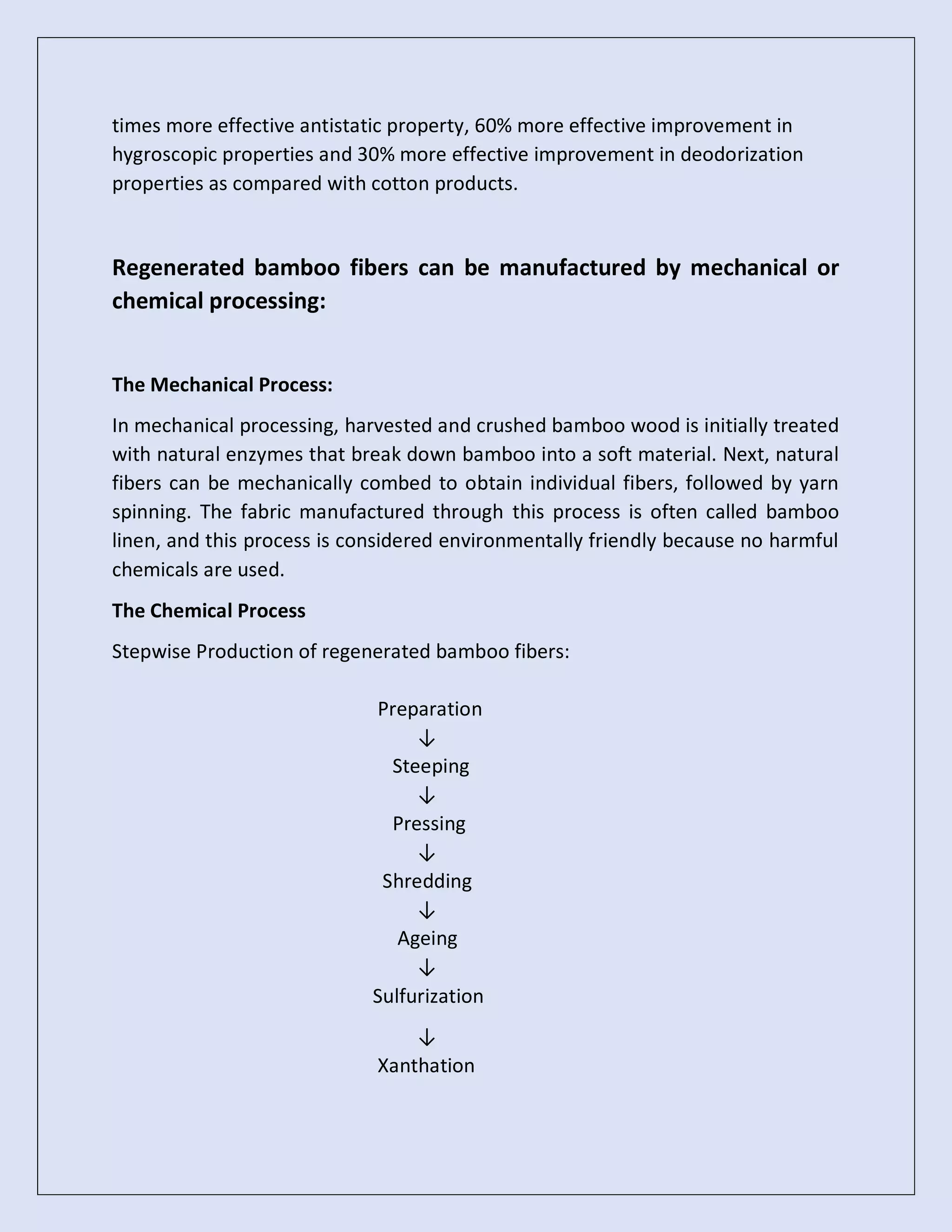

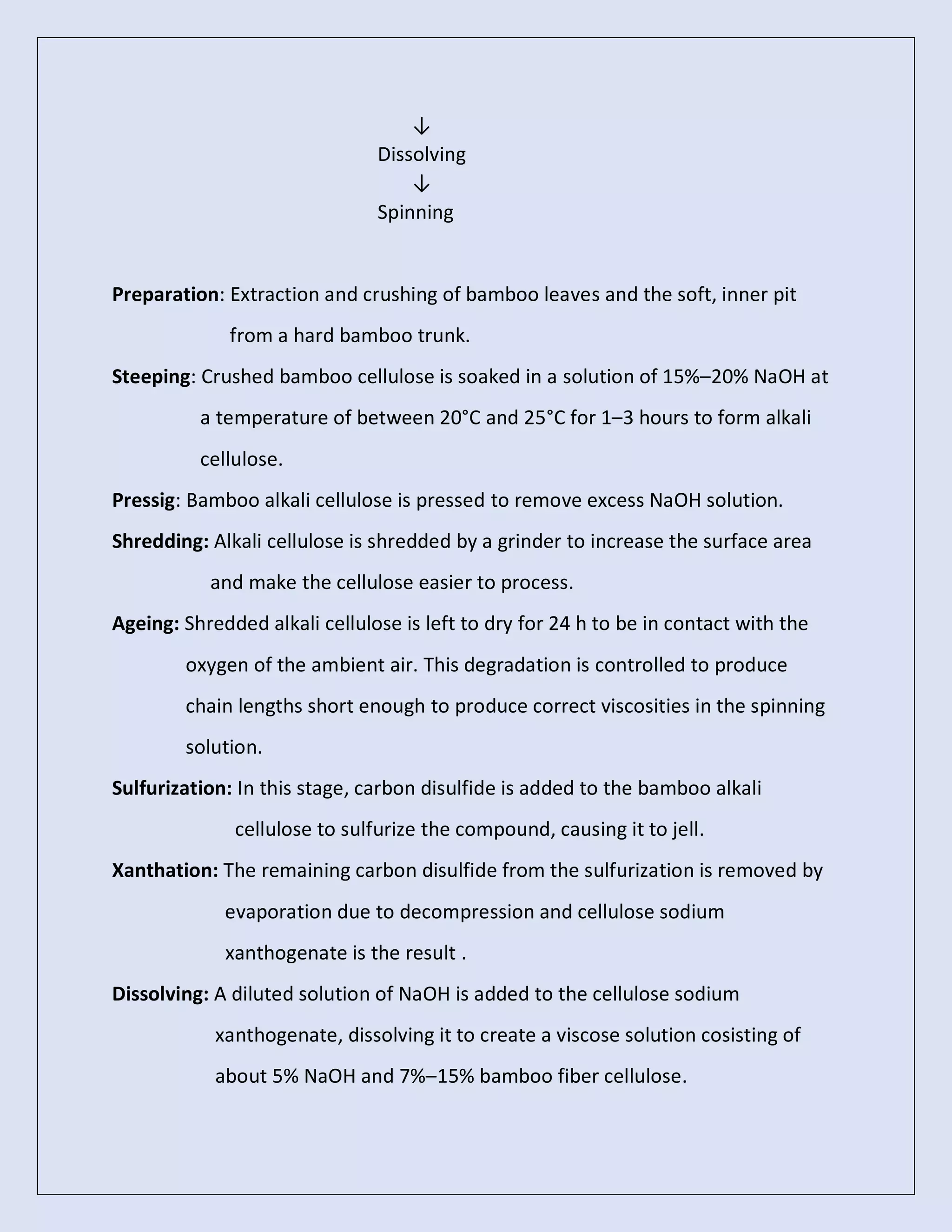

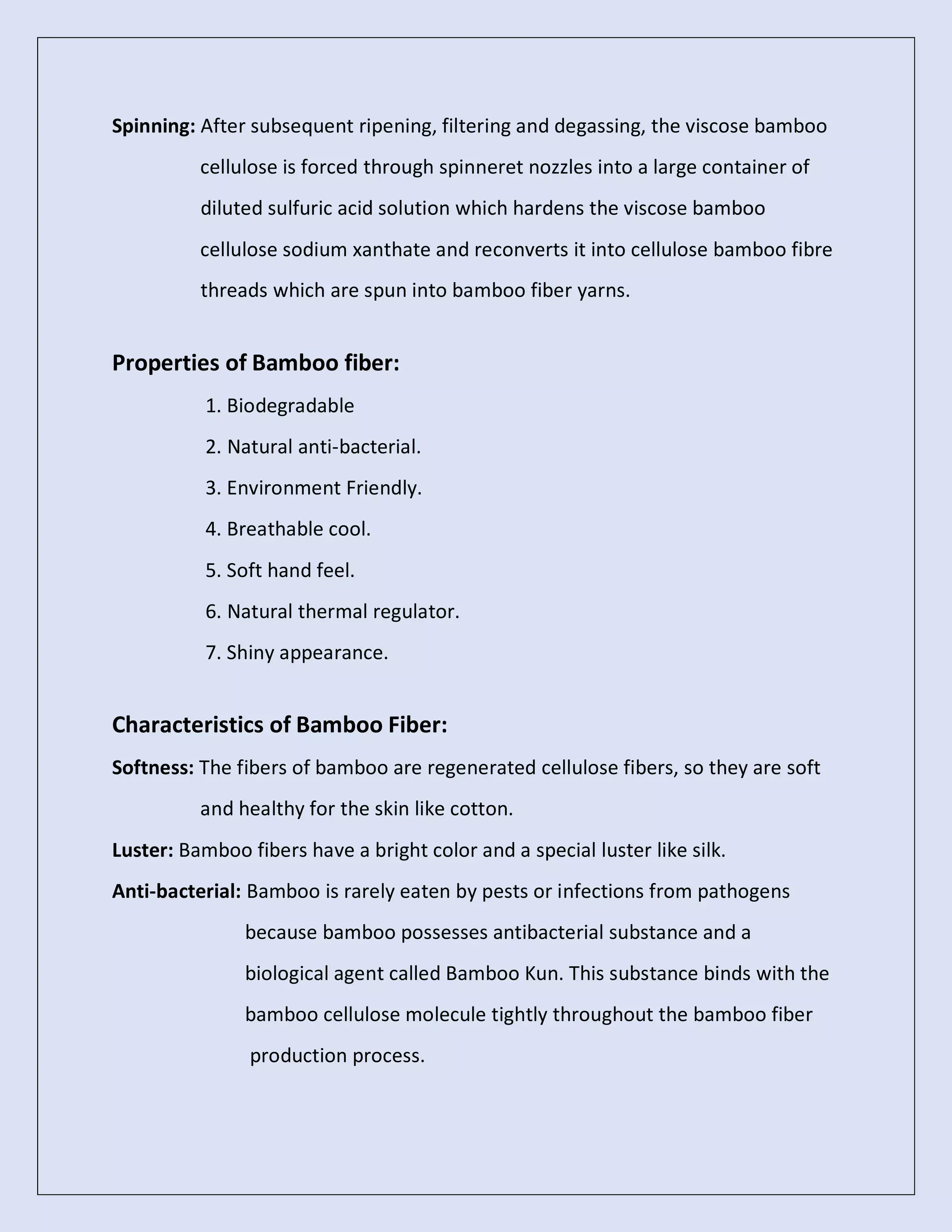

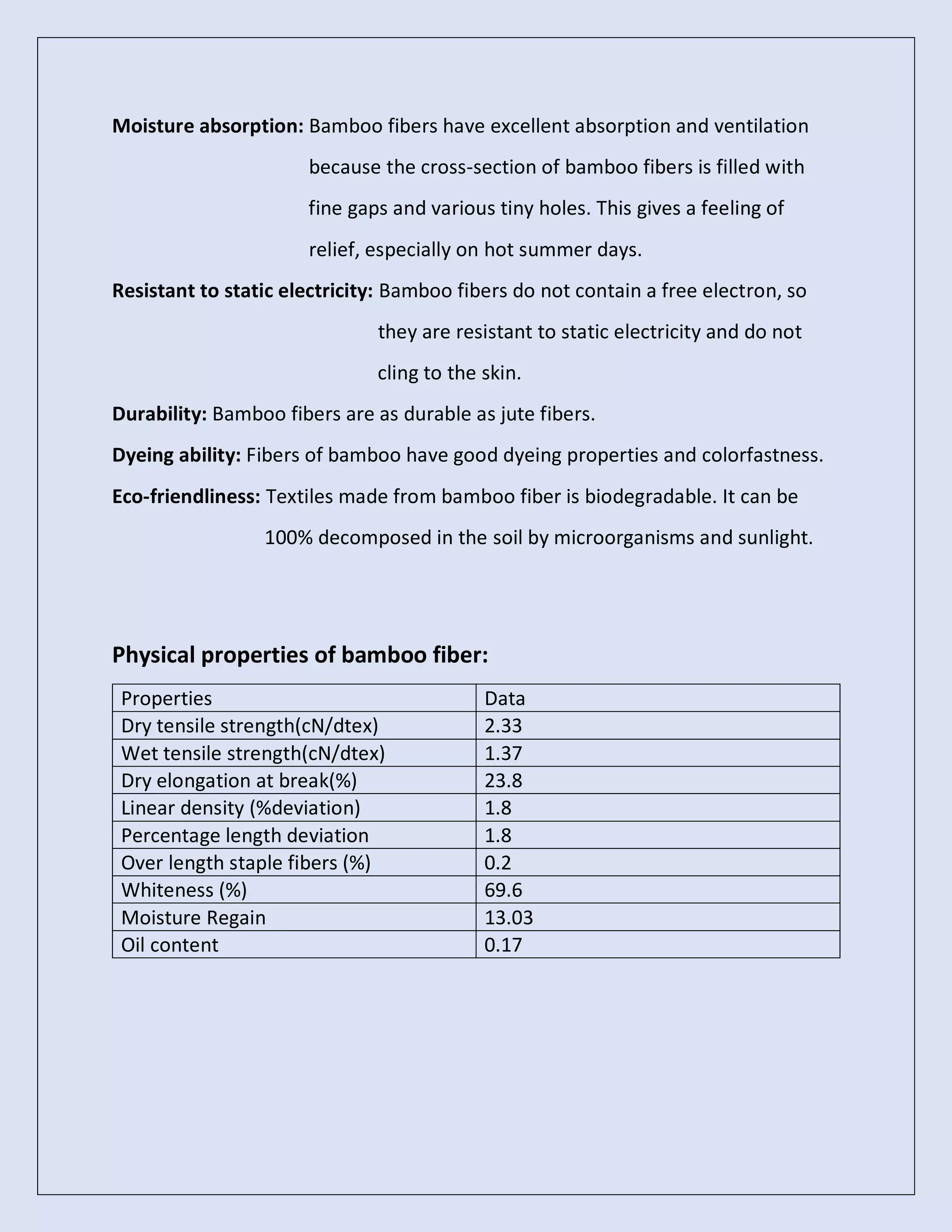

