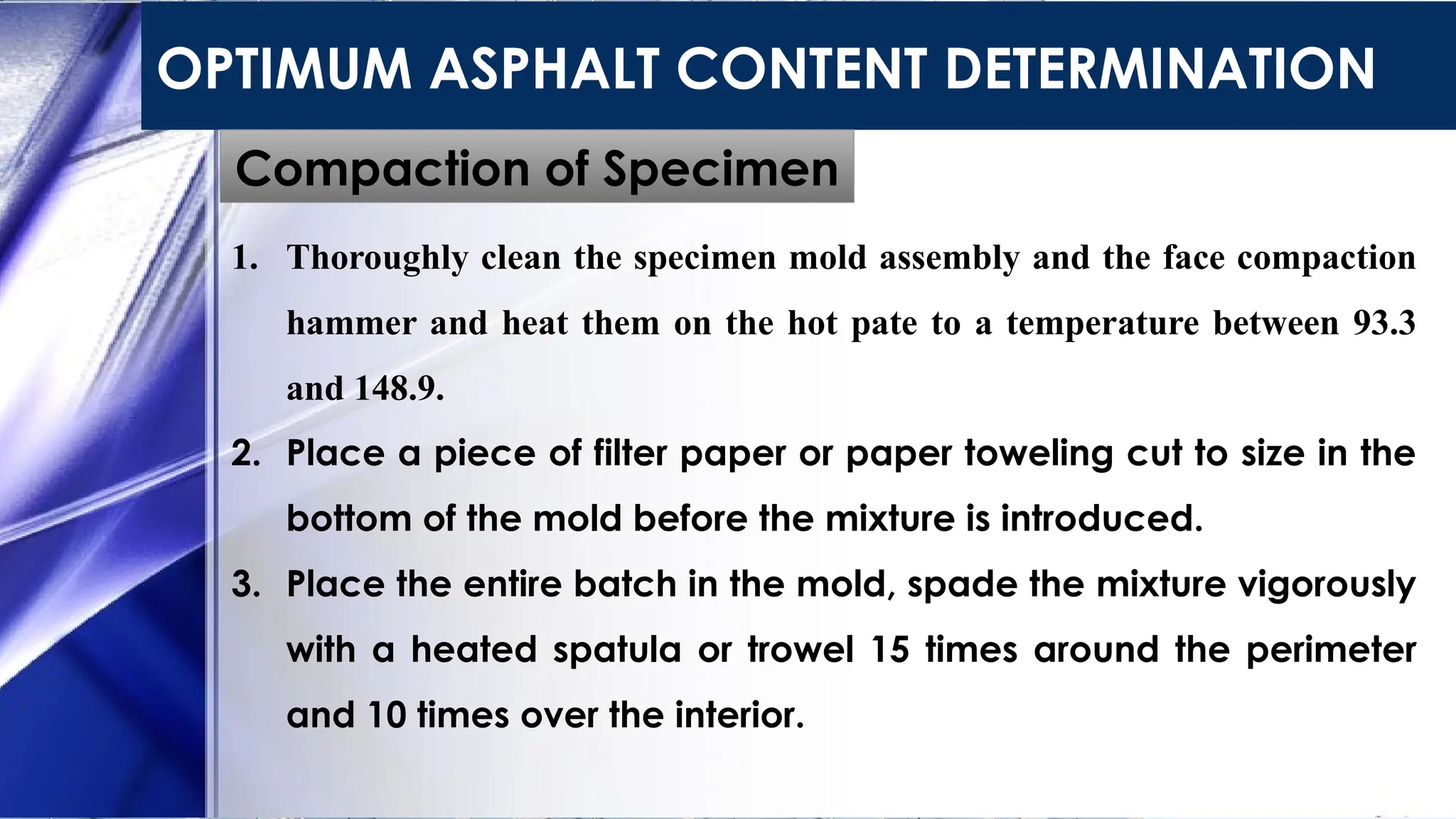

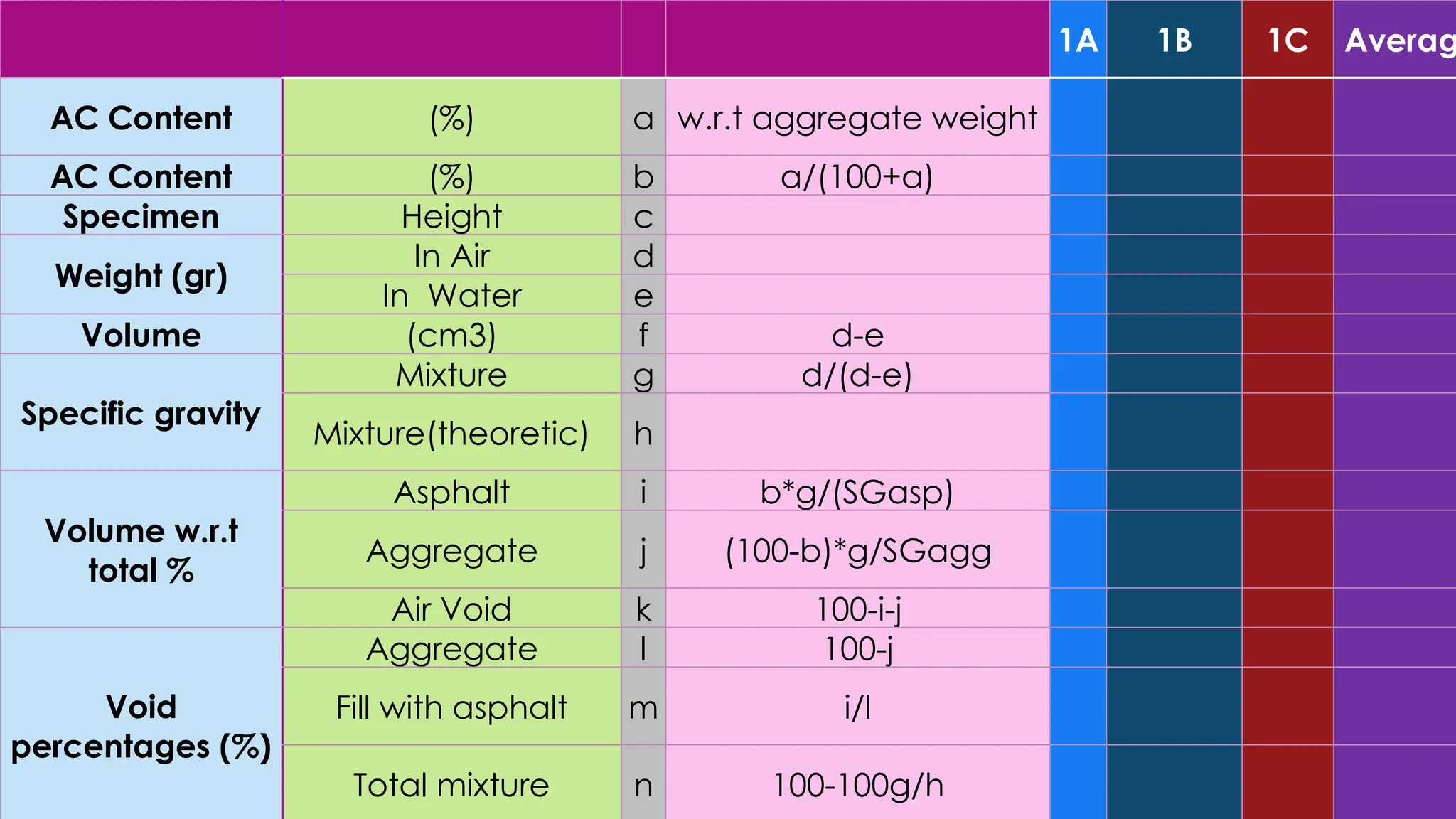

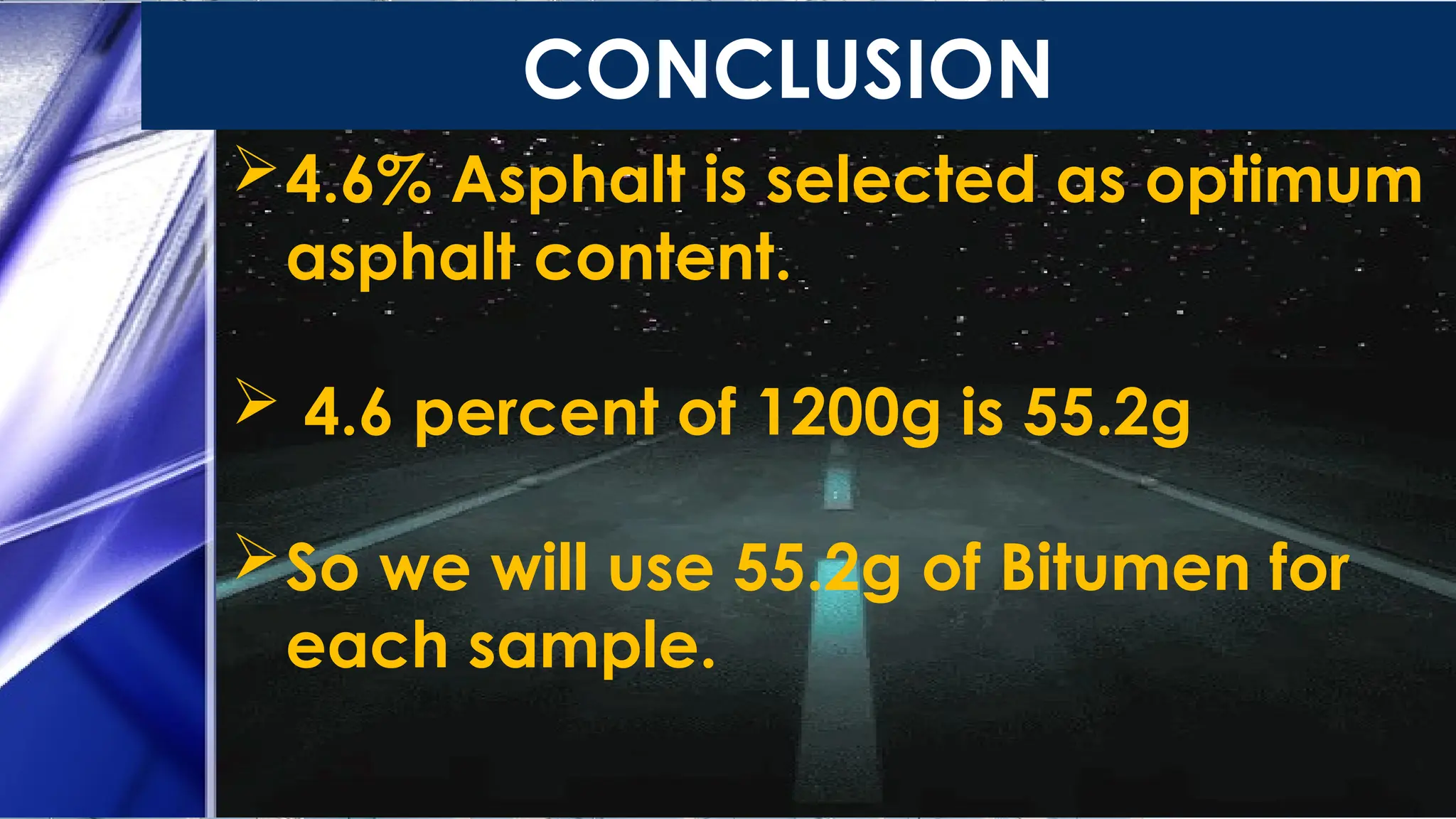

This presentation provides a comprehensive overview of the Job Mix Formula (JMF) used for designing Hot Mix Asphalt (HMA) layers of road. It explains the complete aggregate blending process, including selection, proportioning, and evaluation of aggregate gradation to meet specification requirements. The slides also cover the full procedure of the Marshall Stability and Flow Test, detailing sample preparation, compaction, testing, and interpretation of results. The presentation is designed to help engineers, students, and professionals understand the fundamentals of HMA mix design, ensuring proper performance, durability, and quality control in pavement construction.

