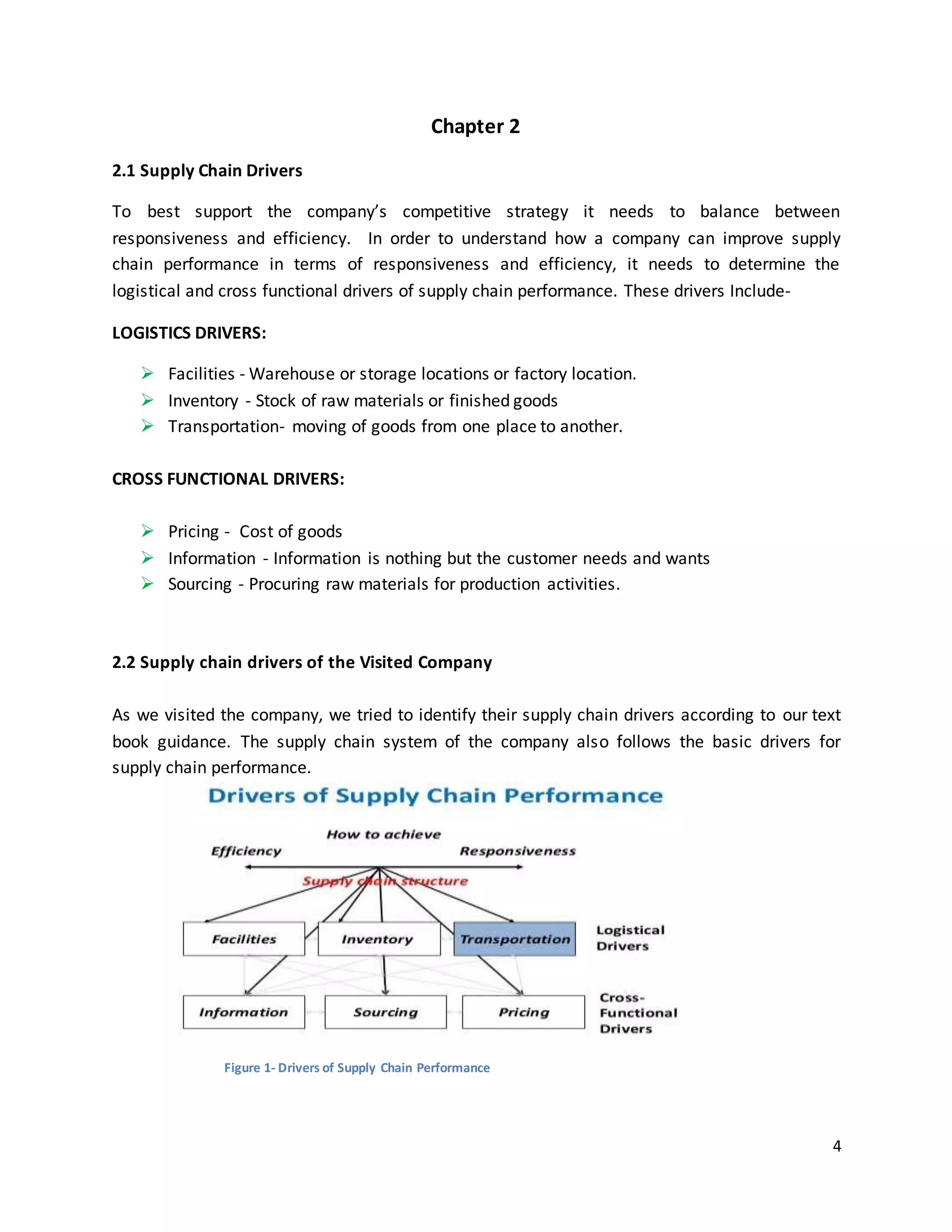

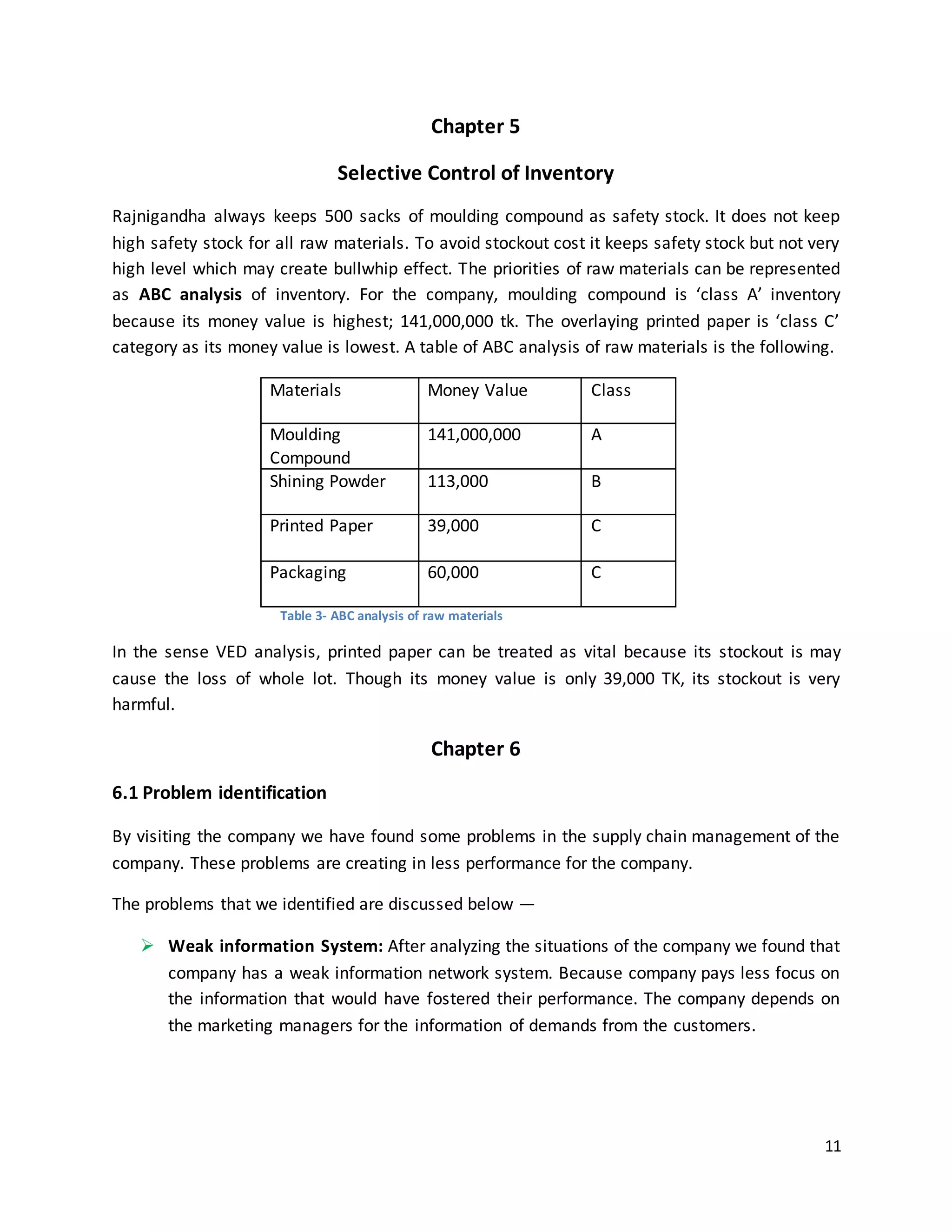

Rajnigandha Melamine Ltd produces melamine tableware and stocks finished goods in its warehouse for customer pickup. It sources raw materials from China and Taiwan. The company focuses on efficiency over responsiveness. It was identified that the company has weak information systems, lacks customer interaction, does little research and development, sells products on credit causing bad debt, and sometimes produces faulty colored products. Recommendations include collaborating with supply chain partners and integrating an information network system.