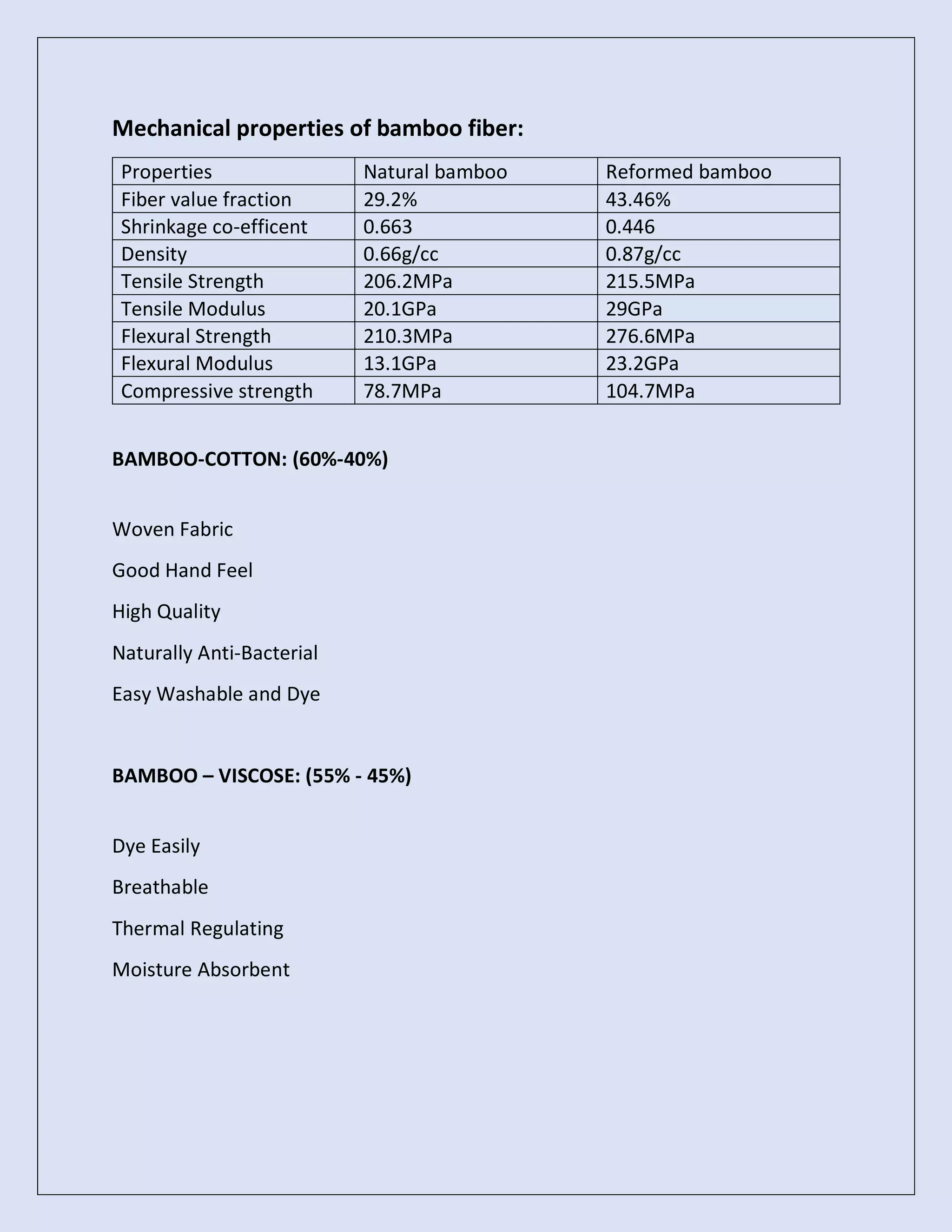

This document provides information about bamboo fiber, including its structure, manufacturing process, properties, uses, and advantages/disadvantages. Bamboo fiber is a cellulosic fiber produced from bamboo plants through an alkaline hydrolysis and bleaching process. It has properties such as good moisture absorption, biodegradability, and antibacterial effects. Common uses of bamboo fiber include clothing, towels, masks, and furnishings due to its softness and sustainability. Advantages include sweat absorption and UV resistance while disadvantages include potential pilling and shrinkage.