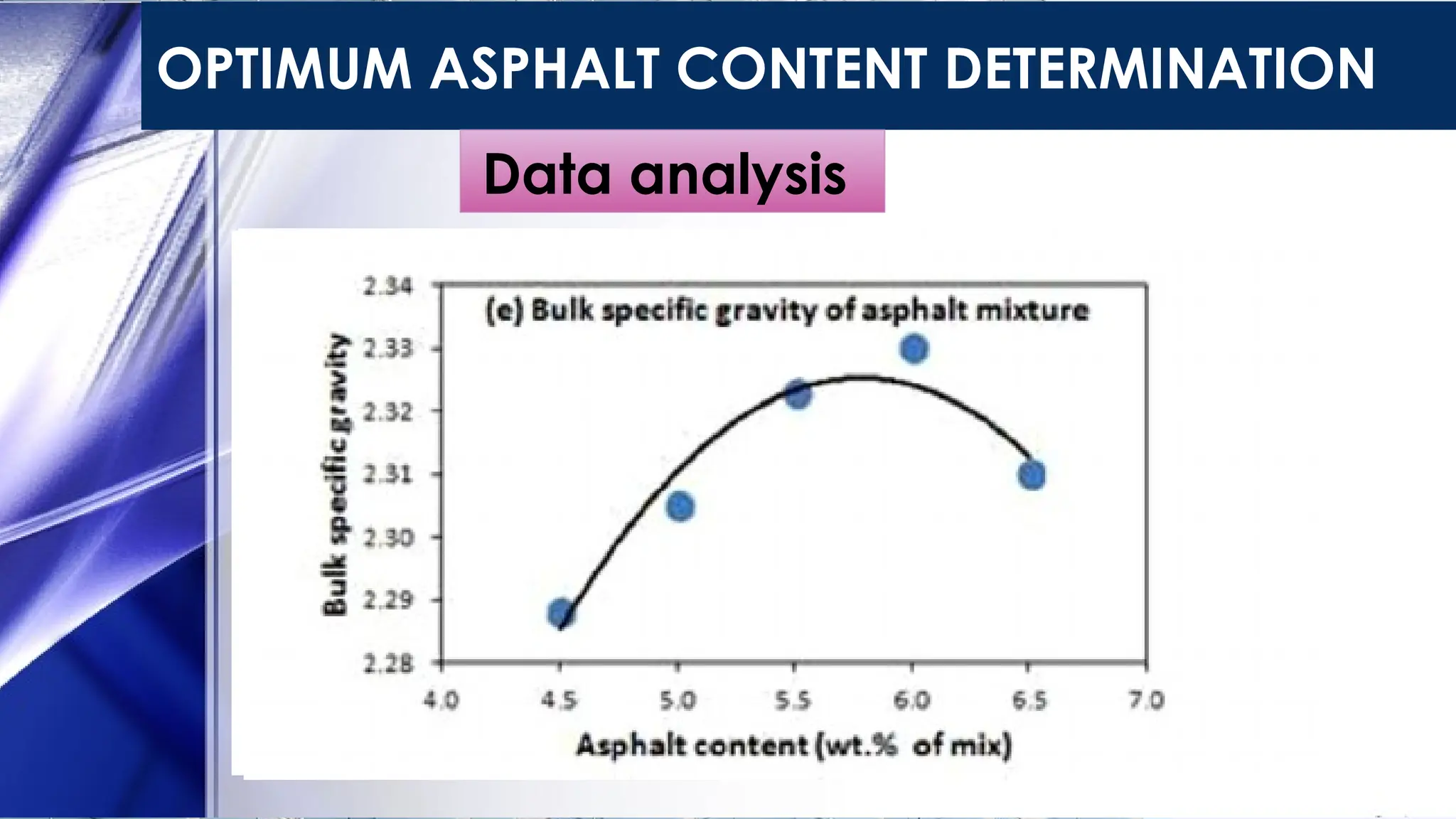

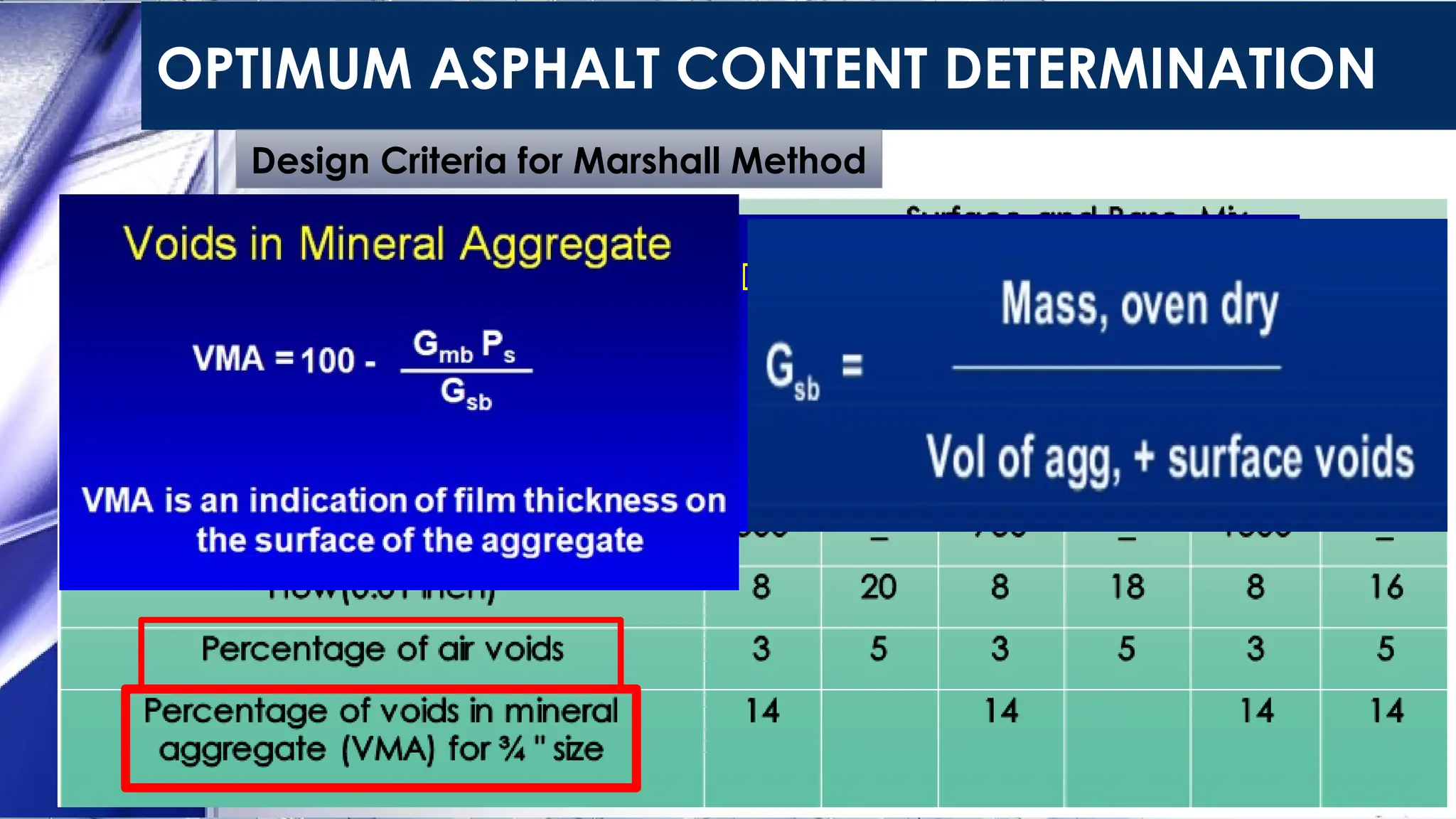

