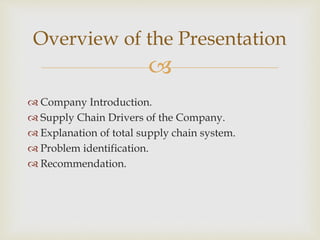

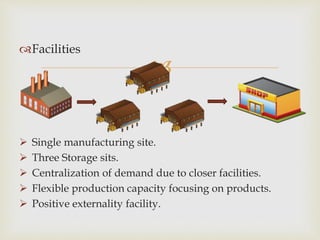

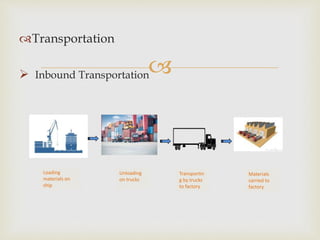

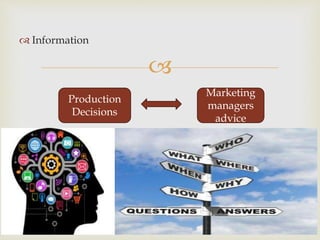

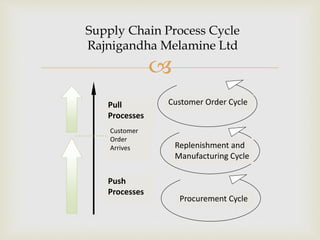

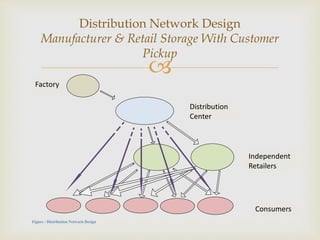

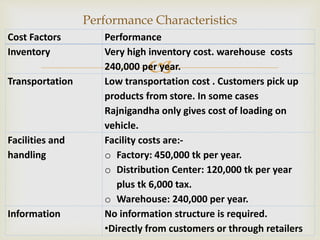

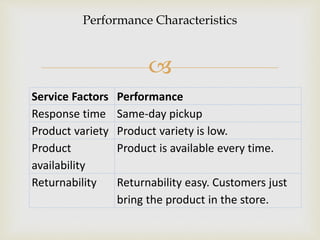

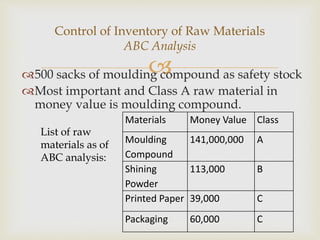

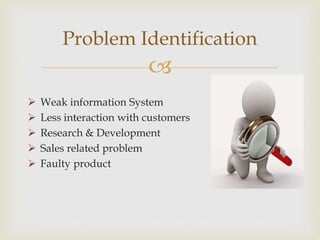

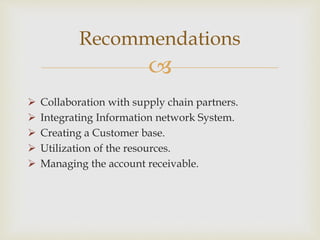

This presentation summarizes the supply chain of Rajanigandha Melamine and Plastic. It introduces the company and outlines its supply chain drivers including facilities, inventory, transportation, information, and sourcing and pricing strategies. It then describes the company's supply chain processes and distribution network design. It analyzes the company's performance in terms of costs and service and identifies problems around its information systems, customer interaction, research and development, and sales. Finally, it provides recommendations to improve collaboration, implement an information system, create a customer base, optimize resource utilization, and manage accounts receivable.