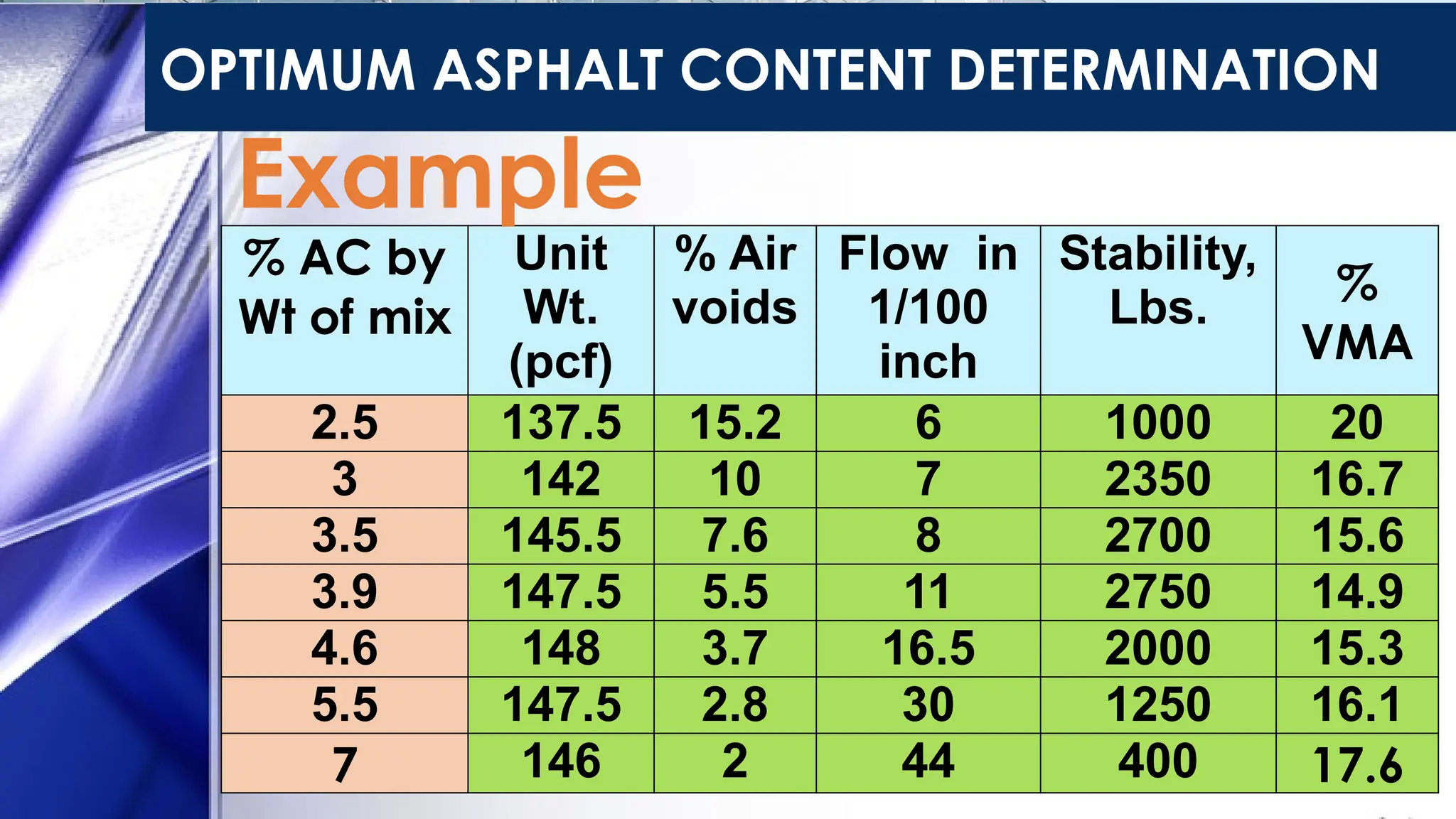

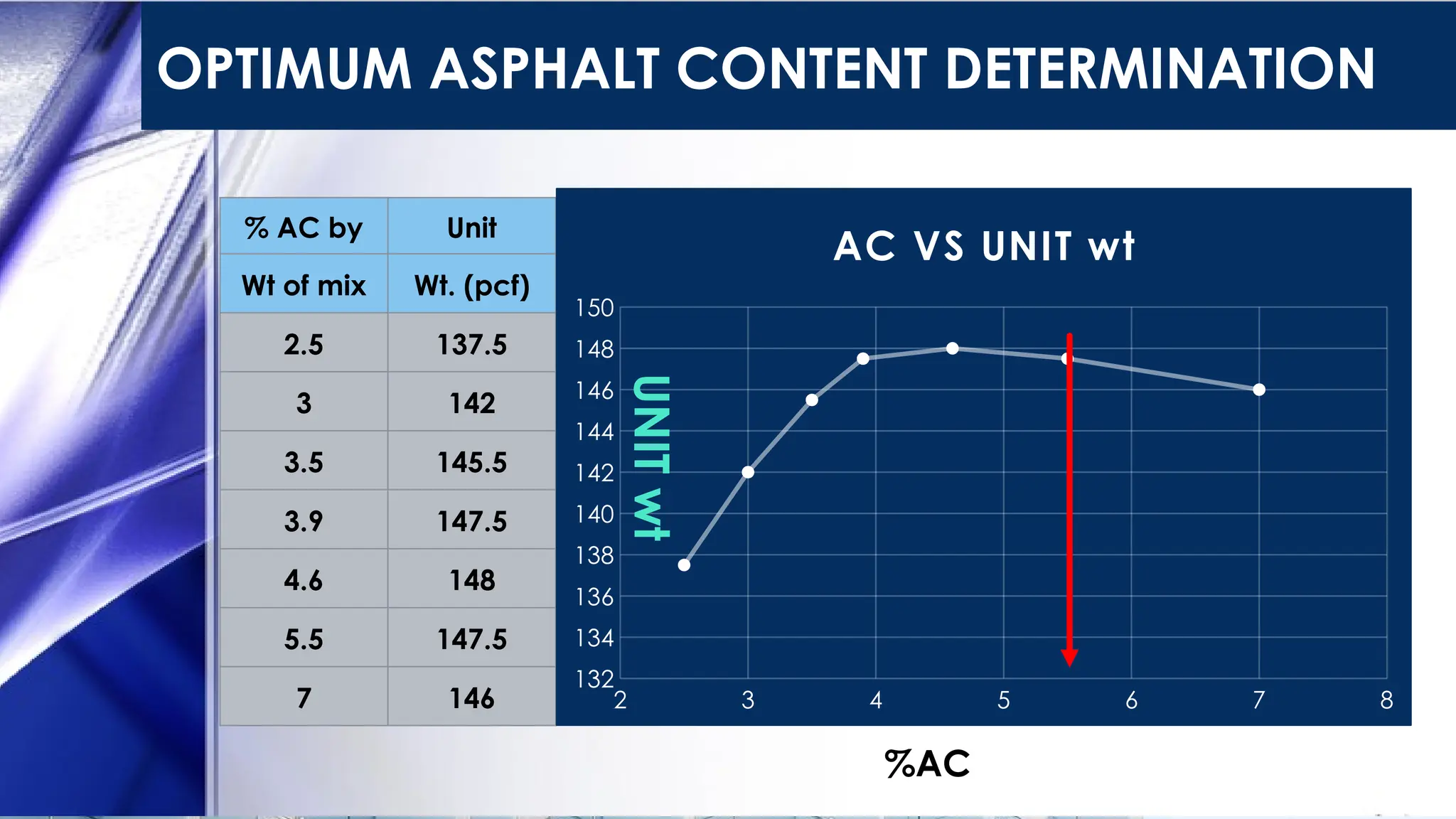

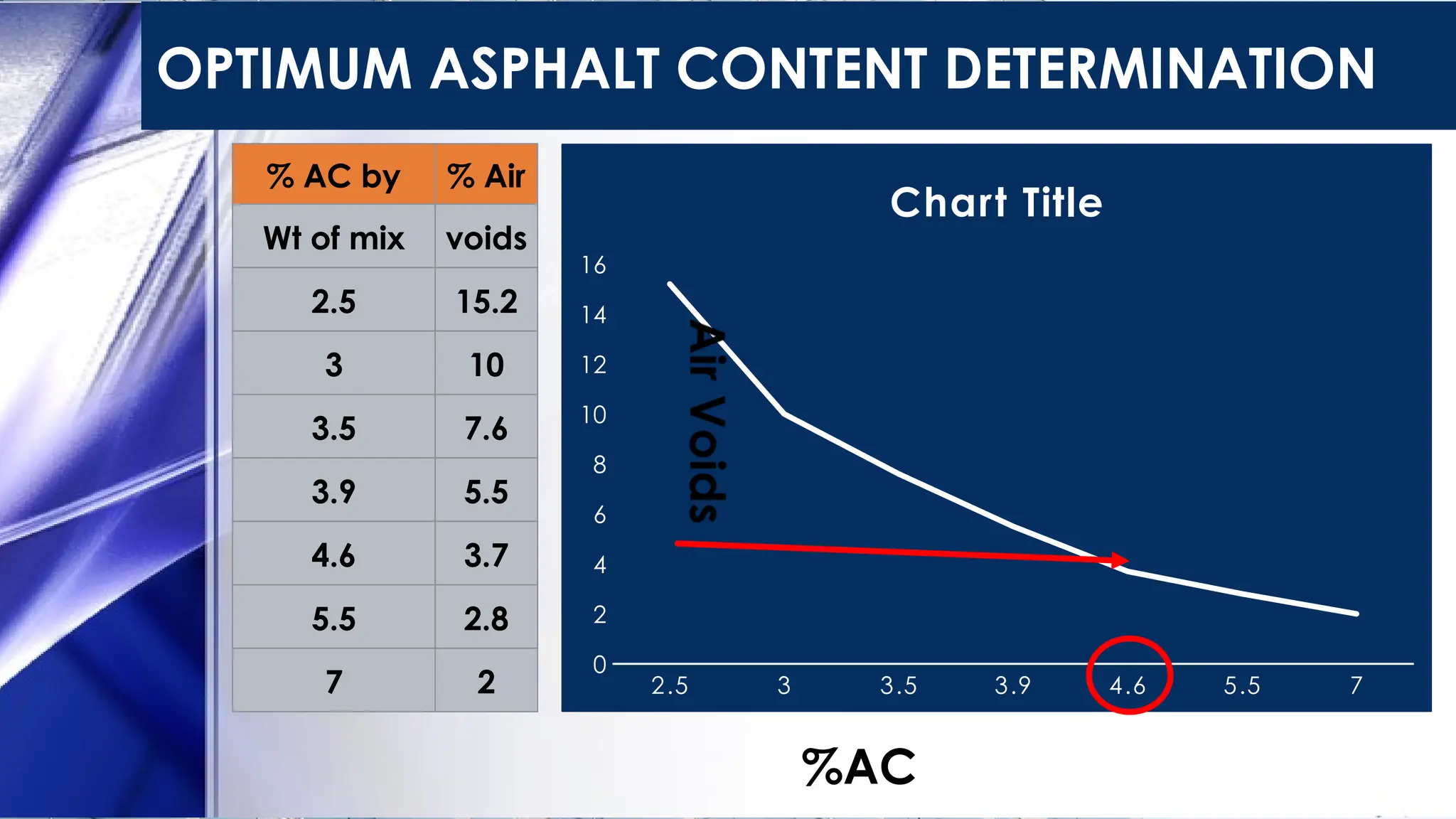

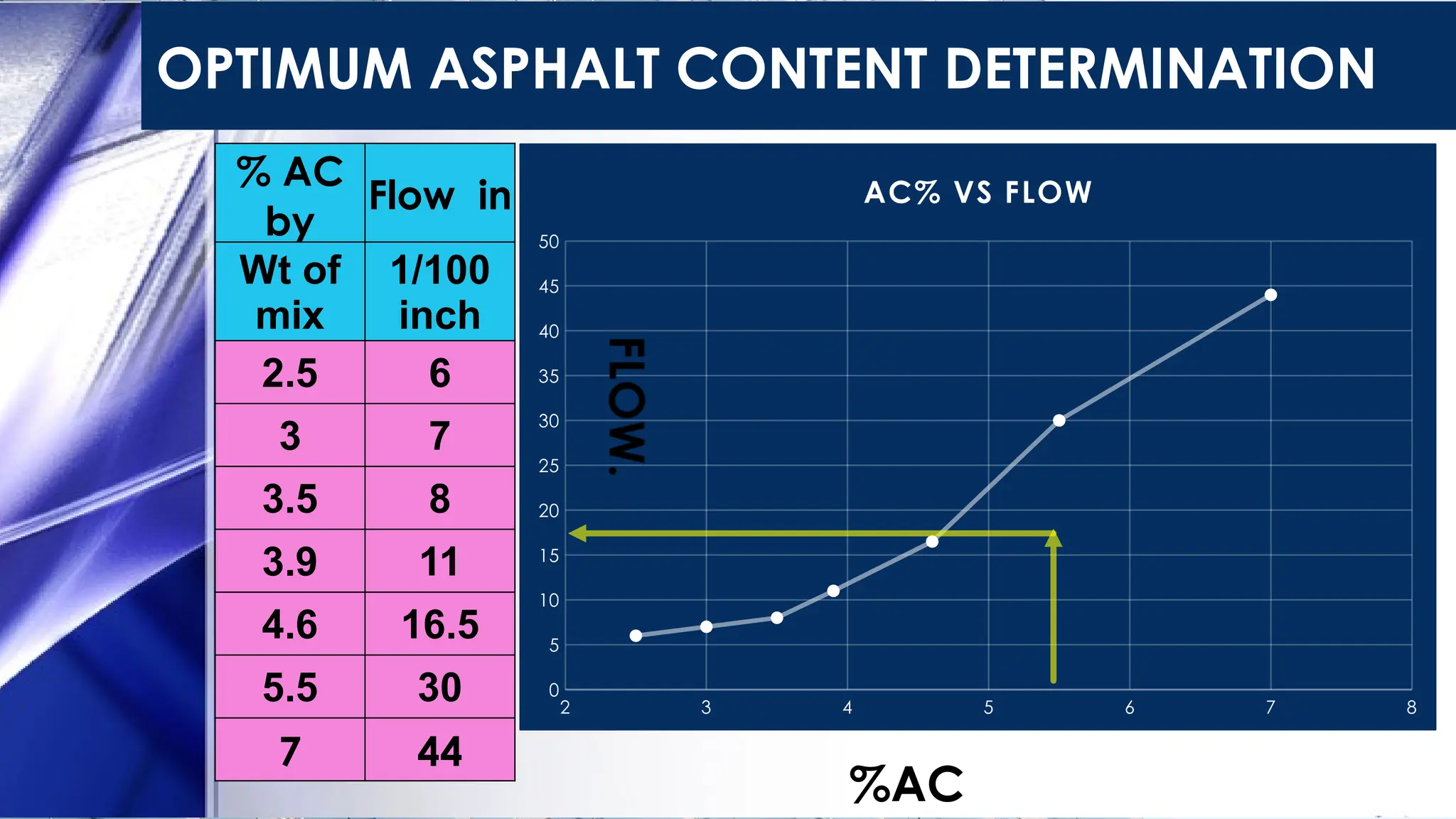

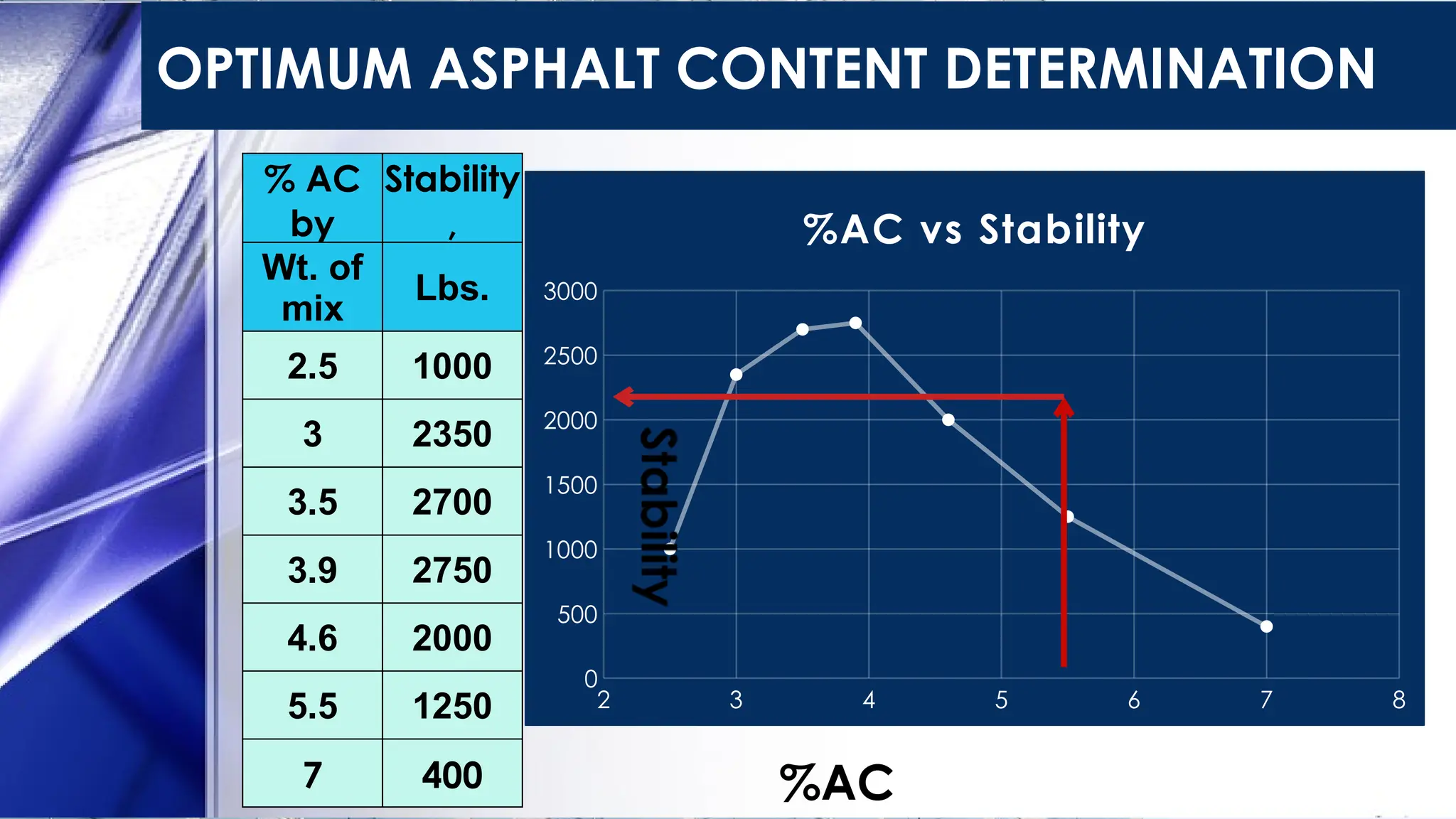

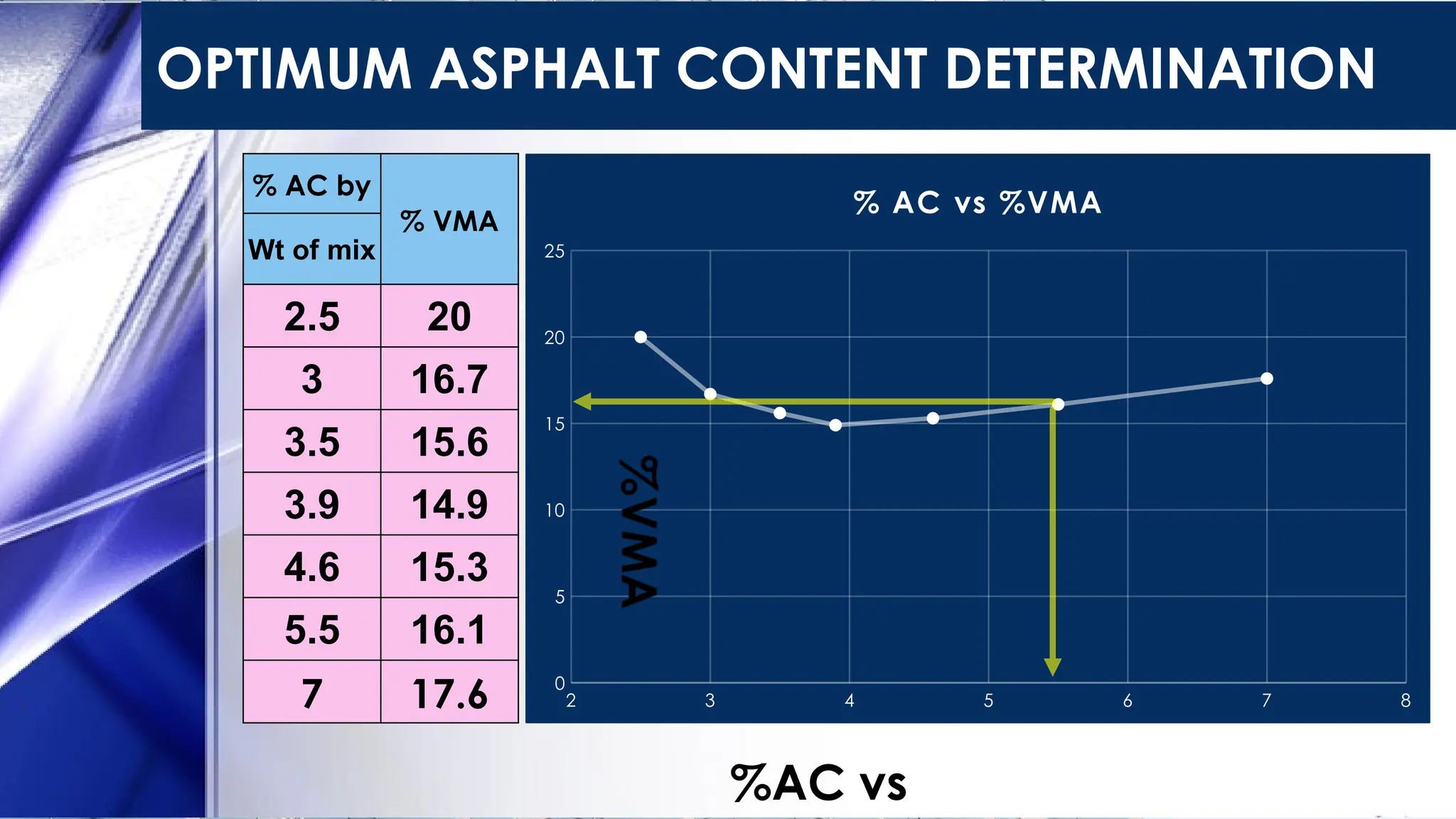

This presentation also highlights key parameters influencing mix performance, such as air voids, VMA, VFB, and optimum binder content. It serves as a useful reference for both field engineers and laboratory technicians involved in pavement design and quality assurance.